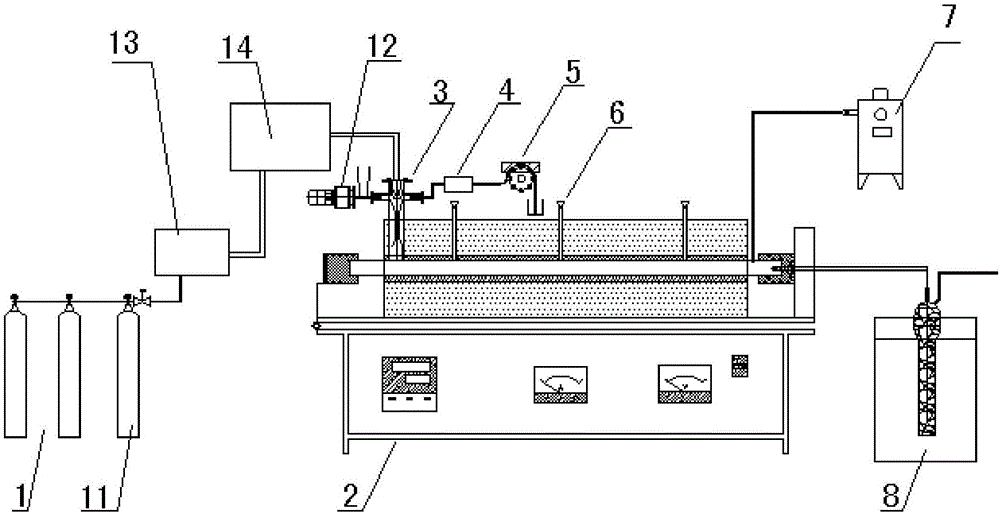

Device for interactive reaction between heavy metals and particulate matter and reaction method

A technology for heavy metals and particulate matter, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve problems such as lack of in-depth knowledge and understanding, and achieve the effects of convenient control, improved results, and prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Implementation example 1: The furnace temperature of three different temperature sections is uniformly set to 400°C, the gas flow rate of the flue gas in the flue gas mixing system is set to 3.14L / min, and only the heavy metal atmosphere is introduced, respectively in the three furnace sections Put in the powdered activated carbon contained in the corundum ark, and after ten minutes, take out the activated carbon in the three furnace sections, and separate them in a sampling port, and use the activated carbon to adsorb heavy metals for the same period of time, and then analyze the content of heavy metals.

[0026] It was found that the content of heavy metals in activated carbon is almost the same, such as Cu, the contents of Cu in the three samples are 30.08mg / Kg, 30.06mg / Kg, and 30.12mg / Kg respectively, so it is determined that the heavy metal atmosphere in the furnace is uniform of. And in the same sampling port, the Cu content of activated carbon in different time p...

Embodiment 2

[0027] Implementation Example 2: The furnace temperature of the three different temperature sections is uniformly set to 400°C, the gas flow rate of the flue gas in the flue gas mixing system is set to 3.14L / min, and only fine particles are fed through the screw feeder, respectively. At the time of 10min and 20min, the same time sampling was carried out at the three sampling ports.

[0028] It was found that the masses of the collected fine particles at 10 minutes were: 21.22mg, 21.23mg, 21.19mg. The masses at 20 minutes are: 21.31mg, 21.26mg, 21.23mg. The results show that the fine particles are stable and uniform in the furnace.

Embodiment 3

[0029] Implementation example 3: The furnace temperature of three different temperature sections is uniformly set to 400°C, and the atmosphere flow rate of the flue gas in the flue gas mixing system is set to 3.14L / min, and the heavy metal atmosphere and fine particles are respectively introduced through the flue The sampler takes samples at the sampling ports of the three furnace sections respectively, and detects the heavy metal content of the same amount of samples taken.

[0030] It was found that the content of heavy metals in samples with the same content is almost the same, such as Cu, the content of Cu in the three sampling ports is 20.30mg / Kg, 20.28mg / Kg, and 20.30mg / Kg respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com