Foundation pile self-balance detection device with internal grouting function

A detection device and self-balancing technology, which are used in infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as potential safety hazards, uneven stress on foundation piles, and inability to properly relieve pressure, and achieve reliable test results. The effect of accurate settlement and complete integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

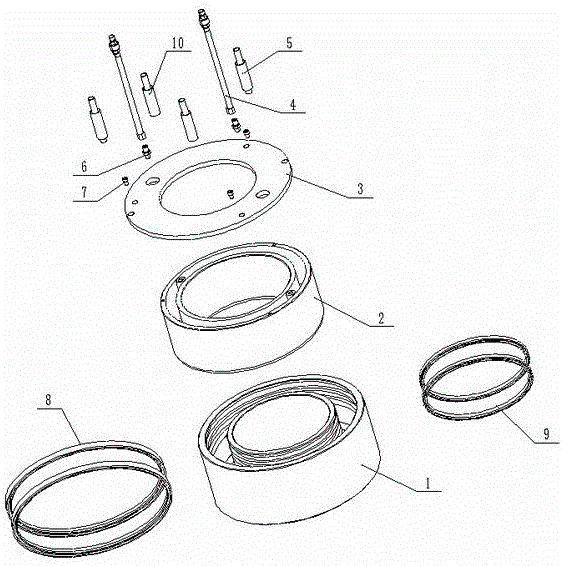

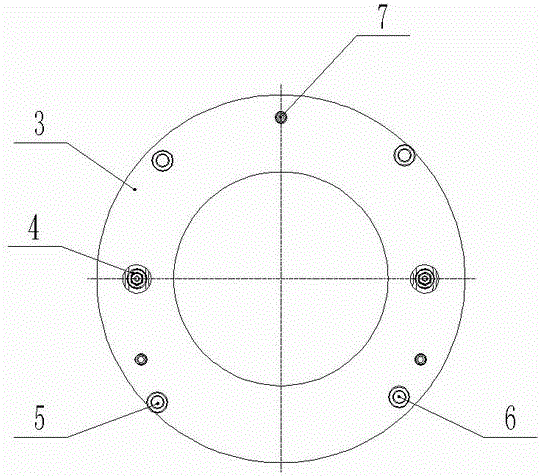

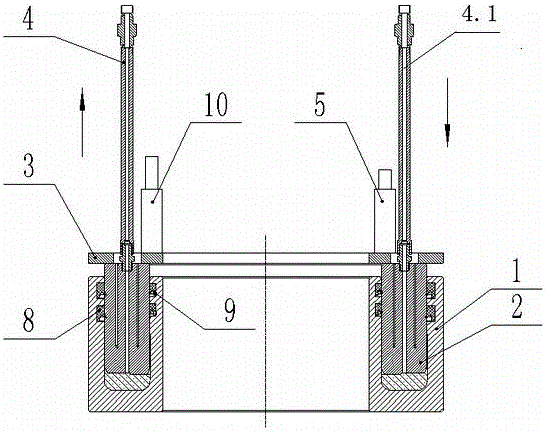

[0025] Attached below figure 1 , 2 3, the device of the present invention is described in detail:

[0026] A self-balancing detection device for foundation piles with internal grouting, which includes an integral annular cylinder 1, an integral annular piston 2, an annular panel 3, an upper displacement pipe 5, a lower displacement pipe 10, a liquid inlet pipe 4.1, a liquid return pipe 4, and a grease nozzle. 6;

[0027] It is characterized in that: the device is installed in the middle section of the foundation pile, the annular panel 3 is welded with the reinforcement cage of the upper section of the foundation pile, the bottom of the annular integral cylinder 1 is welded with the reinforcement cage of the lower section, and the upper displacement tube 5 is welded on the annular panel 3. And through the protective pipe directly to the surface;

[0028] The lower displacement pipe 10 is welded on the end surface of the outer wall of the annular integral cylinder block 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com