An aqueous adhesive used for a sulfur cathode and applications thereof

A technology of water-based binder and sulfur positive electrode, which is applied to the sulfur positive electrode of lithium-sulfur secondary battery. , the adhesive is toxic and other problems, to achieve the effect of alleviating the volume change of the positive electrode, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, guar gum is used as the water-based binder for the sulfur cathode.

[0035] Sulfur-based composite material, guar gum, and graphene are uniformly dispersed in water at a mass ratio of 7:1.5:0.5, then coated on carbon-coated aluminum foil, dried, and pressed into sheets to obtain the positive electrode of a secondary lithium-sulfur battery; wherein the sulfur The matrix composite material is obtained by mixing elemental sulfur and polyacrylonitrile (weight-average molecular weight: 1 million) at a mass ratio of 4:1, then heating to 250°C under nitrogen protection and holding it for 16 hours.

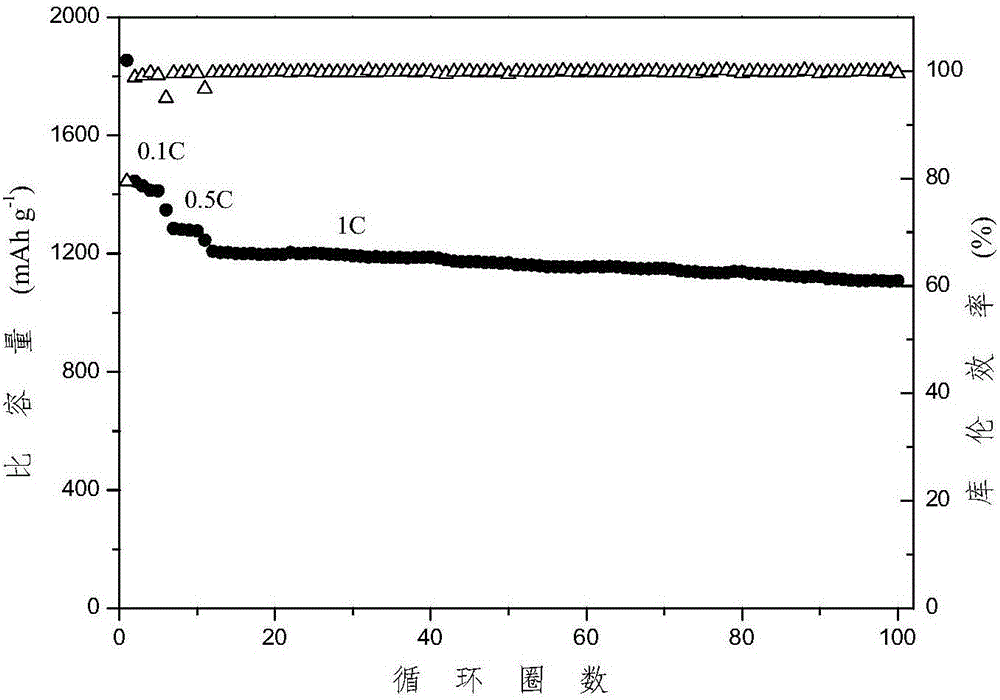

[0036] The positive electrode of the secondary lithium-sulfur battery prepared in this example and the negative electrode of metal lithium constitute a lithium-sulfur secondary battery. The specific capacity of the first discharge is 1970.9mAh / g, and the specific capacity is 1286mAh / g after 100 cycles of charge-discharge cycle test. g, such as figure 1 As shown...

Embodiment 2

[0038] In this embodiment, tara gum is used as the water-based binder for the sulfur cathode.

[0039] The sulfur-based composite material, tara gum, and conductive carbon fiber are uniformly dispersed in water at a mass ratio of 9:0.5:0.5, then coated on aluminum foil, dried and pressed into sheets to obtain the positive electrode of the secondary lithium-sulfur battery; the sulfur-based composite material It is obtained by mixing elemental sulfur and polyacrylonitrile (with a weight average molecular weight of 2 million) at a mass ratio of 16:1, then heating to 400°C under nitrogen protection and keeping it warm for 1 hour.

[0040] The positive electrode of the secondary lithium-sulfur battery prepared in this example and the negative electrode of metal lithium constitute a lithium-sulfur secondary battery. The specific capacity of the first discharge is 1796mAh / g, and the specific capacity after 100 cycles of charging and discharging is 1187mAh / g. ,Such as figure 2 shown. ...

Embodiment 3

[0042] In this embodiment, Kanaya gum is used as the water-based binder for the sulfur cathode.

[0043] Disperse the sulfur-based composite material, kana gum, and carbon nanotubes uniformly in water at a mass ratio of 8:1:1, and then coat them on the nickel foam, dry and press into sheets to obtain the positive electrode of the secondary lithium-sulfur battery; wherein The sulfur-based composite material is obtained by mixing elemental sulfur and polyacrylonitrile (with a weight-average molecular weight of 100,000) at a mass ratio of 8:1, then heating to 300°C under nitrogen protection and holding it for 8 hours.

[0044] The positive electrode of the secondary lithium-sulfur battery prepared in this example and the negative electrode of metal lithium constitute a lithium-sulfur secondary battery. The specific capacity of the first discharge is 1854mAh / g, and the specific capacity is 1108mAh / g after 100 cycles of charge-discharge cycle test. ,Such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com