Online gas collecting and exhausting device and method for nuclear power station fluid system non-condensable gas

A fluid system and exhaust device technology, applied in the field of nuclear power, can solve the problems of large discharge fluid, flow field cavitation, high discharge flow, etc., and achieve the effects of avoiding a large amount of discharge, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

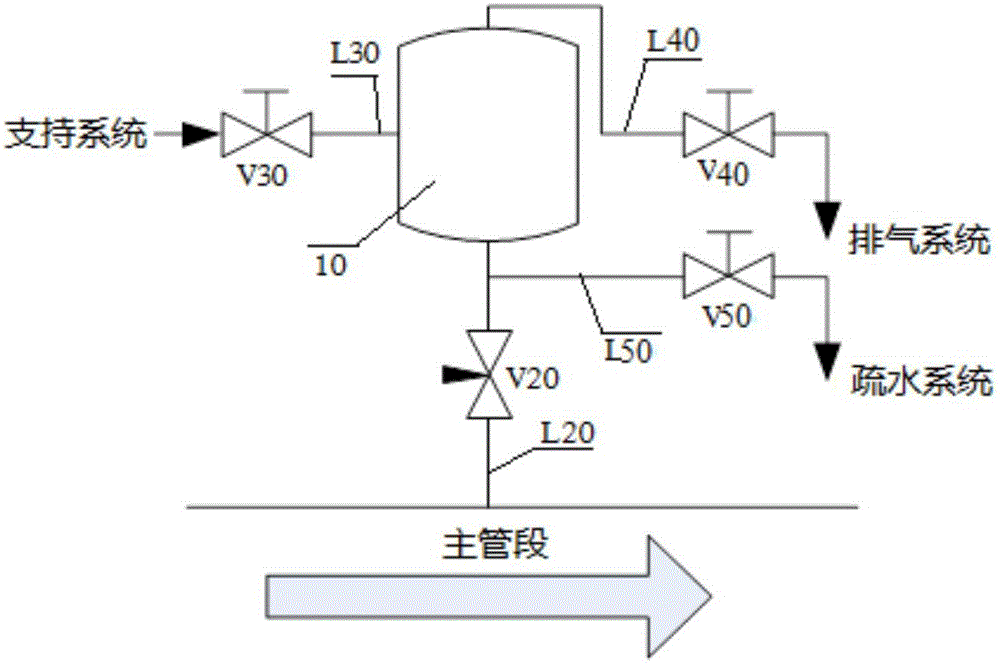

[0037] Please refer to figure 2 As shown, the noncondensable gas online gas collection and exhaust device of the nuclear power plant fluid system of the present invention includes: a gas collection tank 10, a gas collection pipeline L20 connected to the bottom of the gas collection tank 10, a gas collection valve V20, and a water injection valve connected to the gas collection tank 10 V30 and water injection pipeline L30, exhaust pipeline L40 and exhaust valve V40 connected to the top of the gas collection tank 10, and drain pipeline L50 and drain valve V50 connected to the gas collection pipeline L20. The local high point of the segment fluid system is connected, and the drain line L50 is connected to the gas collection line L20 between the gas collection tank 10 and the gas collection valve V20.

[0038] The gas collection valve V20 is installed vertically on the gas collection pipeline L20 and above the main section of the nuclear power plant, and the gas collection tank 1...

Embodiment 2

[0046] For the exhaust work of the high temperature and high pressure fluid system in nuclear power plants, please refer to figure 2 As shown, its structure is basically the same as the structure of Embodiment 1 of the non-condensable gas online gas collection and exhaust device of the nuclear power plant fluid system of the present invention, the difference is only that the support system (not shown), the hydrophobic exhaust system (not shown) Shown) and the cooling device of the air collecting tank 10.

[0047] According to Embodiment 2 of the present invention, for the high-temperature and high-pressure system, in the exhaust stage, it is first necessary to properly cool down the gas collecting tank 10, and the cooling can be through natural heat dissipation, or a forced convection cooling device can be added externally; secondly, it needs to be upstream of the water injection valve V30 Set pressurization measures (such as plunger pumps) to increase the injected fluid to t...

Embodiment 3

[0051] For the special environment where the radioactive intensity is high in nuclear power plants, or the installation position of the main pipe section is high, and it is difficult for operators to approach, the structure of Embodiment 3 of the present invention is the same as that of Embodiment 1 of the noncondensable gas online gas collection and exhaust device for the fluid system of a nuclear power plant of the present invention. The structures are basically the same, the only difference is that the water injection valve V30, the exhaust valve V40 and the steam trap V50 are installed in relatively far away from the gas collection tank 10 and are easily accessible. The gas collecting valve V20 is preferably a solenoid valve, and may also be an electric valve or a pneumatic valve, which is convenient for the operator to operate safely. The gas collection process and exhaust process in Embodiment 3 of the present invention are consistent with the gas collection process and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com