Diammonium phosphate synergistic fertilizer and preparation method thereof

A diammonium phosphate and diammonium phosphate-containing technology, applied in ammonium orthophosphate fertilizers, alkaline orthophosphate fertilizers, phosphate fertilizers, etc., can solve the problems of low utilization rate of diammonium phosphate, improve crop quality and yield, reduce The effect of ammonia volatilization loss and improving fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

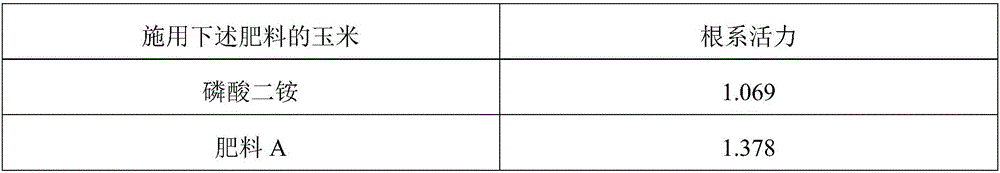

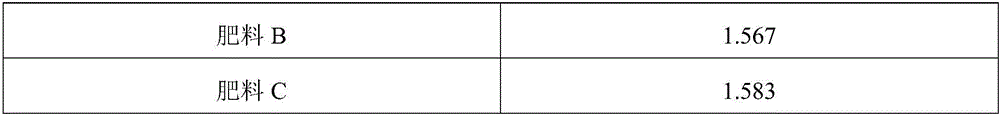

Examples

Embodiment 1

[0035] 1) brown coal is crushed to 100 mesh;

[0036] 2) Add 1kg lignite, 10kg water, and 100g composite flora to the reactor; wherein, the composite flora is a mixture of Lentinus edodes, Trichoderma and Bacillus subtilis, and the mixing ratio is 1:1:0.5 by weight; stir evenly , the stirring rate is 150r / min, add 100g of 0.2% sodium hydroxide solution and continue to stir; then add 10g mixed amino acid salt and 20g zinc methionine and stir for 0.5h; the mixed amino acid salt is sodium nucleotide, sodium tyrosine and The mixing of sodium glutamine, the mixing ratio is 1:0.5:0.2 by weight;

[0037] 3) Filter the above mixture for 2 times. The filter adopts a CT bucket plate and frame filter produced by Haining Zhengxing Special Filter Equipment Manufacturing Co., Ltd., then heat the supernatant to 110°C for 3 hours, and concentrate until the solid content is 12%, prepared as the synergist.

[0038] 4) Put 1 ton of diammonium phosphate into the drum granulator and stir evenly,...

Embodiment 2

[0040] 1) brown coal is crushed to 80 mesh;

[0041] 2) 1 kg of weathered coal, 20 kg of water, and 200 g of composite flora are added to the reactor; wherein, the composite flora is a mixture of Trichoderma, Bacillus megaterium and Bacillus subtilis, and the mixing ratio is 1:1.5:0.5 by weight; Stir evenly at a stirring rate of 150r / min, add 200g of 0.3% sodium hydroxide aqueous solution and continue stirring; then add 10g of mixed amino acid salt and 20g of zinc methionine and stir for 0.5h; the mixed amino acid salt is sodium glycinate, sodium tyrosine and The mixing of sodium tryptophanate, the mixing ratio is 1:0.5:0.2 by weight;

[0042] 3) Filter the above mixture for 2 times. The filter adopts a CT barrel plate and frame filter produced by Haining Zhengxing Special Filter Equipment Manufacturing Co., Ltd., and then heat the supernatant to 120° C. for 3 hours, and concentrate until the solid content is 30%.

[0043]4) Put 1 ton of diammonium phosphate into the drum gr...

Embodiment 3

[0045] 1) brown coal is crushed to 100 mesh;

[0046] 2) 1 kg of weathered coal, 20 kg of water, and 200 g of composite flora are added to the reactor; wherein, the composite flora is a mixture of Trichoderma, Bacillus megaterium and Bacillus subtilis, and the mixing ratio is 1:1.5:1 by weight; Stir evenly at a stirring rate of 200r / min, add 500g of 0.3% sodium hydroxide aqueous solution and continue stirring; then add 10g of mixed amino acid salt and 20g of zinc methionine and stir for 0.5h; the mixed amino acid salt is sodium glycinate, sodium tyrosine and The mixing of sodium glutamine, the mixing ratio is 1:0.6:0.3 by weight;

[0047] 3) Centrifuge the above mixture. The centrifugal separation adopts the PQSB flat-panel full flip centrifuge produced by Zhangjiagang Leyu Electromechanical Equipment Factory, and then heat the supernatant to 120° C. for 4 hours, and concentrate to a solid content of 60%. .

[0048] 4) Put 1 ton of diammonium phosphate into the drum granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com