Casing oil recovery device and process

A technology of oil recovery and casing, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of no casing oil recovery technology and application device, unfavorable refined management, and less recovered liquid. , to achieve the effects of scientific management, prevention of oil stealing, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

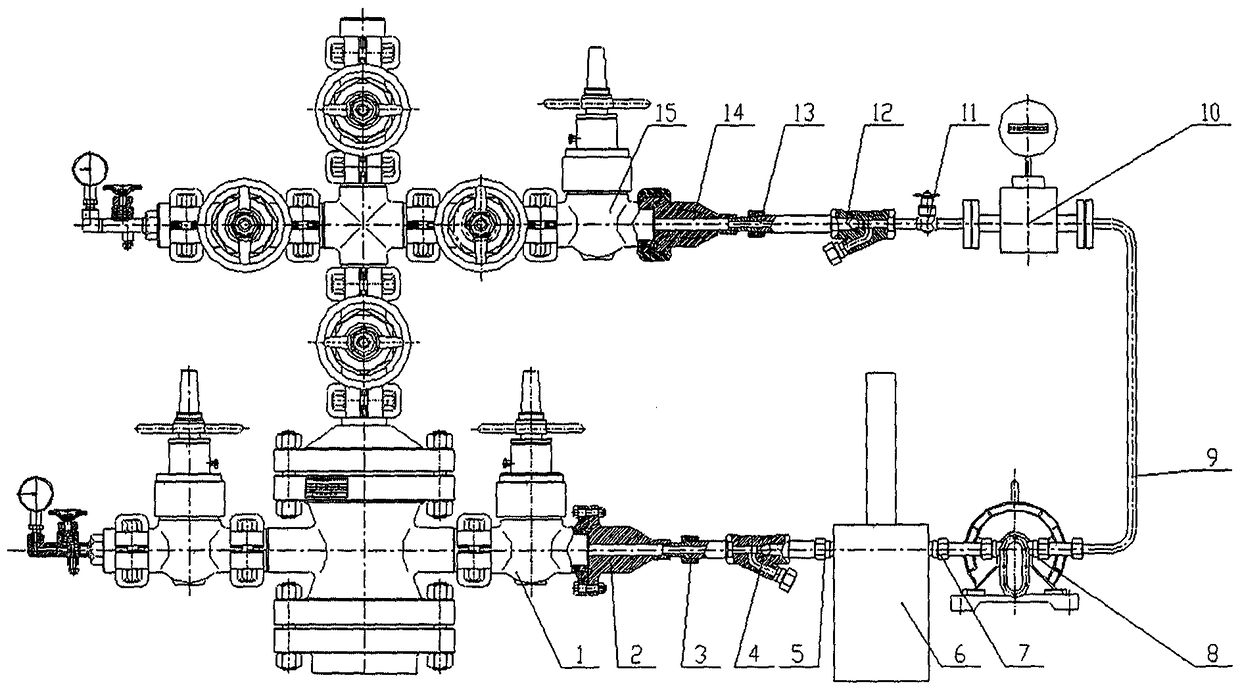

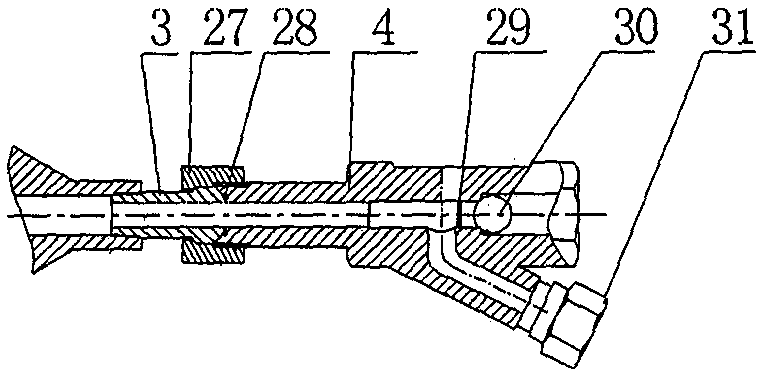

[0029] A casing oil recovery device, comprising a liquid inlet valve 1 connected to the valve of the oil production well, characterized in that: the liquid inlet valve 1 is connected to the short connection A2 through a clamp or a flange, and the oil valve is connected One end of A3 is connected with the connecting short-circuit A2 screw, and the other end of connecting oil nonel A3 is in contact with filter check valve A4. It can be rotated arbitrarily within the range of ±30°, and is threadedly connected with the filter check valve A4 through the nut 27; the liquid inlet 5 of the data collector 6 is connected with the filter check valve A4, and the liquid outlet 7 is connected with the recovery pump 8 connection, the recovery pump 8 is connected to the filter check valve B12 through the pipeline 9, the flow meter 10 and the stop valve 11 are installed on the pipeline 9, the end of the connection oil nonel B13 is connected with the short connection B14 screw, and the oil nonel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com