Heat-resistant black sand cooking device and preparation process method thereof

A cooker and black sand technology, applied in clay products, other household utensils, applications, etc., can solve the problems of insufficient heat resistance, only suitable for heat resistance, not suitable for high fire of heating appliances, and rapid fire cooking, etc. To achieve the effect of optimizing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be further described in detail below in conjunction with specific examples.

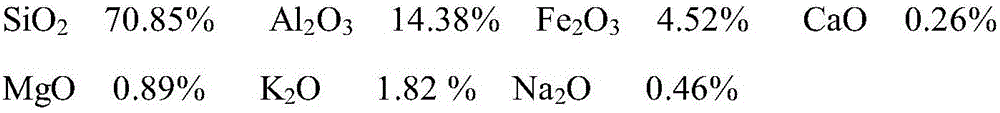

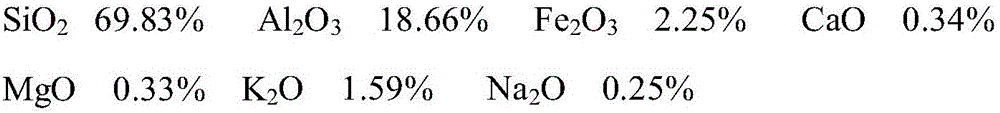

[0030] The preparation method of this patent mainly conducts systematic and in-depth research on the amount of spodumene added, the material particle gradation, and the water absorption rate of the product, and formulates the best production process and process parameters to ensure the heat resistance of the product.

[0031] 1) If the amount of spodumene added is less than 40%, the heat resistance cannot reach 800-20 degrees. If the amount of spodumene added is more than 45%, the heat resistance will not be improved. On the contrary, the molding performance of the product is poor, so it is set at 40-45 % is the best;

[0032] 2) The grading of raw material particles in formula composition is the key to affect the heat resistance of products: uniform distribution of raw material particles, too thick or too fine will lead to insuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com