A system and method for controlling a pelletizing disc

A control system and a ball-making disc technology, applied in the field of metallurgical industry automation, can solve the problems of signal jitter, distortion, complicated workload, etc., and achieve the effect of reducing workload, easy operation, and improving the quality of green balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

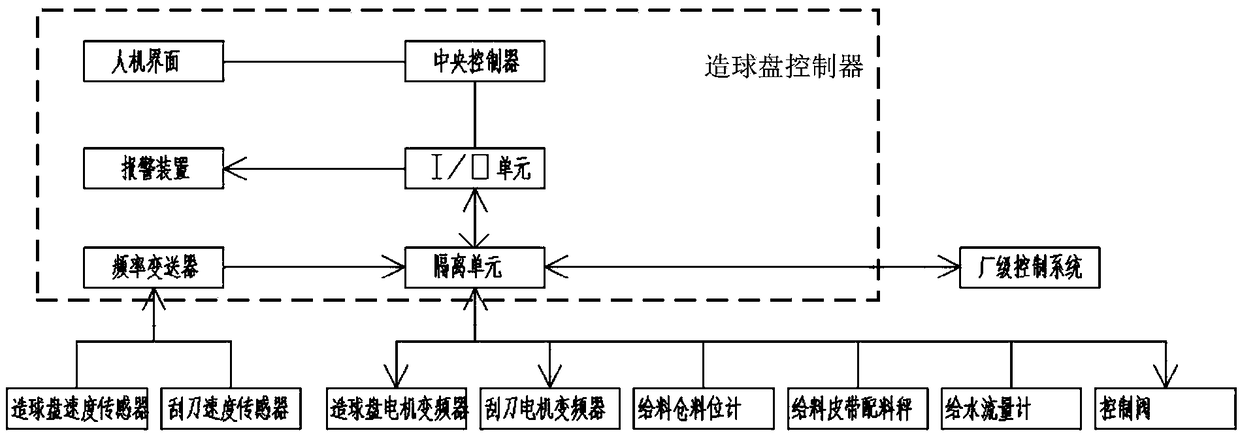

[0032] like figure 1 As shown, a kind of pelletizing disc control system in this embodiment includes:

[0033] Pelletizing disc controller, feeding bin material level meter, feeding belt batching scale, feed water flow meter, control valve, pelletizing disc speed sensor and scraper speed sensor;

[0034] The pelletizing disk controller includes: a device shell, an isolation unit, an I / O unit, a frequency transmitter, a central controller, an alarm device, and a man-machine interface; the isolation unit, the I / O unit, and a frequency transmitter 1. The central controller is set in the device shell, and the man-machine interface and alarm device are set on the front surface of the device shell.

[0035] The output end of the feed bin material level gauge, the output end of the feeding belt batching scale, the output end of the feed water flowmeter an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com