A kind of manufacturing method of artificial coal core standard test piece

A technology of standard test pieces and production methods, which is applied in the preparation, sampling, and instrumentation of test samples. It can solve the problems of cumbersome operation, high failure rate, and large size, and achieve good repeatability, make up for poor repeatability, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] A kind of manufacture method of artificial coal core standard test piece provided by the invention, described method comprises the following steps:

[0034] 1) Select a coal sample and prepare coal particles of the desired particle size;

[0035] 2) Select formation water or standard brine as the binder;

[0036] 3) mixing the coal particles in step 1) and the binder in step 2) uniformly in a certain proportion;

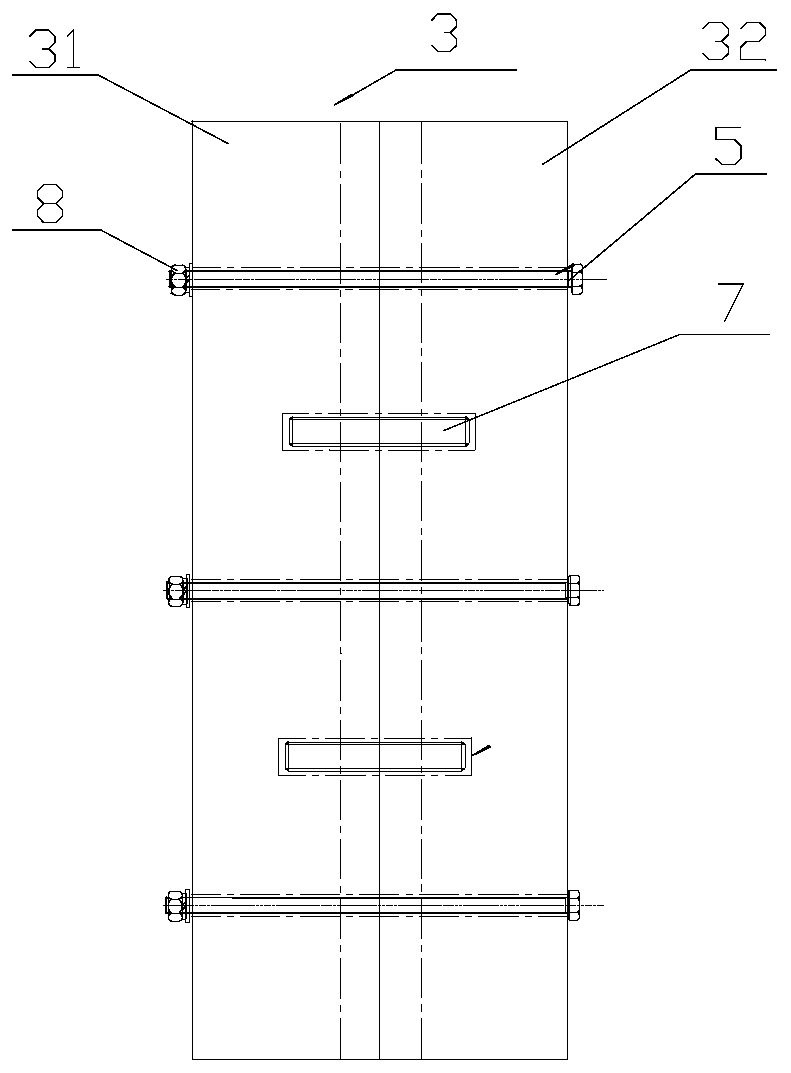

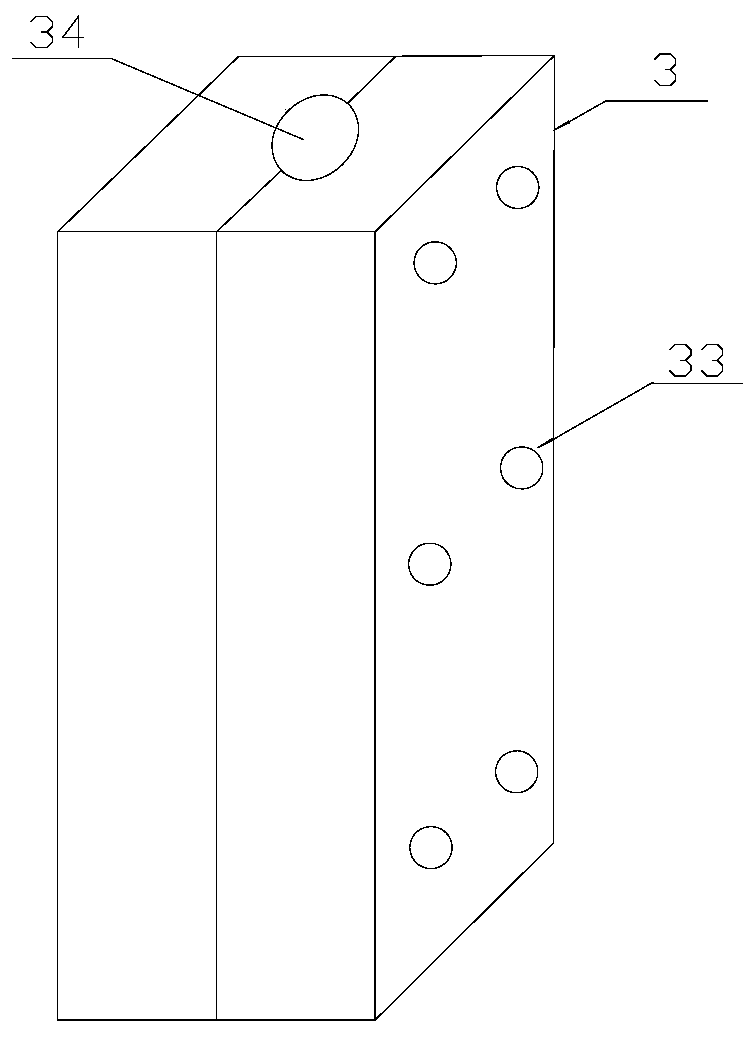

[0037] 4) put the homogeneously mixed sample in step 3) into the coal core mold several times, and compact each time the homogeneously mixed sample is added;

[0038] 5) After completing step 4), pressurize at a constant speed to the preset pressure and keep the pressure constant;

[0039] 6) After the preset pressure is mainta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com