Automobile elbow welding device

A welding device and pipe bending technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment and other directions, can solve problems such as low processing efficiency, threat to driver's life safety, affecting vehicle safety performance, etc., to improve processing quality and efficiency, The cutting time is shortened and the effect of avoiding poor welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

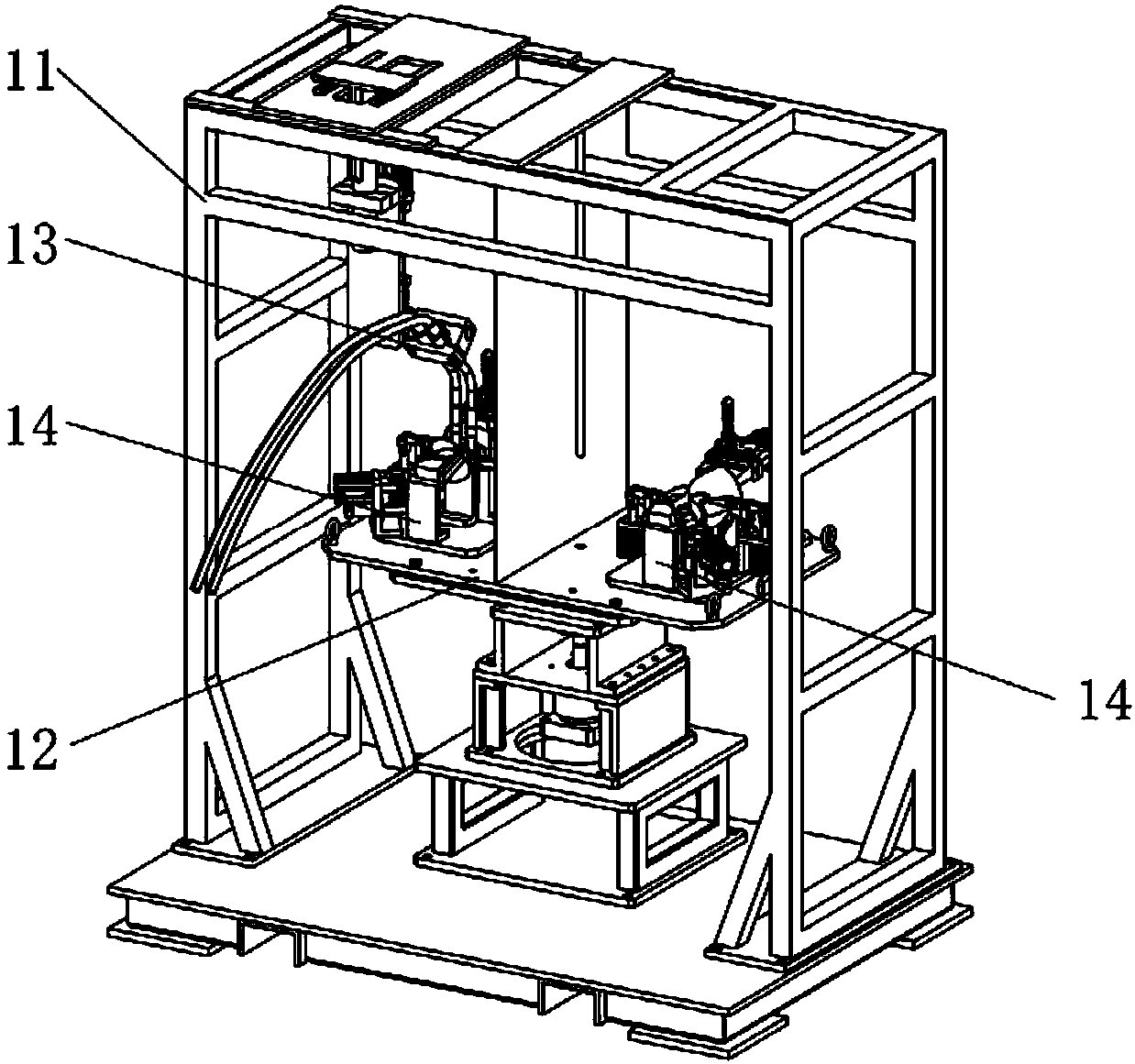

[0026] figure 1 Shown is the overall structure of the automobile bending pipe welding device, which is used to weld the bending pipe 100 and the bending plate 200 together, and mainly includes a frame 11, a workbench 12 installed in the middle of the frame 11, an installation The welding torch assembly 13 on the top of the frame 11 and the welding positioning fixture 14 installed on the workbench 12, wherein the welding torch assembly 13 and the welding positioning fixture 14 are two sets, and are symmetrically arranged with respect to the frame 11 left and right.

