Method for automatically detecting key points for casing collars of steel pipes

A casing coupling and automatic detection technology, applied in the field of quality engineering, can solve the problems of outflow, loss, oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

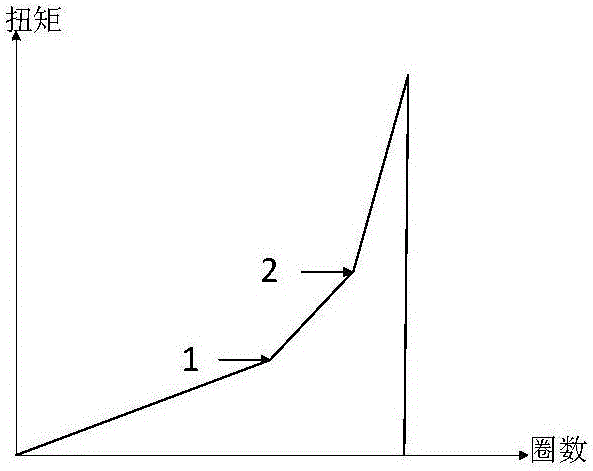

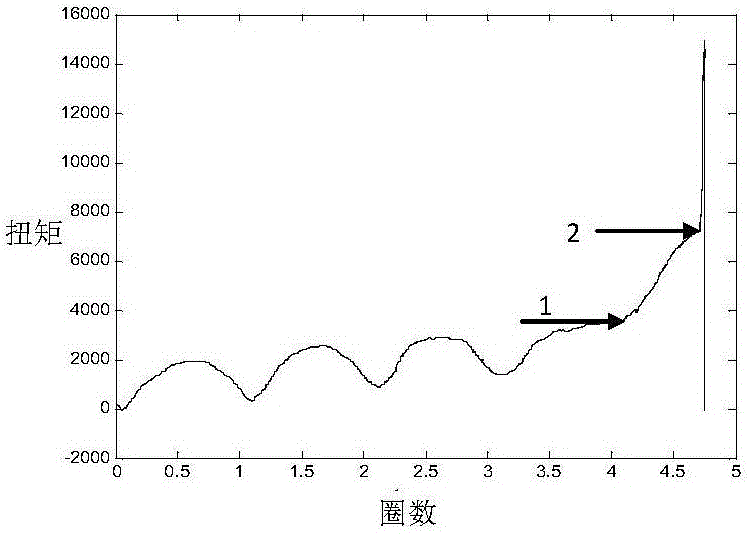

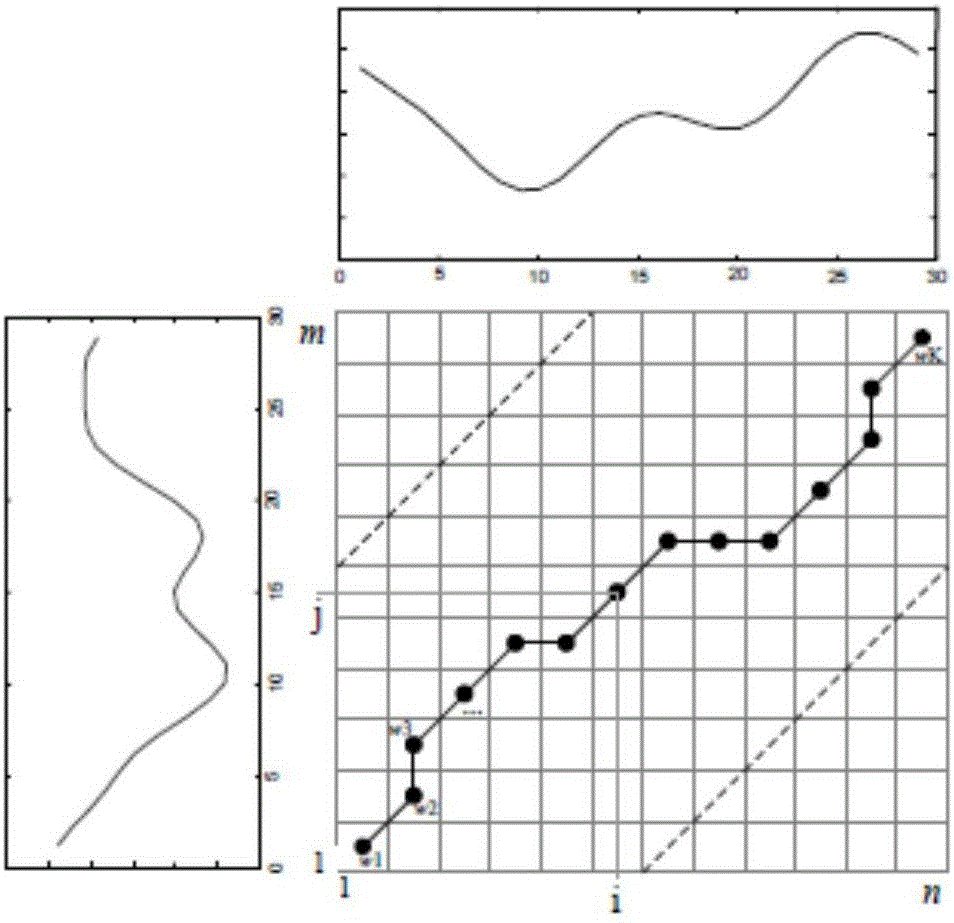

[0065] The invention provides a key point detection method for casing collar connection, establishes a two-stage model framework, and proposes an advanced statistical method using positive and negative sequences to detect two key explainable change points. The method described is based on the torque signal of a casing collar connection with a sealing surface: first based on a dynamic time warping method to measure the similarity of the torque signal and an interpretable physical basis. Then, in the first stage, all potential change points in the torque signal are detected based on the statistical test of F-maximum and the two-phase regression model. In the second stage, two more likely key change points are selected through the screening of reverse order change points based on physical constraints. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com