Milling method of blade of high-temperature alloy whole blade ring

A high-temperature alloy, integral blade technology, applied in the field of aero-engines, can solve the problems of unreachable feed and design requirements, and achieve the effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

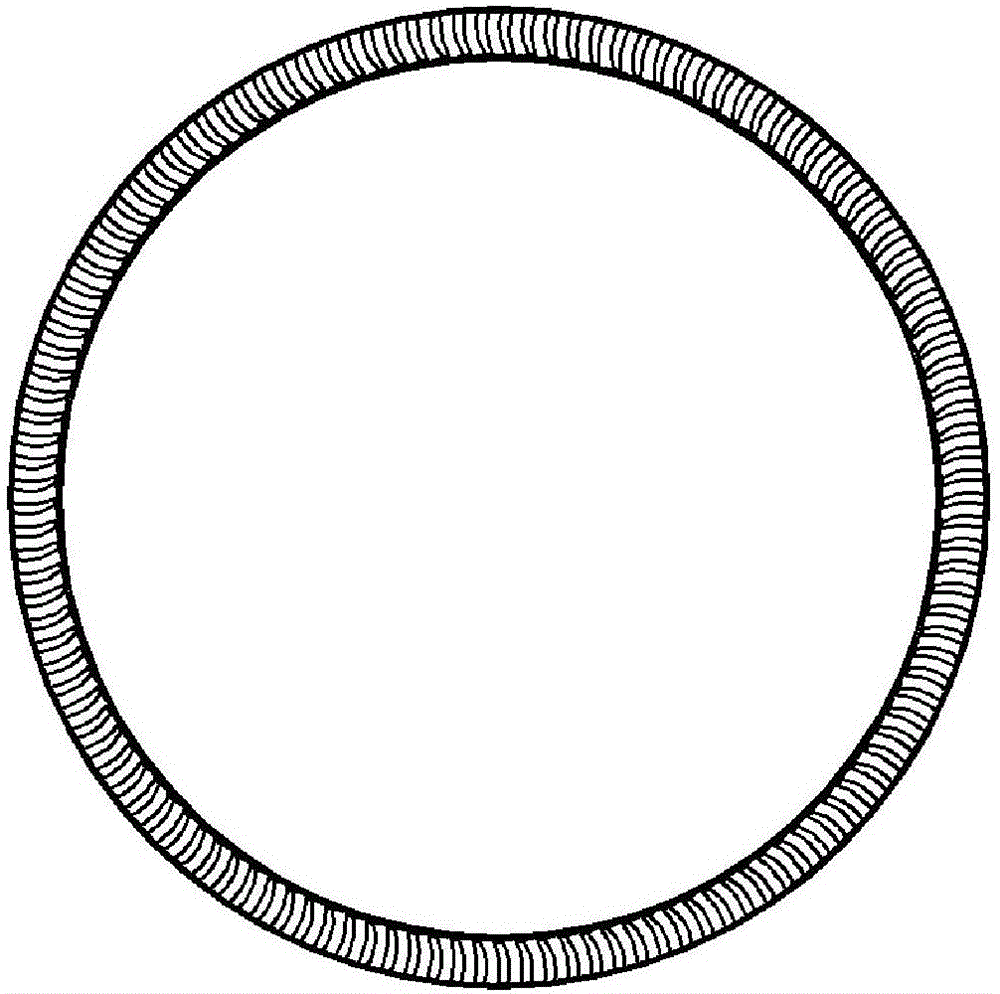

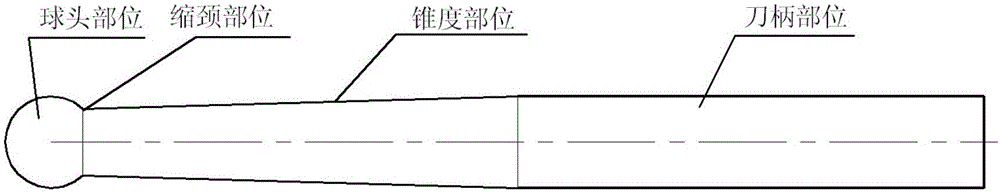

[0029] The overall leaf ring part is made of superalloy material, the material grade is GH4169, the maximum outer diameter of the leaf ring part: Φ530mm; the minimum inner flow channel diameter: Φ460mm; the thickness of the part is 30mm; the maximum chord width of the blade: 40mm; the total number of blades: 130 pieces; the minimum distance between adjacent blades: about 9mm; the thickness of the inner and outer rings of the leaf ring is 2-5mm; the length of the blades is about 30-33mm; the connection between the blades and the inner and outer flow channels is RR2.5mm. The schematic diagram of the parts is shown in the figure below.

[0030] Follow the above steps to process:

[0031] Step 1: Formulate processing procedures

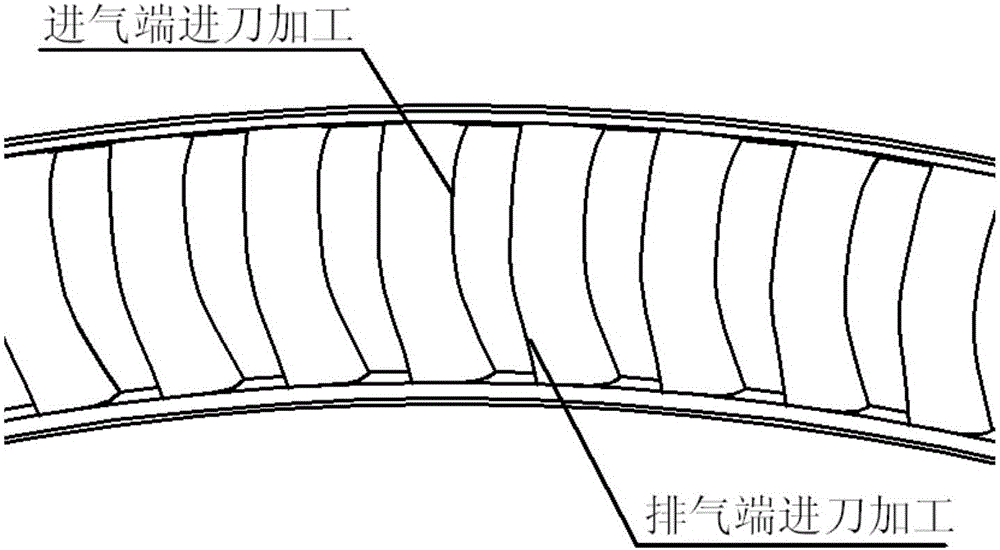

[0032] The milling process route of this type of integral leaf ring is: rough milling and slotting at the intake end → rough milling and slotting at the exhaust end → fine milling of the air inlet end profile and flow channel → fine milling of the exhaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com