Method for achieving harmless disposal of garbage fly ash by means of rotary kiln technology

A garbage fly ash, rotary kiln technology, applied in the direction of combustion method, combustion technology mitigation, incinerator, etc., to achieve the effect of good environmental conditions, easy concentration and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

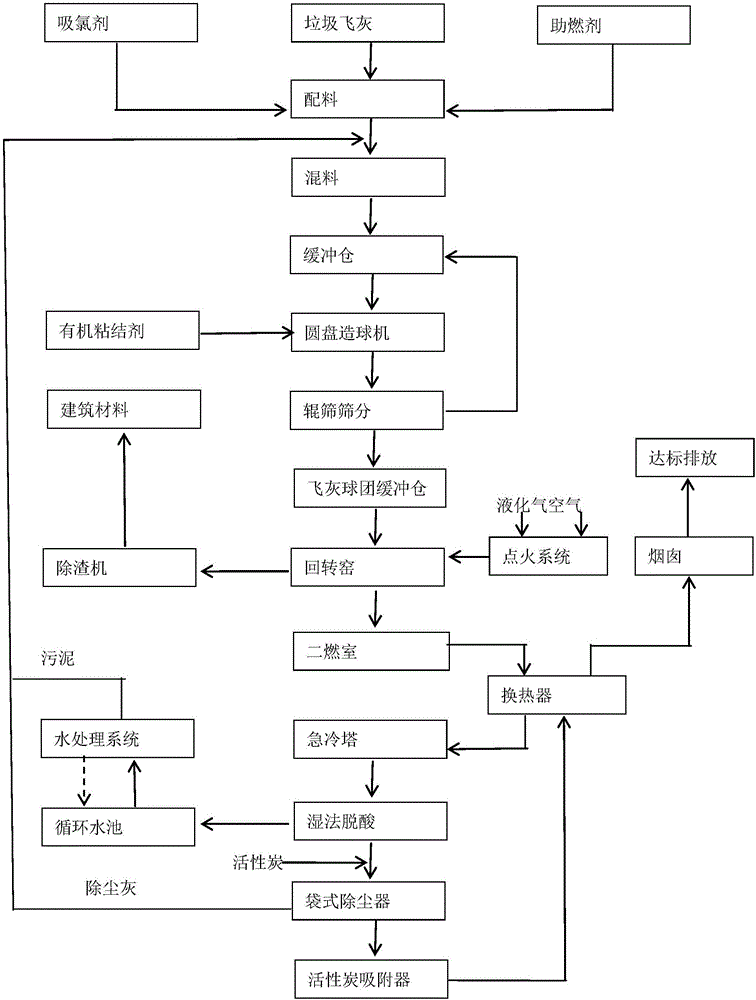

[0024] The following is a detailed description of the method of using the rotary kiln technology to dispose of garbage fly ash harmlessly:

[0025] as attached figure 1 Shown: mix garbage fly ash into chlorine absorbent and combustion accelerant in a certain proportion;

[0026] Put the prepared materials into the mixer and mix them evenly;

[0027] Put the mixed material into the buffer bin and evenly enter the disc pelletizer, and add organic binder to pelletize at the same time, the pellet size is controlled at 6-12mm;

[0028] The finished fly ash pellets are sent to the rotary kiln head after being sieved by a roller screen, and the garbage fly ash pellets ignited by the ignition system are roasted in the rotary kiln and move to the kiln tail during the rotation of the rotary kiln. When reaching the end of the kiln, the combustion accelerant in the garbage fly ash pellets has been completely burned, and the residues of harmful substances such as dioxin in the garbage fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com