Wet-mixed thermal mortar doped with phosphorus slag and free of shrinkage and preparation method

A thermal insulation mortar, non-shrinkage technology, applied in the field of building materials, can solve problems such as the difficulty of supplying mortar to meet large-scale construction needs, the poor quality stability of dry-mix thermal insulation mortar, and the inability to effectively control the setting time. The effect of controlling the construction operation time, conducive to production quality control and excellent construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

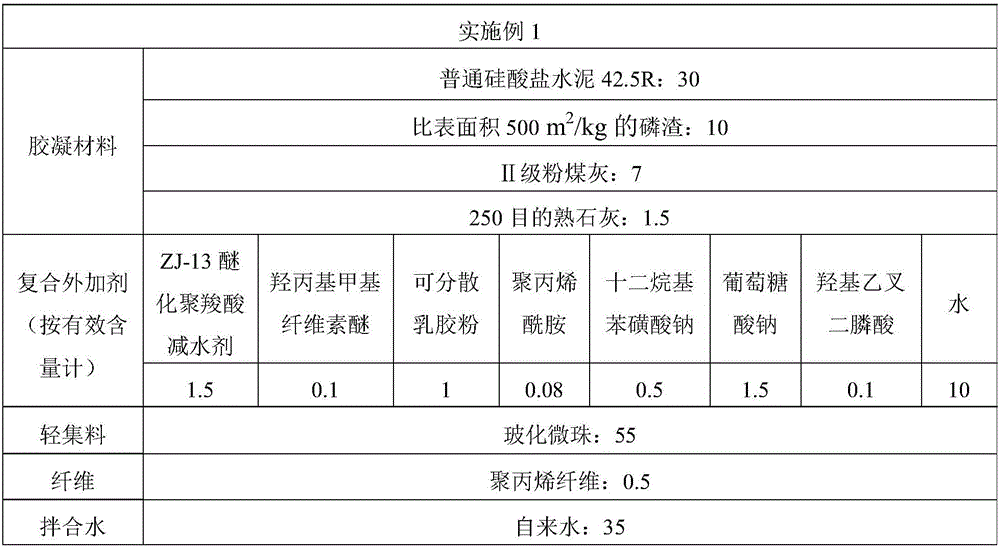

[0041] A non-shrinking wet-mix thermal insulation mortar mixed with phosphorus slag, its composition is shown in Table 1 in parts by mass.

[0042] Table 1

[0043]

[0044]In this example, among the composite admixtures for wet-mixed thermal insulation mortar, ZJ-13 etherified polycarboxylate superplasticizer has a molecular weight of 50,000, a water reducing rate of 32-34%, and a solid content of 42-43% by weight; cellulose hydroxyalkyl ether It is hydroxypropyl methylcellulose ether, its molecular weight is about 500,000; the dispersible latex powder is vinyl acetate-ethylene-acrylate copolymer latex powder, with a fineness of 0.3-7 μm; the molecular weight of polyacrylamide is 50,000; twelve Sodium alkylbenzene sulfonate is a white powder, analytically pure, with a purity of 90%; sodium gluconate is a light brown liquid with an active component of about 35-37 wt%; hydroxyethylidene diphosphonic acid is a light yellow transparent liquid with an active component of 42-30%...

