Winching equipment

A technology of equipment and reels, applied in hoisting devices, spring mechanisms, etc., can solve problems such as tension conversion, industrial accidents, and molten iron flow interruption, and achieve the effects of avoiding equipment damage, safety accidents, and operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

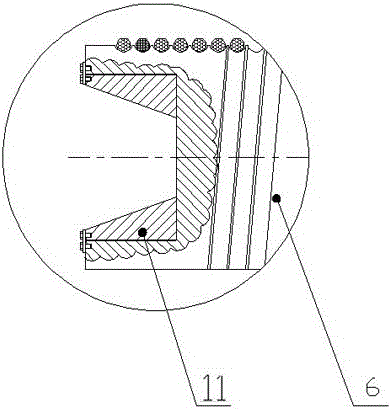

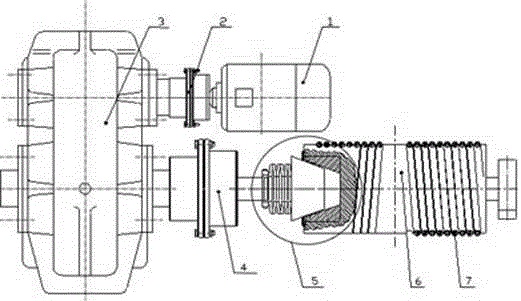

[0019] Such as figure 1 As shown, a hoisting device includes a motor 1 and a motor coupling 2 connected in sequence, a reducer 3, a reel coupling 4, and a reel body 6, and a steel wire rope 7 is provided outside the reel body. The hoisting equipment also includes a tension adjustment device 5 arranged between the drum body 6 and the drum coupling 4. The hoisting equipment uses the tension adjustment device 5 to cope with sudden changes in the tension of the wire rope during operation, ensuring that the hoisting device Yang equipment can cooperate with other equipment in a timely and accurate manner.

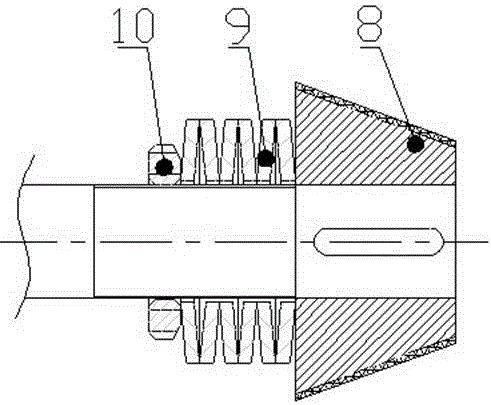

[0020] Such as figure 2 , 3 As shown, the tension adjusting device 5 includes a taper sleeve 8 that is movably sleeved on the output shaft of the drum coupling 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com