Tool for fixing grinding ring for high-pressure flange sealing face

A technology of grinding ring and cover, applied in grinding devices, grinding tools, grinding machine tools, etc., can solve the problems of high precision of high-pressure flange sealing surface, damage of sealing surface grinding deformation, obvious influence of gravity, etc., to reduce physical strength and convenience. Operation to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

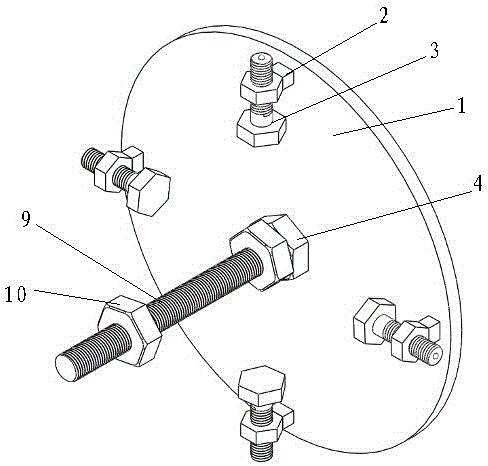

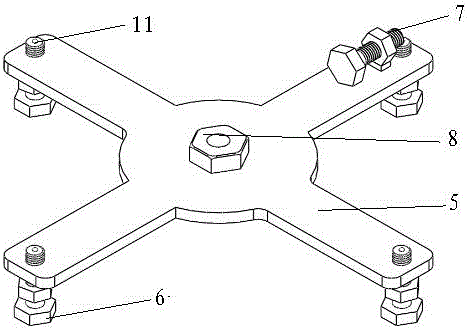

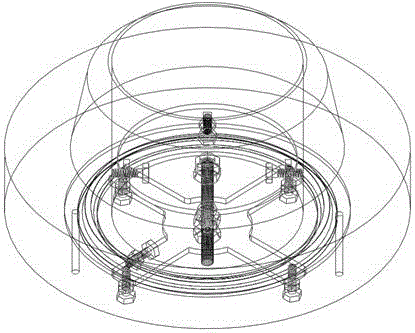

[0025] As shown in the accompanying drawings, a tooling for fixing the grinding ring 12 on the sealing surface of a high-pressure flange according to this patent is composed of an inner fixing disc 1 component, an outer fixing disc component and a connecting screw 9 component;

[0026] The internal fixed plate assembly includes an internal fixed plate 1, a spacer 2, a fixed bolt 3 with a nut, and a central nut 4; the center of the internal fixed plate 1 is provided with a round hole, and the spacer 2 is arranged on the circular surface of the lower side of the internal fixed plate 1 Above, each spacer 2 is evenly distributed on the circumference; the nut of the fixing bolt 3 with nut is fixedly connected with the spacer 2, and the fixing bolt 3 is arranged axially and horizontally, which is consistent with the radial direction of the inner fixing plate 1; the central nut-4 is connected with the inner fixing The circular hole at the center of the disk 1 is arranged concentricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com