A kind of organosilicon water-based paint and preparation method thereof

A silicone water-based coating technology, applied in the direction of coating, etc., can solve the problems of inability to achieve anti-graffiti organic silicon segment density, weakened anti-graffiti and anti-fouling capabilities, and inability to fully stretch, achieving high productivity and good anti-corrosion Doodle, simple effect of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Two of the purpose of the present invention is achieved by the following technical solutions: a method for preparing an organosilicon water-based coating, comprising the steps of:

[0036] (1) Add an organic solvent into a four-neck flask equipped with a stirring paddle, a thermometer and a condenser tube, and heat up to 100-160°C;

[0037] (2) Mix the modified hydroxyacrylic resin and the initiator, stir to make the mixture evenly, and form part A;

[0038] (3) Stir the fluorine-containing polysiloxane to make the mixture uniform and form part B;

[0039](4) Put part B into the flask, put part A into the dripping device, and add it dropwise at a constant speed within 2-5 hours; after the dropwise addition, raise the temperature by 5-10°C and keep it warm for 2 hours;

[0040] (5) Lower the temperature to 70°C or below, add additives, stir for 10-30 minutes and discharge.

[0041] Further, the preparation method of the fluoropolysiloxane is as follows: first vacuumize...

Embodiment 1-5

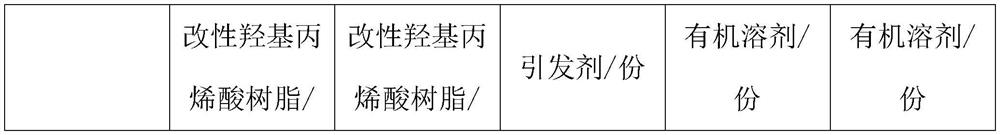

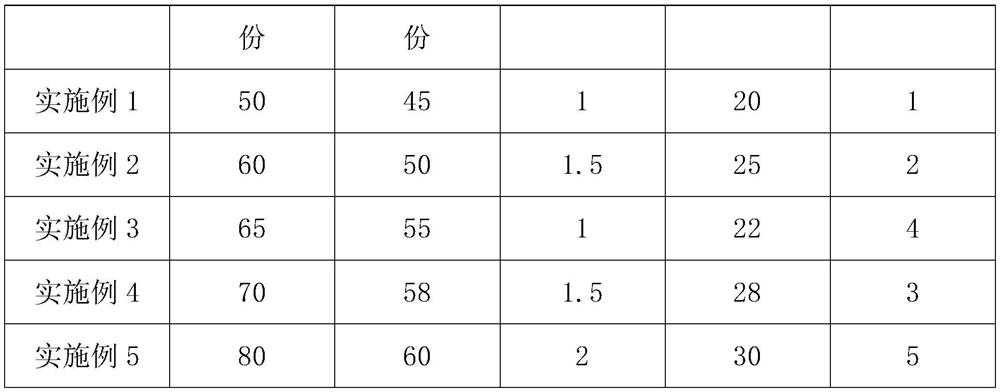

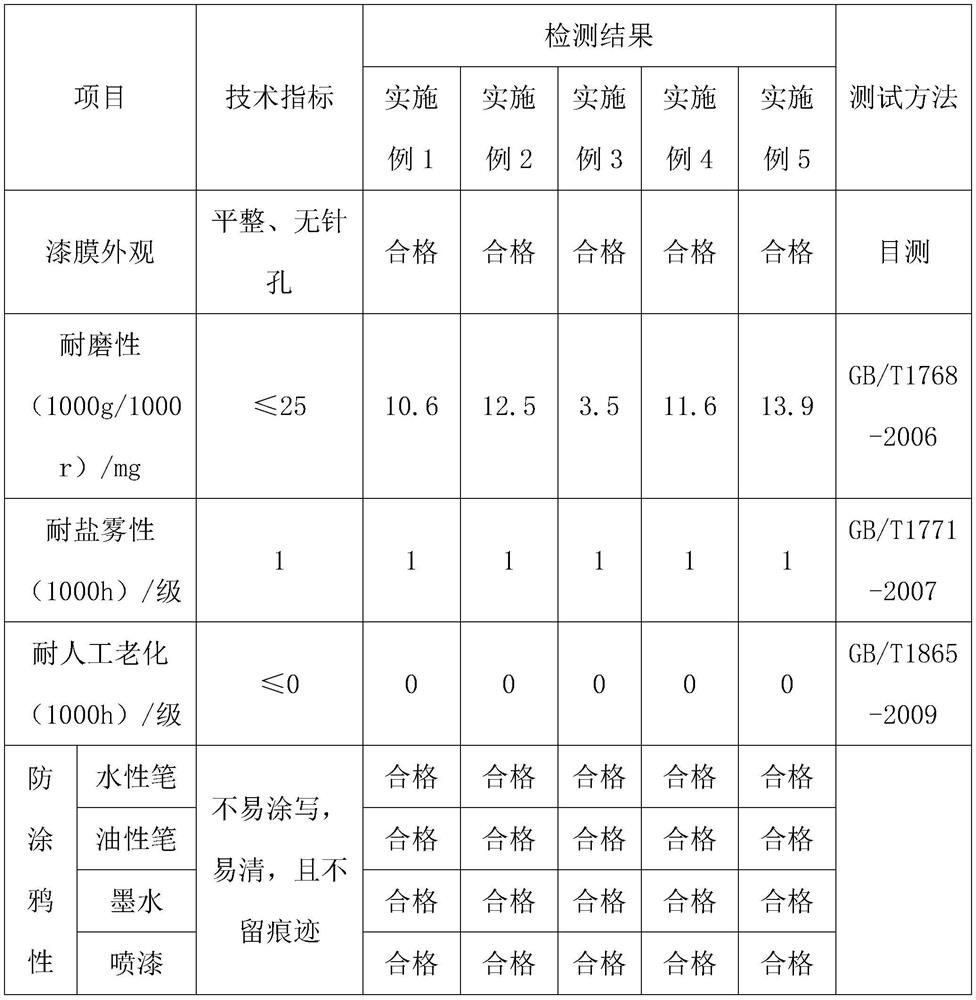

[0043] The raw materials were weighed according to the proportions in Table 1, and prepared according to the following steps, the difference being that the added raw material proportions were different, and the products were prepared, see Table 1 for details:

[0044] Table 1: Raw material ratio table of embodiment 1-5

[0045]

[0046]

[0047] Wherein, the modified hydroxy acrylic resin has a value of 80-150 mgKOH / g, and a number average molecular weight of 2000-20000 g / mol.

[0048] The preparation method of fluorine-containing polysiloxane is as follows: first vacuumize the reaction device, and keep the vacuum degree at 1.5×10 -1 pa; remove oxygen and moisture, and then pass nitrogen protection; add 50 parts by weight of fluorosilicone oil, 10 parts by weight of trimethoxysilane, 50 ppm of Speier catalyst, and 20 parts by weight of toluene, and stir evenly; react at 70 ° C for 3 hours; the product Transfer to a reduced pressure rotary evaporator at 1.5 x 10 -1 Unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com