Method and apparatus for measuring parallelism of germanium window plate

A parallelism and window technology, applied in the field of optical detection, can solve the problems of inaccurate parallelism, inability to reflect the influence of germanium window height on parallelism, and expensive equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

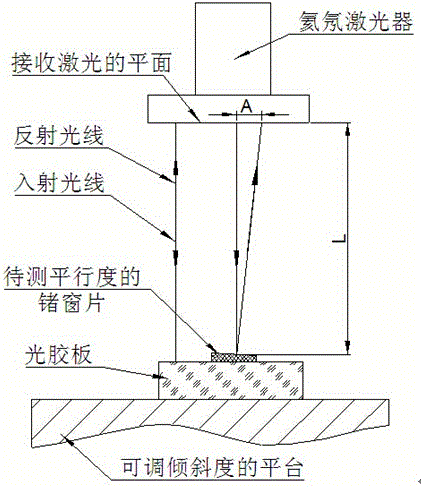

[0007] Glue the lower surface of the germanium window to be tested on a fused silica photoplastic plate with a flatness of 100nm so that the lower surface of the germanium window is completely parallel to the surface of the photoplastic plate, and adjust the inclination of the platform to make the surface of the photoplastic plate and the laser Vertical, that is, the reference plane receiving the reflected laser interferes with the surface of the photoresist to form interference fringes S1. At this time, the reference plane receiving the reflected laser also interferes with the upper surface of the germanium window to form interference fringes S2. After image comparison analysis S1 and S2 to obtain the maximum offset A, the distance between the reference plane receiving the reflected laser and the germanium window is L, according to the principle of optical reflection, the parallelism between the surface of the optical plastic plate and the upper surface of the germanium window ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com