Zip line laying structure provided with searchlight

A searchlight and zipline technology, applied in the field of zipline laying structure, can solve the problems of affecting the sliding speed, unable to adjust the height and tension of the zipline, easy to break, etc., achieving low cost, suitable for popularization and use, and ensuring reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

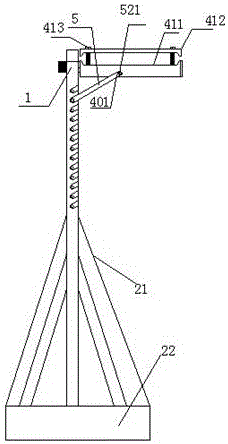

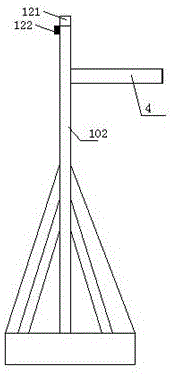

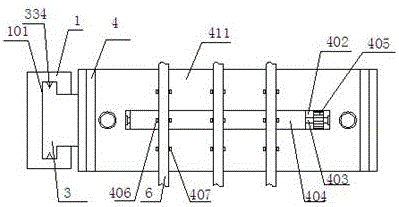

[0018] When in use, first insert the sliding block 3 on the support plate 4 into the guide groove 101, make it slide to the corresponding height that needs to be assembled, and then insert the support bar 5 into the slot 102 and the first slot 401 respectively and pass through the firm 521 is fixedly connected; rope fixing implementation 1: directly buckle the rope 6 into the corresponding first embedded buckle 407 and second embedded buckle 406 to complete the initial fixation, and then pass through the two second fastenings on the top of the cover plate 412 Part 413 is screwed into the support plate 4 to complete the fixation; rope fixing implementation 2: drive the threaded rod 403 to rotate by toggling the allocation wheel 405, and control the sliding bar 404 to slide along the direction of the allocation groove 402, so that the first on the sliding bar 404 There is a certain angle between the second buckle 406 and the first buckle 407 on the support plate 4, and the rope 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com