Method for producing Shanxi mature vinegar powder through cooperation of microcapsule molecular embedding and spray drying

A technology of mature vinegar and microcapsules, which is applied in the field of vinegar processing, to achieve the effect of reducing the particle size of the material, solving the problem of easy moisture absorption and caking, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

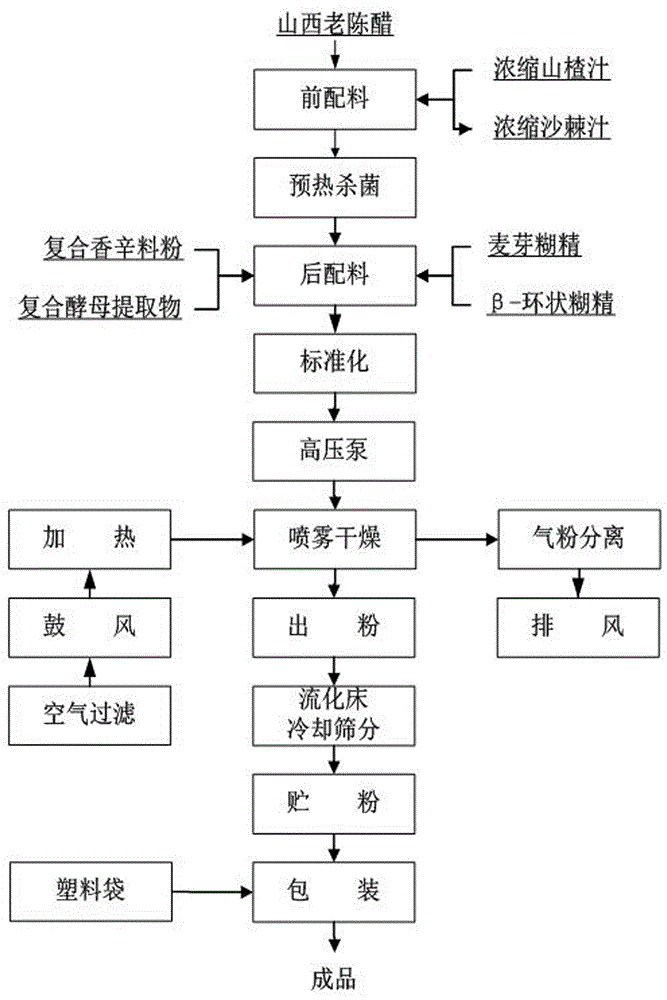

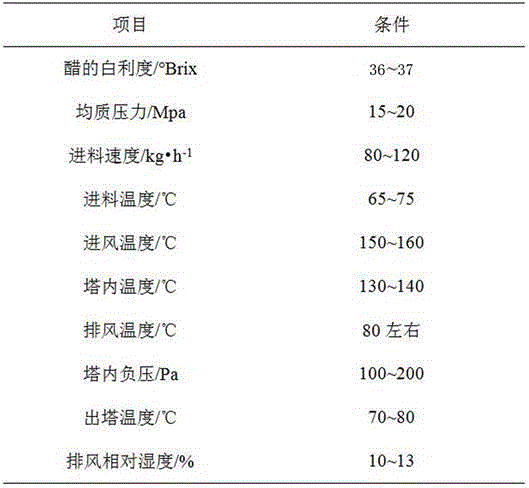

[0042] A method for producing Shanxi aged vinegar powder by microcapsule molecular embedding and cooperative spray drying, comprising the following steps:

[0043] (1), the former ingredients

[0044] Mix Shanxi mature vinegar, concentrated hawthorn juice, and concentrated seabuckthorn juice as a batching solution; wherein, Shanxi mature vinegar has a Brix of 14-16°Brix, a total acid of 6-7g / 100mL, and a mass percentage of 85.0% of the batching solution; concentrated The Brix of hawthorn juice is 70~75°Brix, the total acid is 5.0~6.0g / 100mL, and the mass percentage is 10.0% of the ingredient liquid; the Brix of concentrated seabuckthorn juice is 60~65°Brix, and the total acid is 10~ 12g / 100mL, the mass percentage is 5.0% of the batching solution; after complete mixing, the acidity of the batching solution is 6.15~7.00g / 100mL, and the Brix of the batching solution is 22.5~25.3°Brix.

[0045] (2), preheating sterilization

[0046] The UHT instantaneous sterilization method is ...

Embodiment 2

[0063] A method for producing Shanxi aged vinegar powder by microcapsule molecular embedding and cooperative spray drying, comprising the following steps:

[0064] (1), the former ingredients

[0065] Mix Shanxi mature vinegar, concentrated hawthorn juice, and concentrated seabuckthorn juice as a batching liquid; wherein, Shanxi mature vinegar has a Brix of 14-16°Brix, a total acid of 6-7g / 100mL, and a mass percentage of 82.75% of the batching liquid; concentrated The Brix of hawthorn juice is 70~75°Brix, the total acid is 5.0~6.0g / 100mL, and the mass percentage is 11.5% of the ingredient liquid; the Brix of concentrated seabuckthorn juice is 60~65°Brix, and the total acid is 10~ 12g / 100mL, the mass percentage is 5.75% of the batching solution; after complete mixing, the acidity of the batching solution is 6.15~7.00g / 100mL, and the Brix of the batching solution is 22.5~25.3°Brix.

[0066] (2), preheating sterilization

[0067] The UHT instantaneous sterilization method is ad...

Embodiment 3

[0084] A method for producing Shanxi aged vinegar powder by microcapsule molecular embedding and cooperative spray drying, comprising the following steps:

[0085] (1), the former ingredients

[0086] Mix Shanxi mature vinegar, concentrated hawthorn juice, and concentrated seabuckthorn juice as a batching liquid; wherein, Shanxi mature vinegar has a Brix of 14-16°Brix, a total acid of 6-7g / 100mL, and a mass percentage of 84.0% of the batching liquid; concentrated The Brix of hawthorn juice is 70~75°Brix, the total acid is 5.0~6.0g / 100mL, and the mass percentage is 10.5% of the ingredient liquid; the Brix of concentrated seabuckthorn juice is 60~65°Brix, and the total acid is 10~ 12g / 100mL, the mass percentage is 5.5% of the batching solution; after complete mixing, the acidity of the batching solution is 6.15~7.00g / 100mL, and the Brix of the batching solution is 22.5~25.3°Brix.

[0087] (2), preheating sterilization

[0088] The UHT instantaneous sterilization method is adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com