Hydrophobic coating for power transformation equipment and preparation method thereof

A technology for hydrophobic coatings and power transformation equipment, which is applied in the direction of anti-fouling/underwater coatings, anti-corrosion coatings, coatings, etc., which can solve the problems of low economic value, insufficient mechanical strength, and high production costs, and achieve improved waterproof and anti-fouling Good performance, good acid and alkali resistance, low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

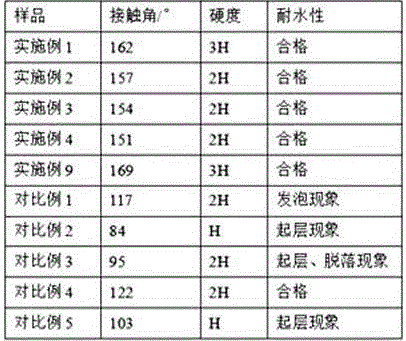

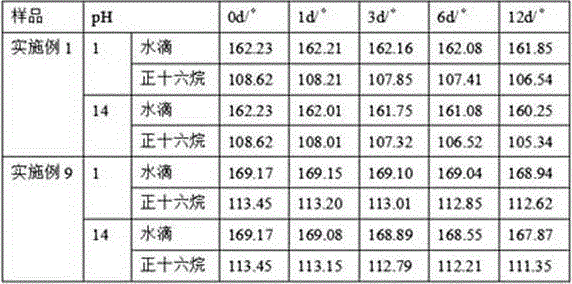

Examples

Embodiment 1

[0027] Example 1: A hydrophobic coating for electrical substation equipment, prepared from the following raw materials in parts by weight: 60 parts of methyltriethoxysilane, 28 parts of phosphate-modified acrylic emulsion, 15 parts of solvent, and 9 parts of filler , 5 parts of dispersant, 9 parts of film-forming agent.

[0028] Wherein, the solvent is hydrochloric acid solution;

[0029] The filler is a molecular sieve, and SiO in the molecular sieve 2 / Al 2 o 3 The molar ratio is 70.

[0030] The dispersant is a mixture of fatty alcohol polyoxyethylene ether and alkylsulfonate, and the weight ratio of fatty alcohol polyoxyethylene ether and alkylsulfonate is 2:1.

[0031] The film-forming agent is sodium polyacrylate.

[0032] A preparation method for a hydrophobic coating for electrical substation equipment, comprising the following steps:

[0033]Step S1: Weigh 60 parts by weight of methyltriethoxysilane, add dropwise a hydrochloric acid solution with a molar concent...

Embodiment 2

[0041] Example 2: A hydrophobic coating for power transformation equipment, prepared from the following raw materials in parts by weight: 55 parts of methyltriethoxysilane, 25 parts of phosphate-modified acrylic emulsion, 12 parts of solvent, and 8 parts of filler , 4 parts of dispersant, 8 parts of film-forming agent.

[0042] Wherein, the solvent is hydrochloric acid solution;

[0043] The filler is a molecular sieve, and SiO in the molecular sieve 2 / Al 2 o 3 The molar ratio is 50.

[0044] The dispersant is fatty alcohol polyoxyethylene ether sulfonate.

[0045] The film forming agent is polyvinyl alcohol.

[0046] A preparation method for a hydrophobic coating for electrical substation equipment, comprising the following steps:

[0047] Step S1: Weigh 55 parts by weight of methyltriethoxysilane, add dropwise a hydrochloric acid solution with a molar concentration of 0.02 mol / L to adjust the pH to 3.2, heat in an ultrasonic water bath for gelation reaction, and obtai...

Embodiment 3

[0053] Example 3: A hydrophobic coating for power transformation equipment, prepared from the following raw materials in parts by weight: 58 parts of methyltriethoxysilane, 30 parts of phosphate-modified acrylic emulsion, 15 parts of solvent, and 10 parts of filler , 6 parts of dispersant, 10 parts of film-forming agent.

[0054] Wherein, the solvent is an acetic acid solution; the filler is a molecular sieve, and SiO in the molecular sieve 2 / Al 2 o 3 The molar ratio is 30; the dispersant is fatty alcohol polyoxyethylene ether; the film-forming agent is sodium polyacrylate.

[0055] A preparation method for a hydrophobic coating for electrical substation equipment, comprising the following steps:

[0056] Step S1: Weigh 58 parts by weight of methyltriethoxysilane, add dropwise a hydrochloric acid solution with a molar concentration of 0.01 mol / L to adjust the pH to 3.6, heat in an ultrasonic water bath for gelation reaction, and obtain a sol;

[0057] Step S2: Add 6 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com