A method for measuring the size of transition section of gas turbine combustor

A gas turbine, size detection technology, applied in the direction of combustion method, combustion chamber, continuous combustion chamber, etc., can solve the problems of narrowing the processing size tolerance range of parts in the transition section of the combustion chamber, design reference deviation, affecting the characteristic size of parts, etc., and achieve the detection results Intuitive, improve detection efficiency, facilitate production and processing size adjustment and fitter repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

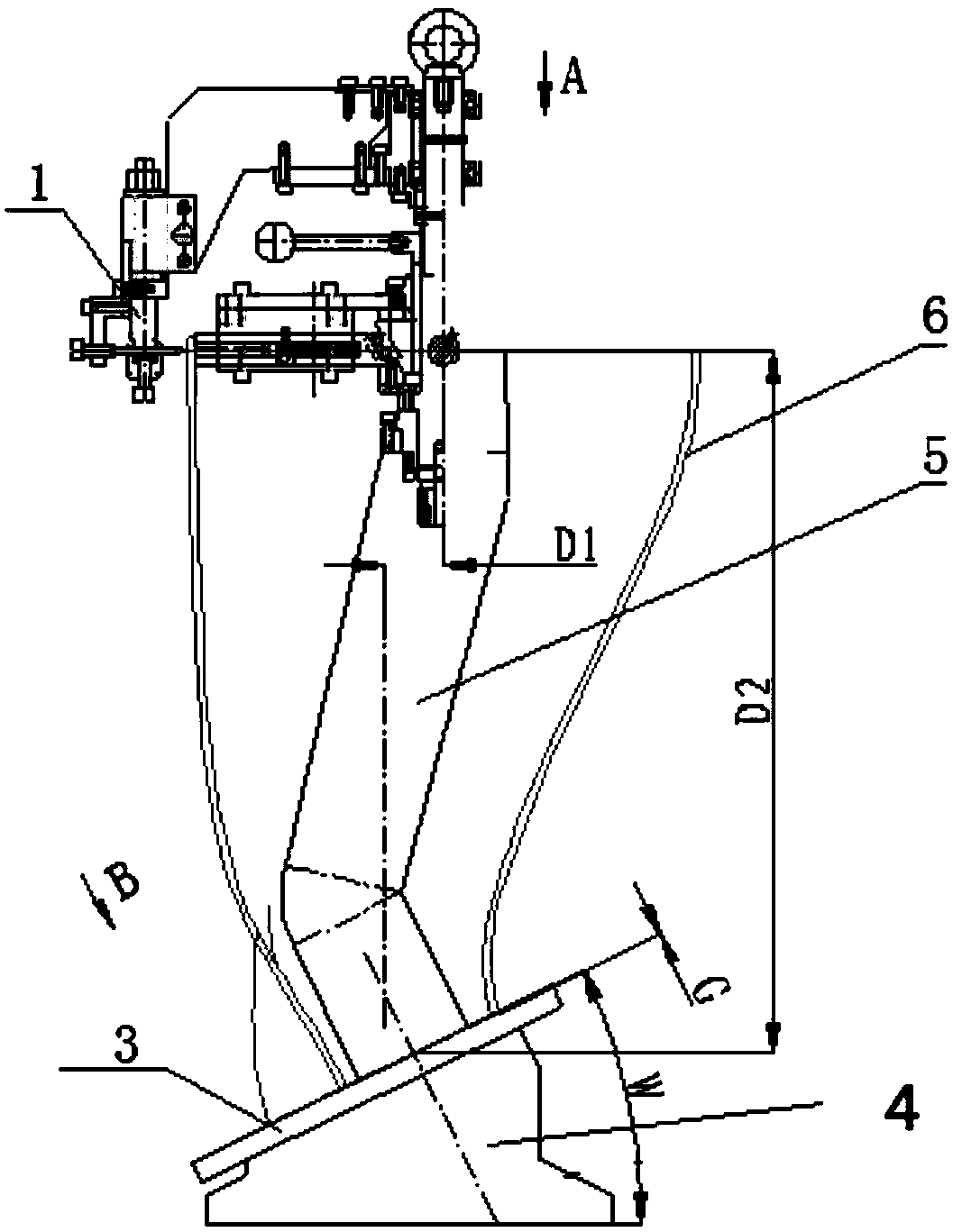

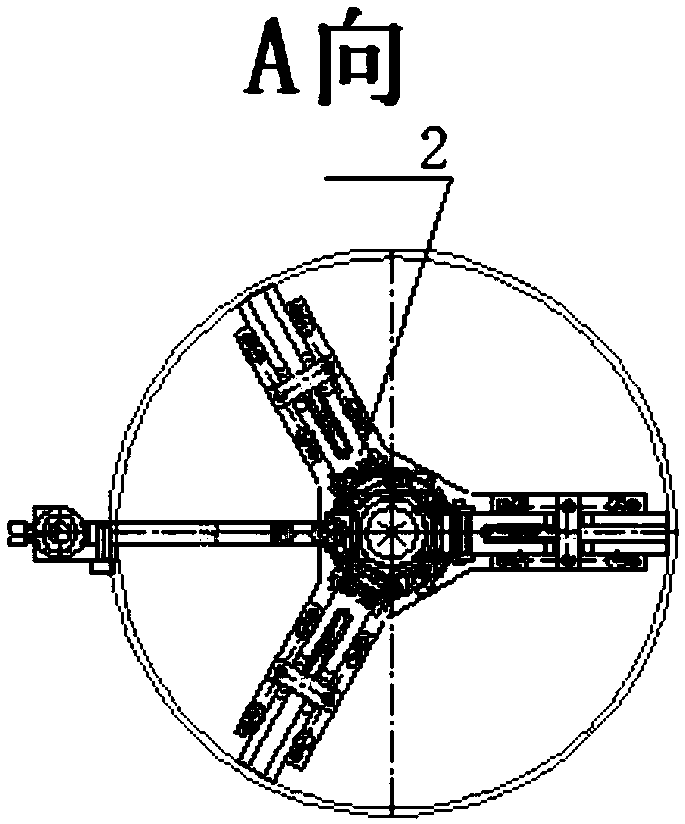

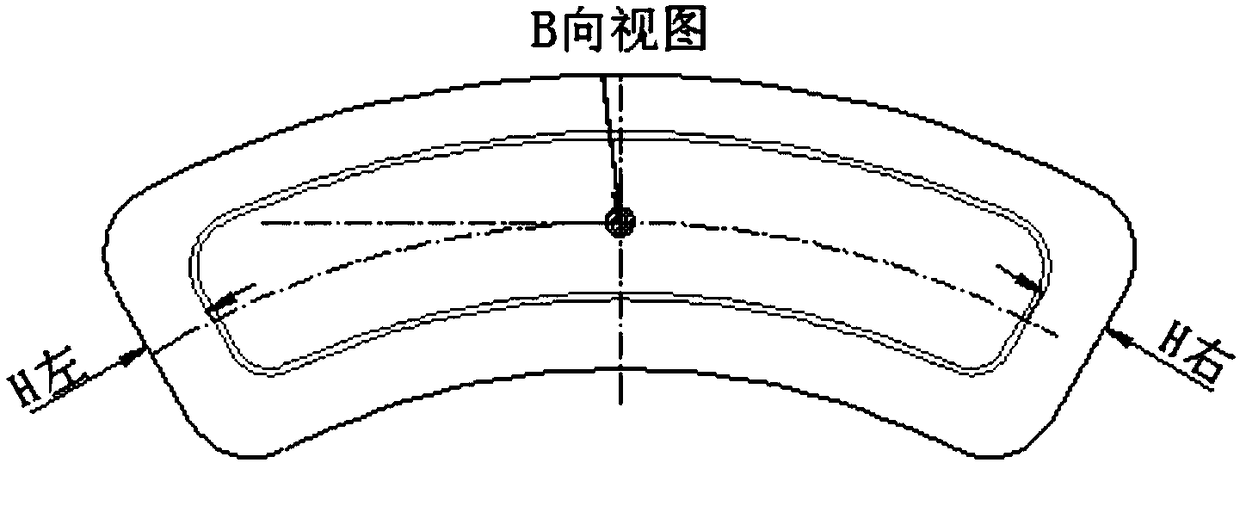

[0018] The invention provides a method for detecting the size of the transition section of the gas turbine combustor, which is characterized in that: the method for detecting the size of the transition section of the gas turbine combustor, the function of the parts of the transition section of the gas turbine combustor in the combustion chamber components It is the transfer transition, which transfers the high-temperature gas from the air inlet, that is, the round mouth end, to the gas outlet end through the profile transfer, to achieve the purpose of rectification; in order to meet the assembly requirements of the transition section of the combustion chamber, the processing of the transition section of the combustion chamber In the process, it is enough to ensure its relative assembly size requirements in the lower-level components. By simulating the assembly state of the transition section of the combustion chamber, a comprehensive measuring tool is designed and manufactured ...

Embodiment 2

[0024] The invention provides a method for detecting the size of the transition section of the gas turbine combustor, which is characterized in that: the method for detecting the size of the transition section of the gas turbine combustor, the function of the parts of the transition section of the gas turbine combustor in the combustion chamber components It is the transfer transition, which transfers the high-temperature gas from the air inlet, that is, the round mouth end, to the gas outlet end through the profile transfer, to achieve the purpose of rectification; in order to meet the assembly requirements of the transition section of the combustion chamber, the processing of the transition section of the combustion chamber In the process, it is enough to ensure its relative assembly size requirements in the lower-level components. By simulating the assembly state of the transition section of the combustion chamber, a comprehensive measuring tool is designed and manufactured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com