Clamp for rotation milling machining of gas compressor blade profile

A technology of rotary milling and air compressor, which is applied in the direction of manufacturing tools, metal processing equipment, milling machine equipment, etc. It can solve the problems of unstable blade clamping and out-of-tolerance machining dimensions, and achieve the guarantee of machining dimensions, reliability, and stable positioning with clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

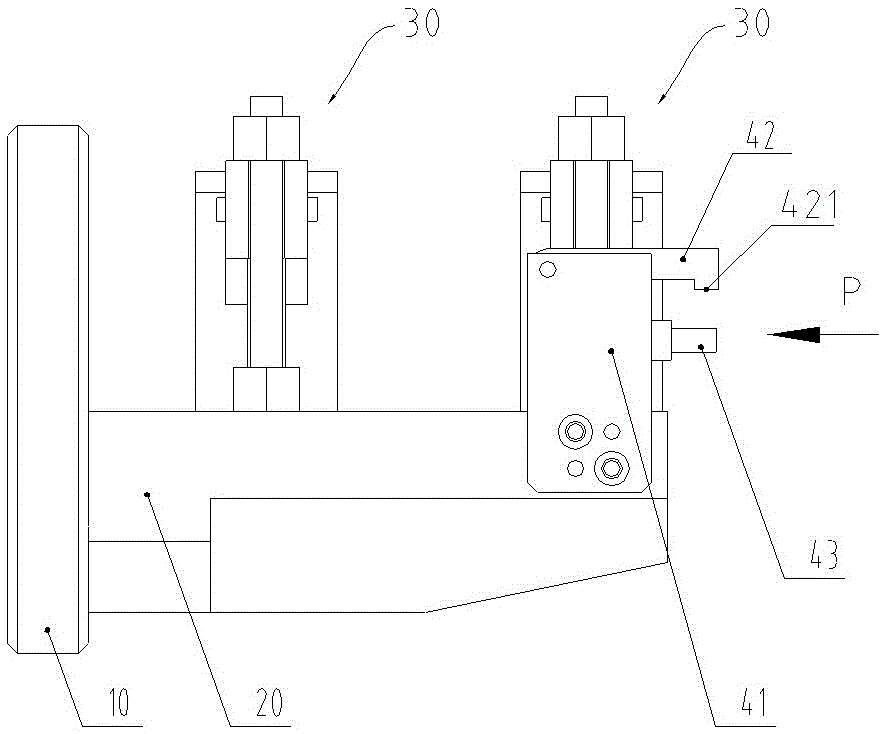

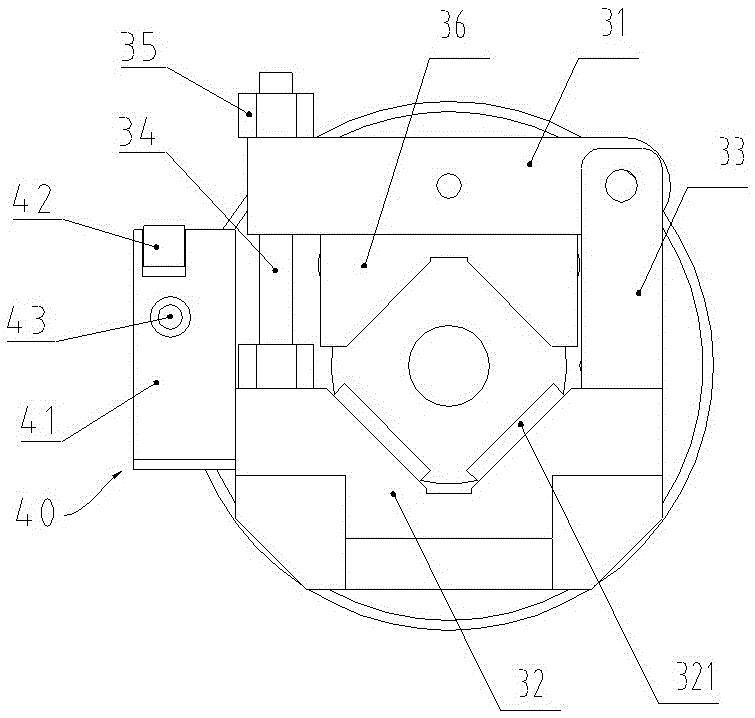

[0021] See figure 2 and image 3 , the present invention includes a rotary disc 10, a clamp body 20 is fixedly mounted on the rotary disc 10, a blade handle positioning and clamping assembly 30 is installed on the clamping body 20, and the blade positioning and clamping assembly 30 includes a pressing plate 31 and is integrally arranged on the clamp The positioning seat 32 on the specific 20, the positioning seat 32 is provided with a V-shaped positioning groove 321, and the positioning seat 32 is located at an outer end of the V-shaped positioning groove 321. A support block 33 is installed on the other outer end and a locking screw 34 is installed. One end of the compression plate 31 is flexibly connected with the support block 33, and the other end is fastened to the locking screw 34 through the lock nut 35. The bottom of the compression plate 31 is provided with an inverted V-shaped compression block 36, and the inverted V-shaped compression The tight block 36 and the V-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com