An anchorage structure for steel pipe pile bottom in bare rock geological force

A steel pipe pile and geology technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of small actual pile end bearing capacity, pile bottom concrete damage, difficult control of spacing and height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

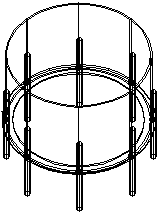

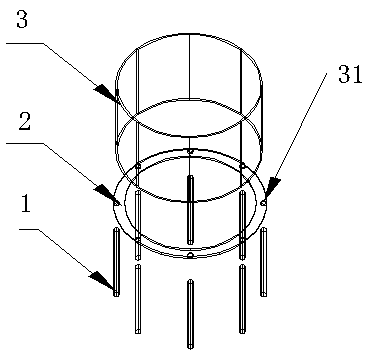

[0033] See figure 1 , 2 , The present invention discloses an anchoring structure at the bottom of a steel pipe pile under bare rock geology, which includes the following steps:

[0034] A. Processing supporting steel bars 1;

[0035] B. Processing 2 pieces of annular support steel plate;

[0036] C. Prepare 3 steel pipe pile protection tube or one steel pipe pile;

[0037] D. Weld the annular support steel plate 2 with the steel pipe pile protective tube 3 or the bottom of the steel pipe pile into a whole, and set the steel pipe pile into the steel pipe pile protective tube 3 and set it in the middle position of the annular support steel plate 2, or the steel pipe pile The bottom is set at the middle position of the annular support steel plate 2;

[0038] E. Weld the supporting steel bars 1 in turn around the annular supporting steel plate 2;

[0039] F. After the hole formation of the bedrock is completed, the steel pipe pile is hoisted into the hole, and underwater concrete is poured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com