Wireless networked temperature and humidity inspection system and calibration method

A technology of inspection system and calibration method, applied in signal transmission systems, electrical signal transmission systems, instruments, etc., can solve the problems of signal error, difficulty in construction of large systems, and large costs, so as to reduce construction costs and construction difficulties. Troubleshooting Difficulty, Avoiding the Effects of Monitoring and Calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below in conjunction with the drawings.

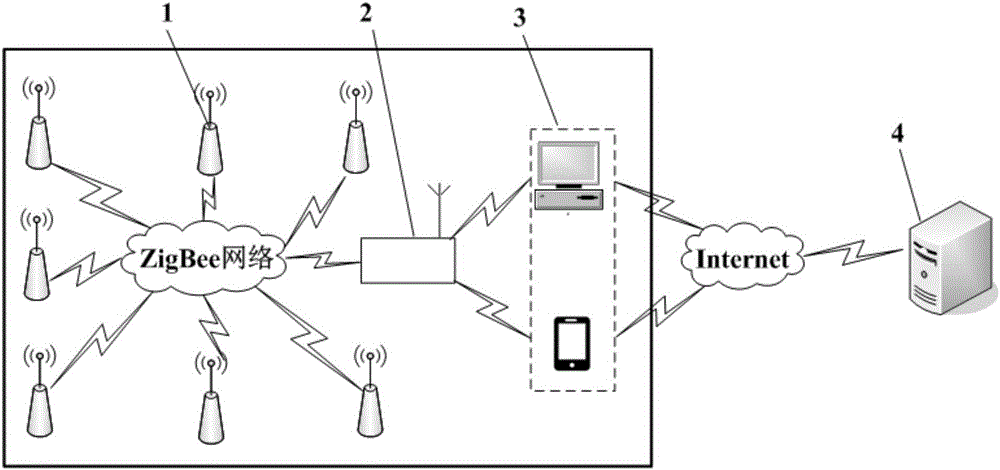

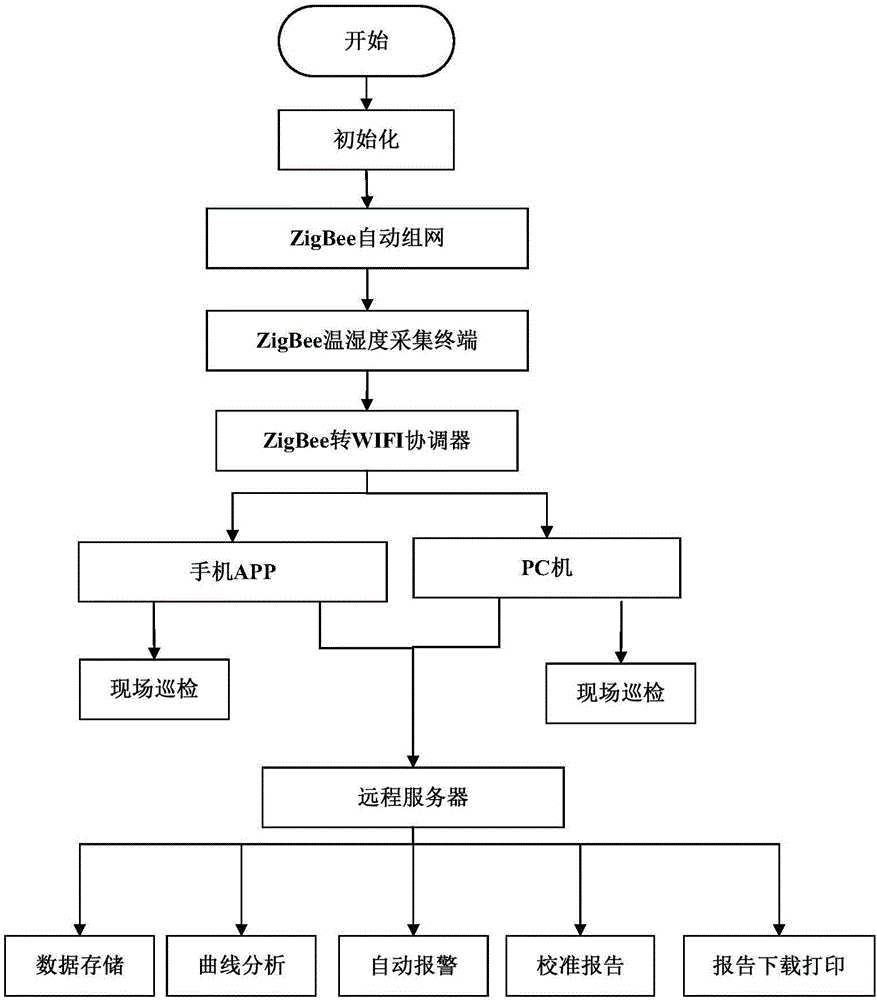

[0020] Combine figure 1 Description: In the present invention, multiple ZigBee temperature and humidity collection terminals 1 are installed at designated temperature and humidity detection points on the work site to measure the temperature and humidity data of each temperature and humidity detection point; ZigBee to WIFI coordinator 2 and each ZigBee temperature and humidity collection terminal 1 Communication, the ZigBee network is automatically formed; the mobile phone or PC 3 communicates with the ZigBee to WIFI coordinator 2 wirelessly, and the temperature and humidity changes at each temperature and humidity detection point are monitored on the spot; the remote server receives the data uploaded from the mobile phone or the PC 3 through the Internet network to achieve Remote inspection and remote calibration of temperature and humidity.

[0021] The ZigBee temperature and hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com