Manual transmission

A manual transmission and rolling element technology, which is applied to transmission parts, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of increasing the inner ring and reducing the strength, and achieve the effect of preventing relative rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings. In the drawings referred to below, the same or corresponding components will be denoted by the same reference characters.

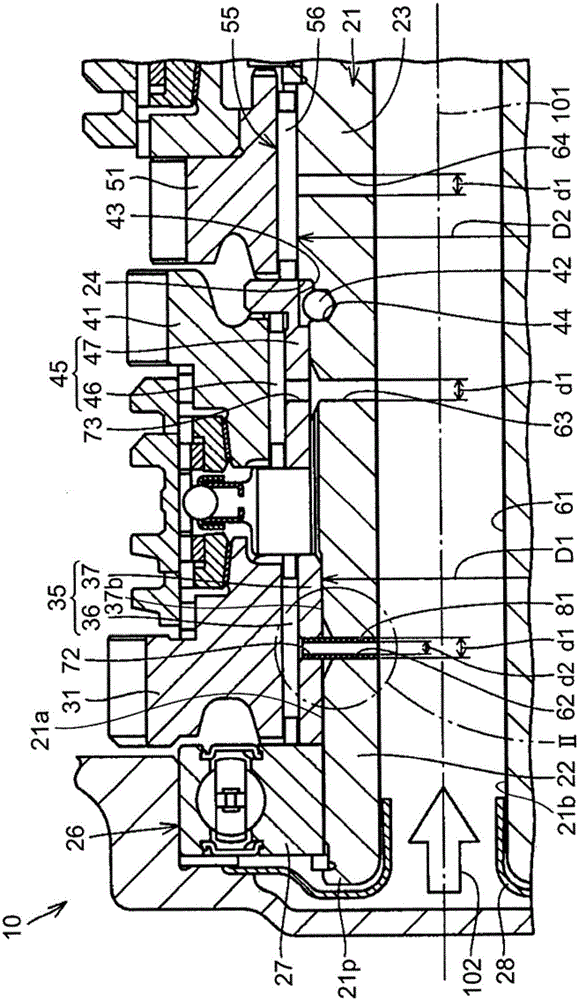

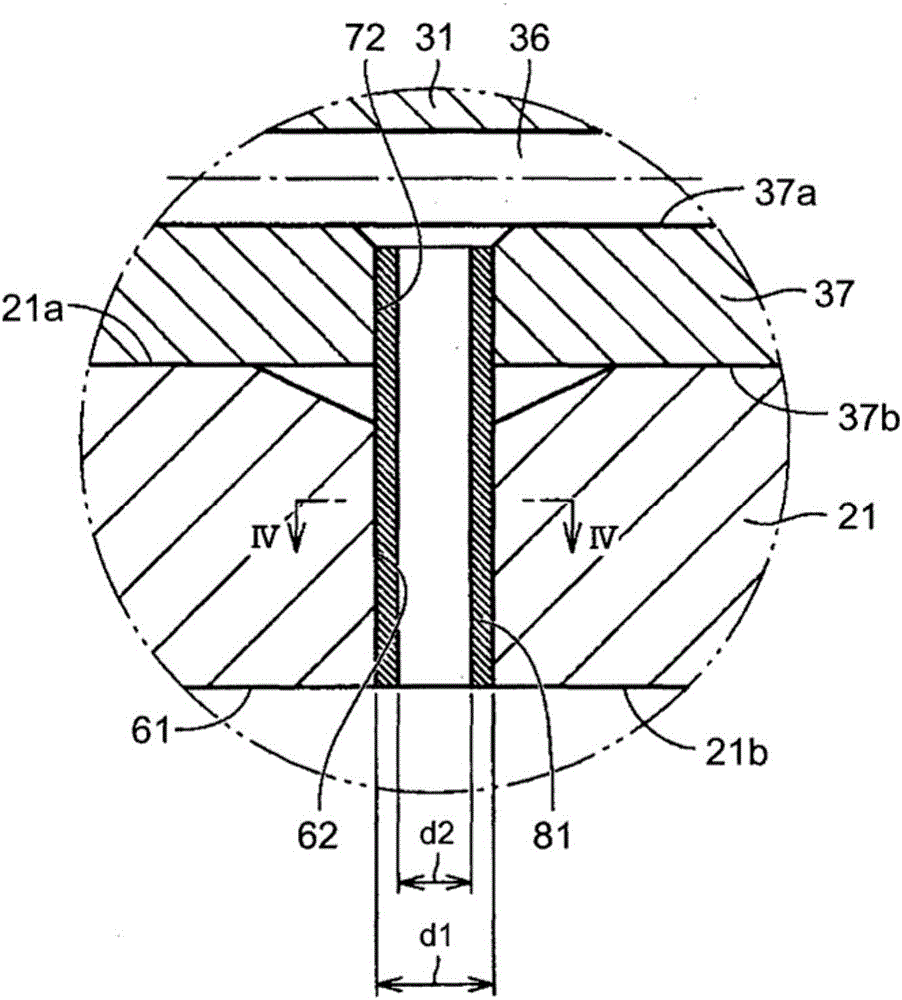

[0029] First, a first exemplary embodiment of the present invention will be described. figure 1 is a sectional view of the manual transmission according to the first example embodiment of the present invention. refer to figure 1 , the manual transmission 10 of the present exemplary embodiment is a vehicle manual transmission that selectively decelerates or accelerates the rotation generated by the power source and outputs the resultant rotation to the drive wheels, and reverses the generated rotation and transfers this This reverse rotation is output to the drive wheel.

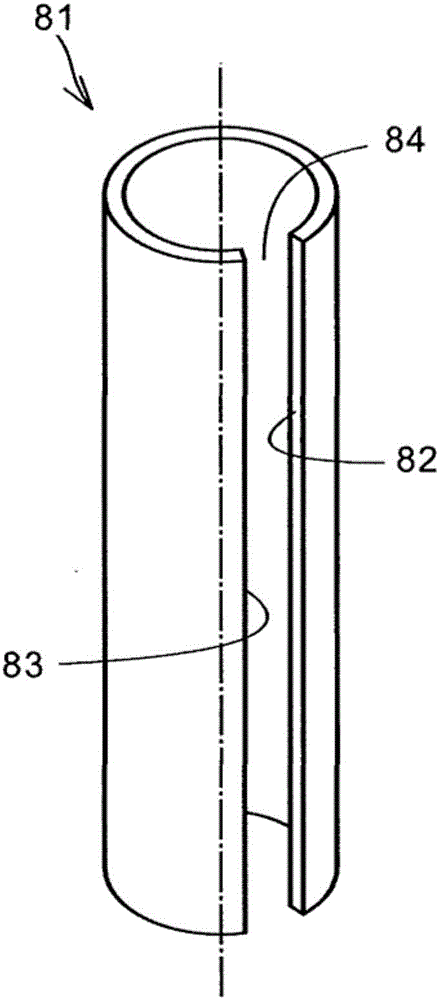

[0030] First, in describing the overall structure of the manual transmission 10 , the manual transmission 10 includes a shaft 21 , a bearing 35 , a bearing 45 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com