Embodiment 2

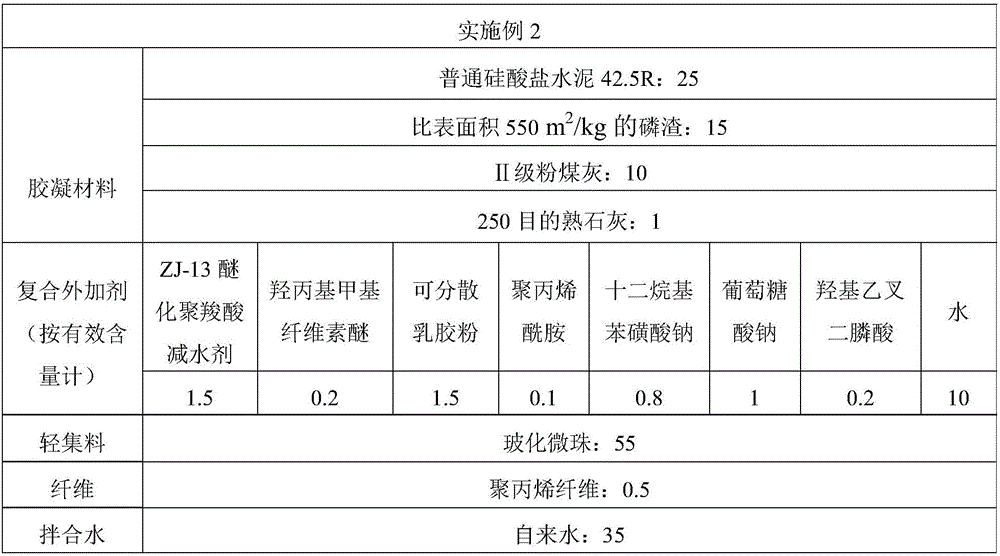

[0055] A non-shrinking wet-mix thermal insulation mortar mixed with phosphorus slag, its composition is shown in Table 3 in parts by mass.

[0056] table 3

[0057]

[0058] In this example, among the composite admixtures for wet-mixed thermal insulation mortar, ZJ-13 etherified polycarboxylate superplasticizer has a molecular weight of 50,000, a water reducing rate of 32-34%, and a solid content of 42-43% by weight; cellulose hydroxyalkyl ether It is hydroxypropyl methylcellulose ether with a molecular weight of about 1,000,000; the dispersible latex powder is vinyl acetate-ethylene-acrylate copolymer latex powder with a fineness of 0.3-7 μm; the molecular weight of polyacrylamide is 60,000; twelve Sodium alkylbenzenesulfonate is a white powder, analytically pure, with a purity of 90%; sodium gluconate is a light brown liquid, with an active component of about 35-37wt%; hydroxyethylidene diphosphonic acid is a light yellow transparent liquid, with an active component of 42...

Embodiment 3

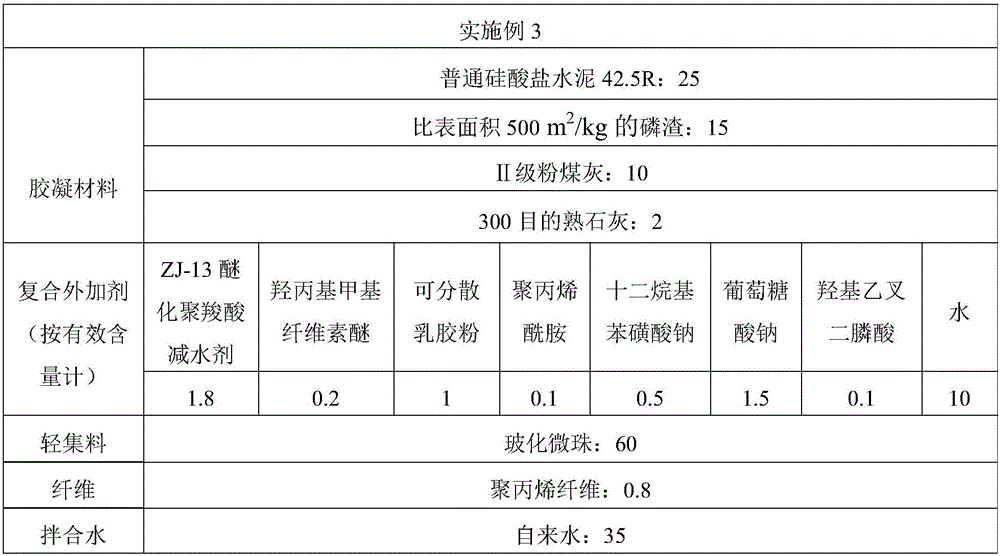

[0069] A non-shrinking wet-mix thermal insulation mortar mixed with phosphorus slag, the composition of which is shown in Table 5 in parts by mass.

[0070] table 5

[0071]

[0072] In this example, among the composite admixtures for wet-mixed thermal insulation mortar, ZJ-13 etherified polycarboxylate superplasticizer has a molecular weight of 50,000, a water reducing rate of 32-34%, and a solid content of 42-43% by weight; cellulose hydroxyalkyl ether It is hydroxypropyl methylcellulose ether, its molecular weight is about 1,000,000; the dispersible latex powder is vinyl acetate-ethylene-acrylate copolymer latex powder, with a fineness of 0.3-7 μm; the molecular weight of polyacrylamide is 60,000; twelve Sodium alkylbenzene sulfonate is a white powder, analytically pure, with a purity of 90%; sodium gluconate is a light brown liquid with an active component of about 35-37 wt%; hydroxyethylidene diphosphonic acid is a light yellow transparent liquid with an active compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com