Transformer substation inspection robot

A technology for inspection robots and substations, applied in manipulators, manufacturing tools, etc., can solve problems such as increased operating costs, and achieve the effect of reducing operating costs and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

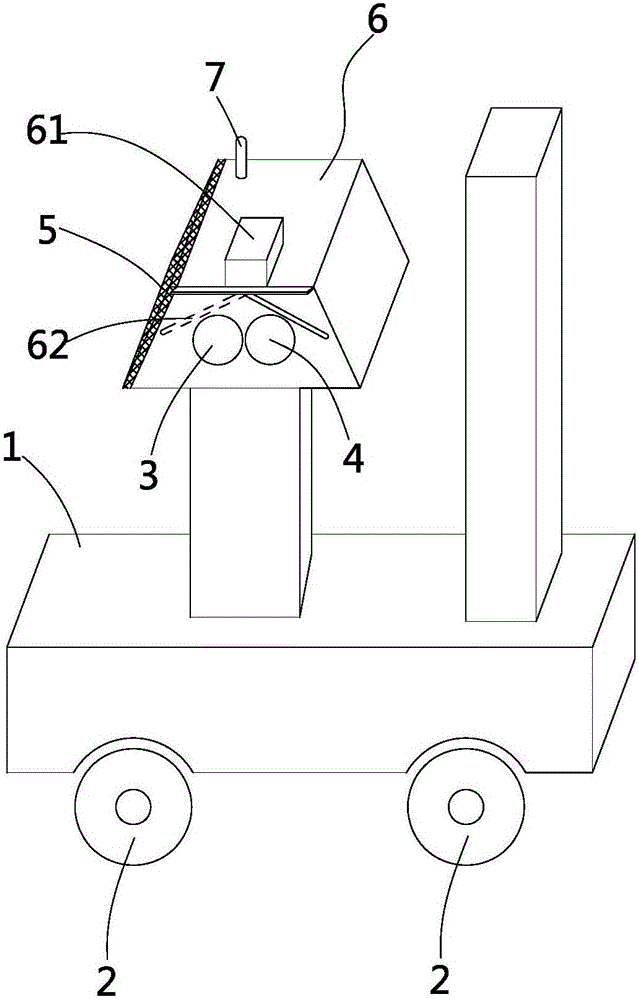

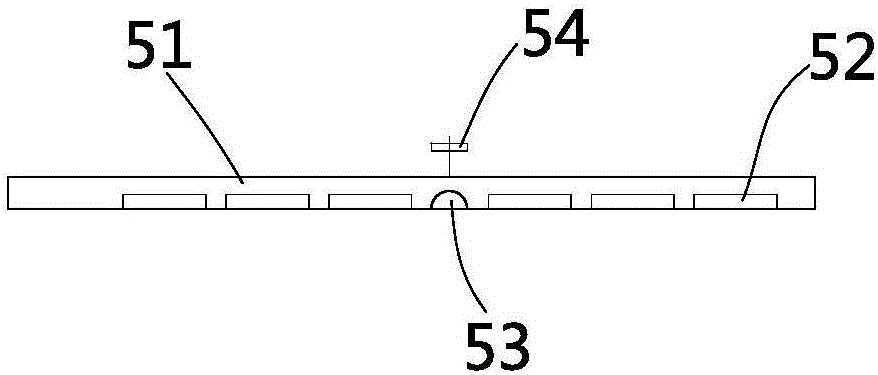

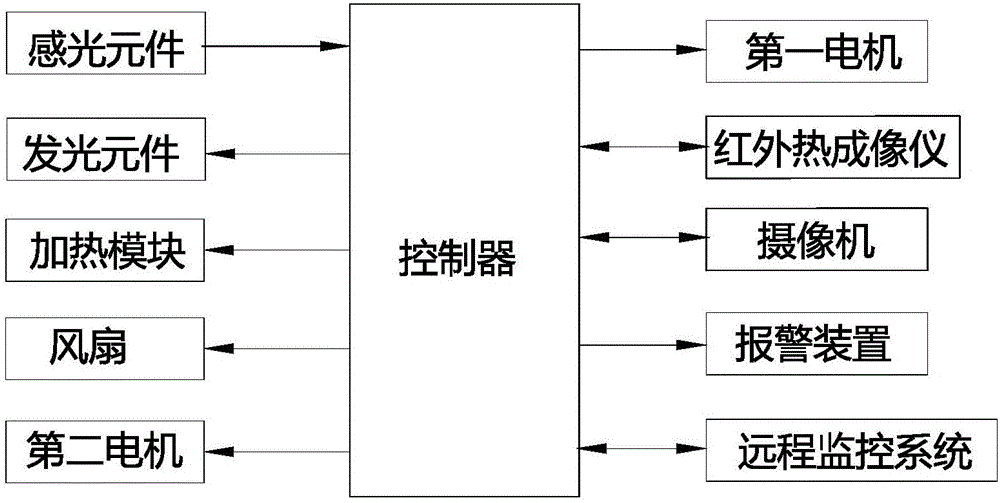

[0039] refer to Figure 1 to Figure 3 As shown, the substation inspection robot proposed in this embodiment includes a body 1, on which a power supply unit, a controller, a traveling mechanism 2 and a first motor for driving the movement of the traveling mechanism are arranged, and the controller controls the driving of the first motor. Running mechanism 2 walks or stops. A camera 3 and an infrared thermal imager 4 connected to the controller are installed on the body 1. The body 1 also includes a mount 6 for installing the camera 3 and the infrared thermal imager 4. The power supply unit includes a controller, a first motor The solar cell panel 5 powered by electronic components, etc., the solar cell panel 5 is installed on the top surface of the mount 6, the solar cell panel 5 includes tempered glass 51 and a power generation body 52, and the tempered glass 51 and the power generation body 52 are bonded by EVA.

[0040] Compared with the prior art, the solar panel 5 of the ...

Embodiment 2

[0044] Such as Figures 4 to 5 As shown, the outer surface of the lens of the camera 3 in the present embodiment is coated with a hydrophobic film 7, and the outer surface of the lens of the infrared thermal imager 4 is coated with a hydrophobic film 7. In rainy and snowy weather, the hydrophobic film can make the The water droplets on the top form water droplets and slide down quickly to prevent the water droplets from adhering to the lens surface and affecting the imaging quality. This design makes the structure simpler.

[0045] In addition, the infrared thermal imager 3 of the present embodiment also includes a first housing 31 and a first lens 30, the first lens 30 is installed on the first housing 31, and there is also a device connected to the controller in the first housing 31. The heating module 8 is a heating resistor or a silicon rubber heating film, and the heating module 8 is arranged on the inner wall of the first casing 31 close to the first lens 30 . When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com