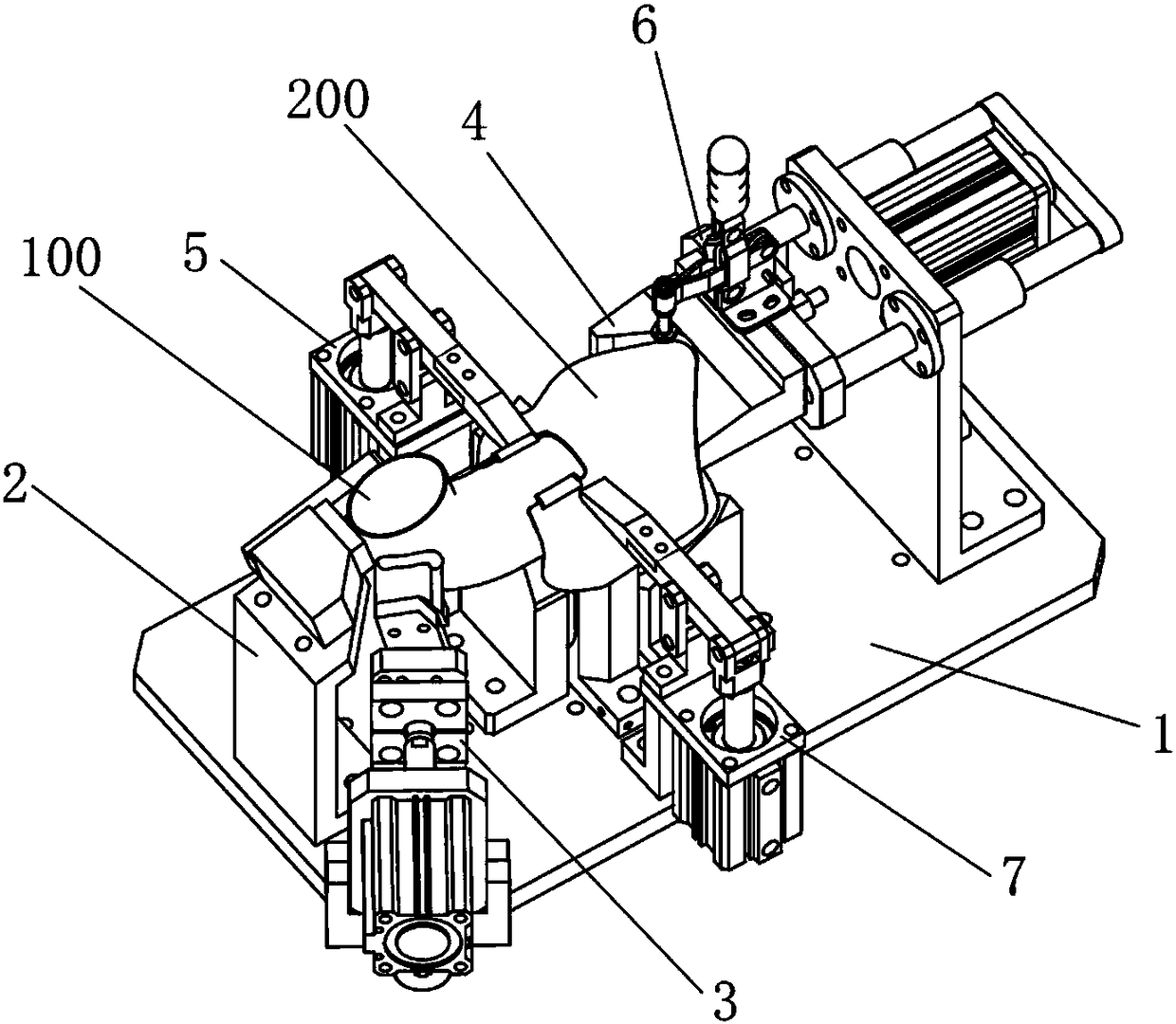

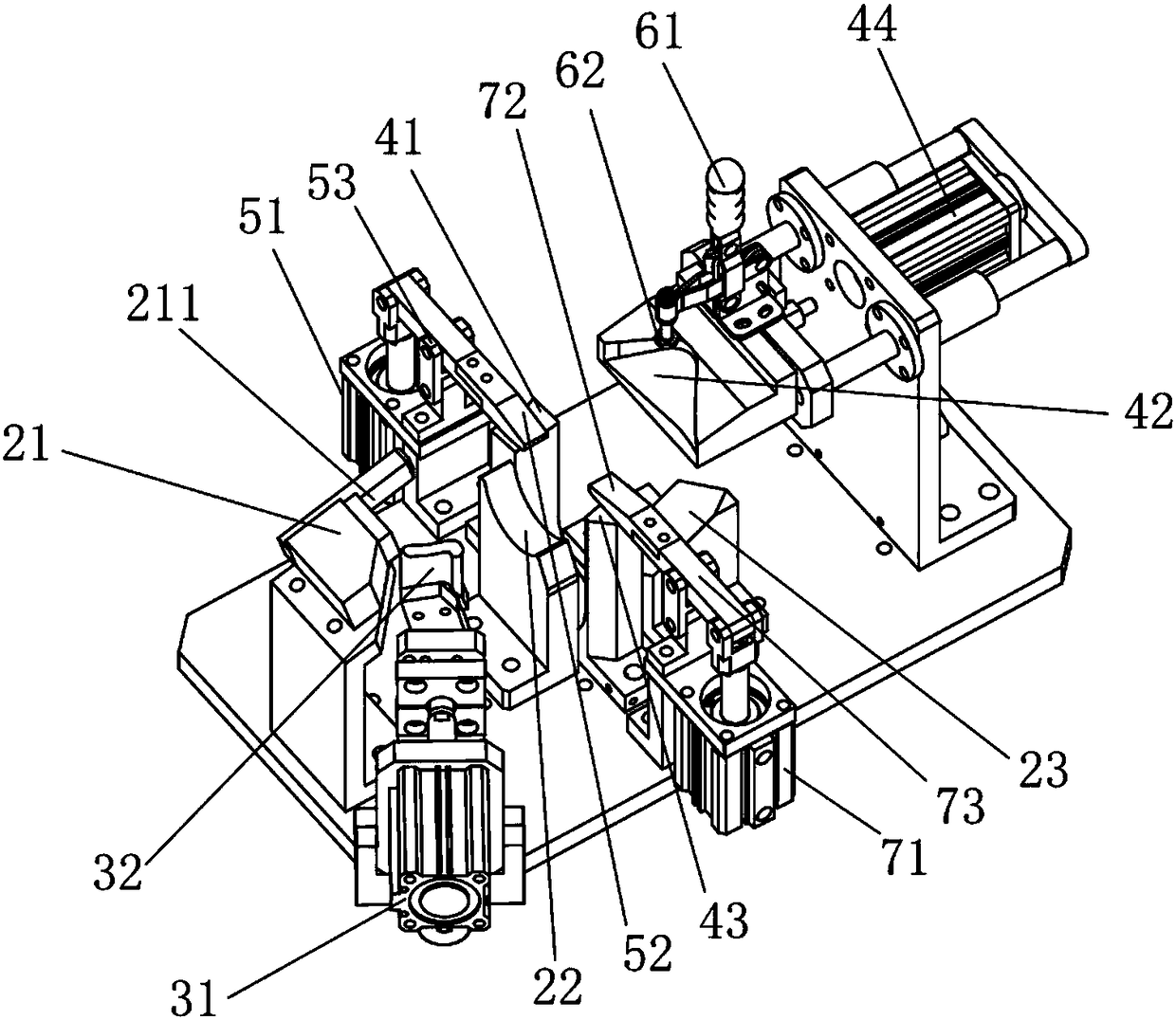

[0027] figure 2 A schematic structural view of the welding positioning jig 14 is shown, in which the bent pipe 100 and the bent plate 200 have been positioned and are in a weldable state. The welding positioning fixture 14 includes a base 1 and a first support assembly 2 installed on the base 1 for supporting the elbow 100, a first positioning mechanism 3 for positioning the elbow 100, and a support assembly for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com