Anti-scrawling heat transfer film for leathers and preparation method thereof

An anti-graffiti and heat transfer technology, applied in the temperature recording method, etc., can solve the problems of difficult cleaning, poor abrasion resistance and solvent resistance, etc., and achieve the effect of bright colors, good abrasion resistance and solvent resistance, and enhanced toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

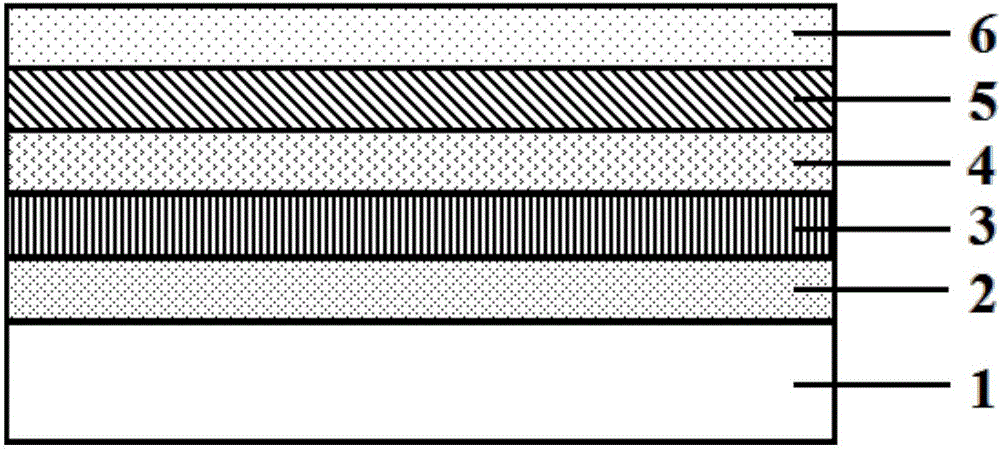

Image

Examples

Embodiment 1

[0041] Embodiment 1 of a preparation method for an anti-graffiti thermal transfer film for leather: a preparation method for an anti-graffiti thermal transfer film for leather, the preparation steps are as follows:

[0042] Step 1: Take the biaxially stretched polyester film as the base film, hereinafter referred to as the PET base film;

[0043] Step 2: Coating on the surface of the PET base film to form a release layer: mix cellulose acetate and organic solvent evenly to prepare a release layer material solution, and apply the material solution evenly on the PET base film through a 200-mesh anilox roller The surface is then reacted and dried in a five-stage oven to form a release layer. The temperature of each section of the oven is 80°C-100°C-130°C-130°C-90°C, and the speed of the machine is 80m / min. The temperature of each section of the above-mentioned oven can ensure the occurrence of curing reaction and the volatilization of organic solvents. Cooperating with the corres...

Embodiment 2

[0050] Embodiment 2 of a preparation method of an anti-graffiti thermal transfer film for leather: a preparation method of an anti-graffiti thermal transfer film for leather, the preparation steps are as follows:

[0051] Step 1: Take the biaxially stretched polyester film as the base film, hereinafter referred to as the PET base film;

[0052] Step 2: Coating on the surface of the PET base film to form a release layer: Mix cellulose acetate and an organic solvent evenly to prepare a release layer material solution, and evenly coat the material solution on the PET base film through a 250-mesh anilox roller The surface is then reacted and dried by a five-stage oven to form a release layer. The temperature of each section of the oven is 90°C-120°C-140°C-140°C-100°C, and the vehicle speed is 110m / min. The temperature of each section of the oven can ensure the occurrence of resin curing reaction and the volatilization of organic solvents. Cooperating with the corresponding vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com