Fixtures for motor housings

A technology of motor housings and tooling fixtures, which is applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of cumbersome clamping, low processing efficiency, and complex structure, and achieve simple structure, improved processing efficiency, and clamping Easy and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

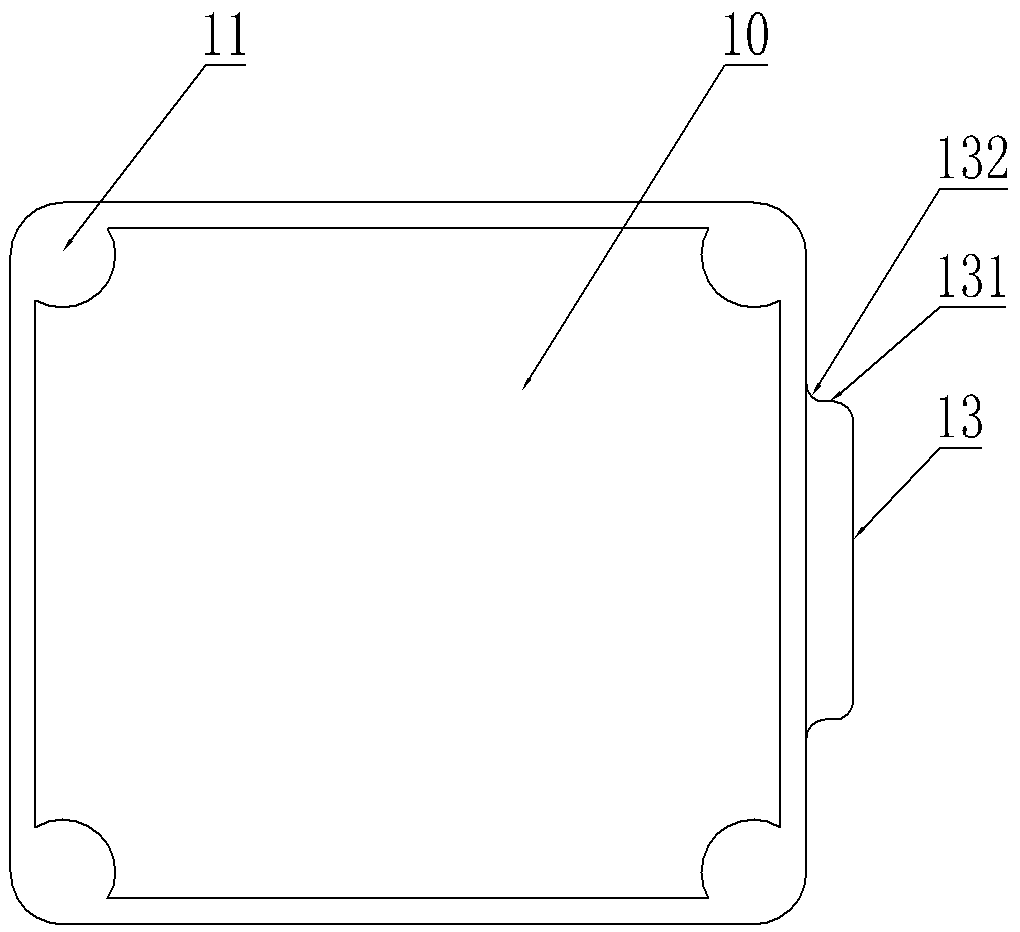

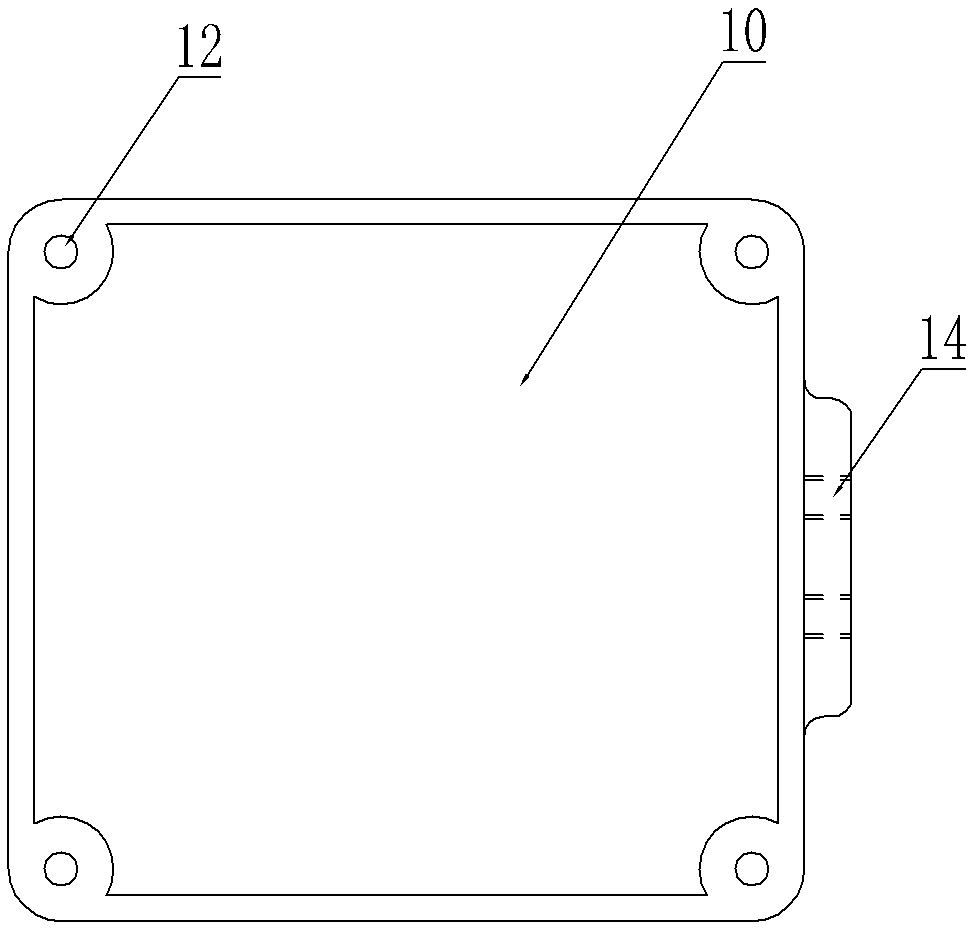

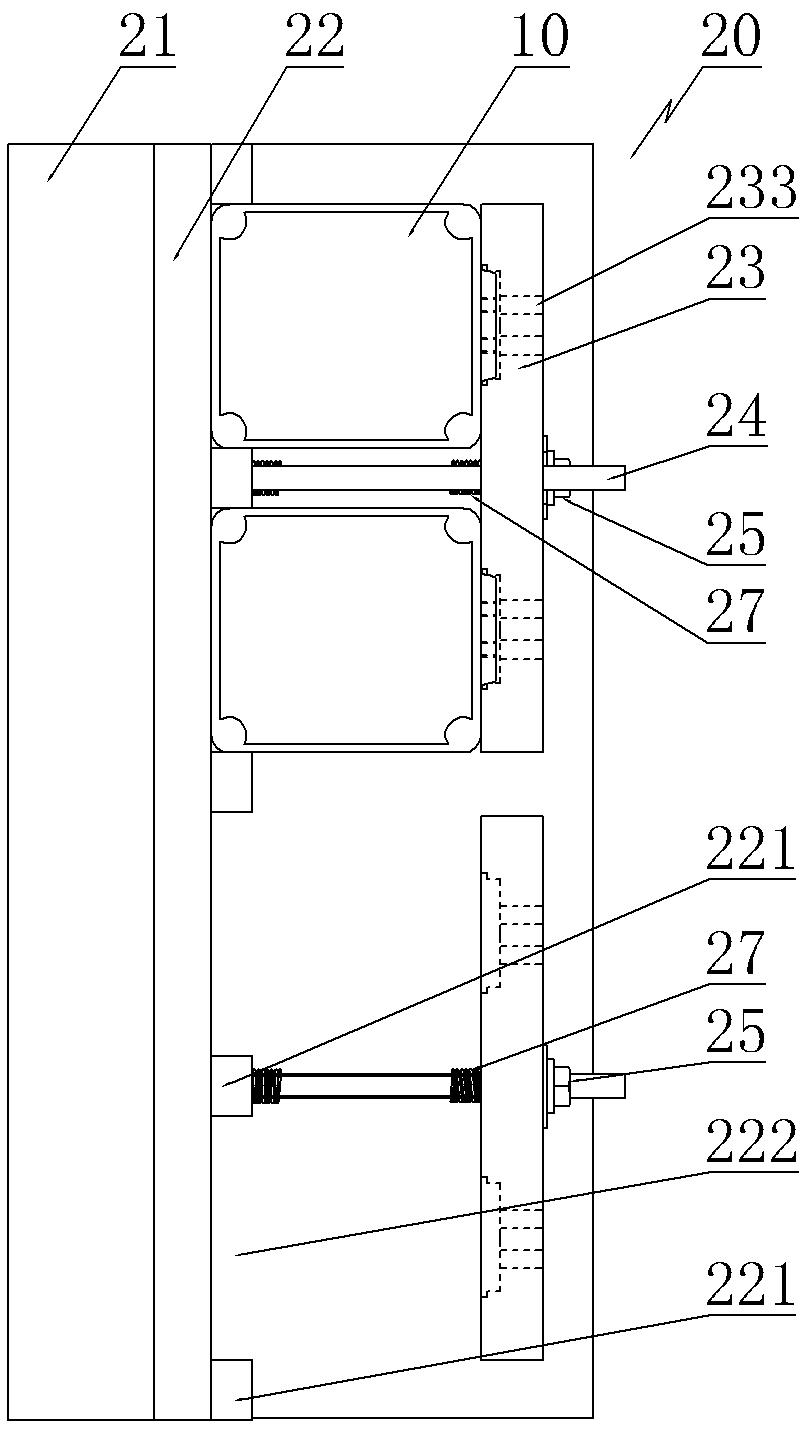

[0019] Such as Figure 1~Figure 6 As shown, the tooling fixture 20 of the motor housing includes a base plate 21, a support plate 22, a pressure plate 23 and bolts 25, the support plate 22 is vertically fixed on the base plate 21, and one side end surface of the support plate is provided at intervals along the length direction. A plurality of ribs 221, adjacent ribs 221 form housing positioning grooves 222 engaged with the motor housing, every two housing positioning grooves are correspondingly provided with a pressing plate 23, and the pressing plate 23 is provided with a motor housing. The connecting seat corresponding to the step-shaped connecting seat positioning groove, the bottom of the connecting seat positioning groove corresponding to the installation hole is provided with a guide through hole 233, the outer end groove body 232 of the connecting seat positioning groove is fastened to the connecting part of the connecting seat and the motor housing The chamfer 132 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com