Wide and thick plate temperature monitoring method for grid exponential distribution

An exponential distribution, wide and thick plate technology, applied in the direction of temperature control, etc., can solve the problems of increasing the online calculation time of the rolling schedule calculation program and failing to meet the real-time requirements of wide and thick plate online control, so as to improve online computing efficiency and widen the temperature The effect of controlling precision and reducing online computing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

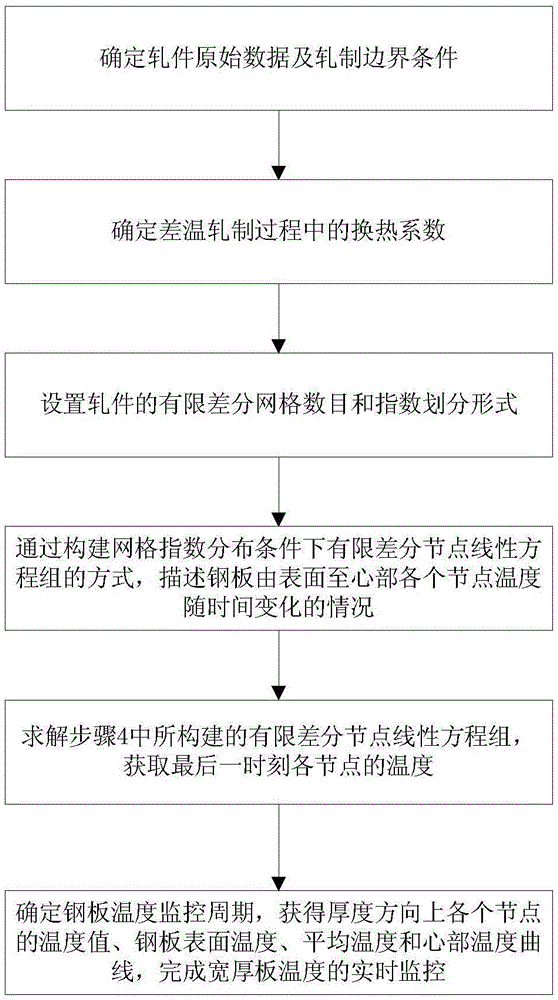

[0038] In the embodiment of the present invention, the temperature monitoring method for wide and thick plates with grid exponential distribution, the method flow chart is as follows figure 2 shown, including the following steps:

[0039] Step 1. Determine the raw data of the rolled piece and the rolling boundary conditions; the determination of the raw data of the rolled piece and the rolling boundary conditions, wherein the raw data of the rolled piece includes: the thickness of the rolled piece, width, length, reduction quantity, steel type and chemical composition, the rolling boundary conditions mentioned include: ambient temperature, cooling water temperature and roll temperature;

[0040] In the embodiment of the present invention, the original data of the rolled piece is determined: the thickness of the rolled piece is 300mm, the width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com