Hollow through-hole investment mold shell structure for vacuum suction casting process of high temperature resistant alloy

A hollow and mold shell technology is applied in the field of hollow through-hole investment mold shell structures, which can solve problems such as low output and dangerous accidents, and achieve the effects of saving casting energy, high safety factor, and fine grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

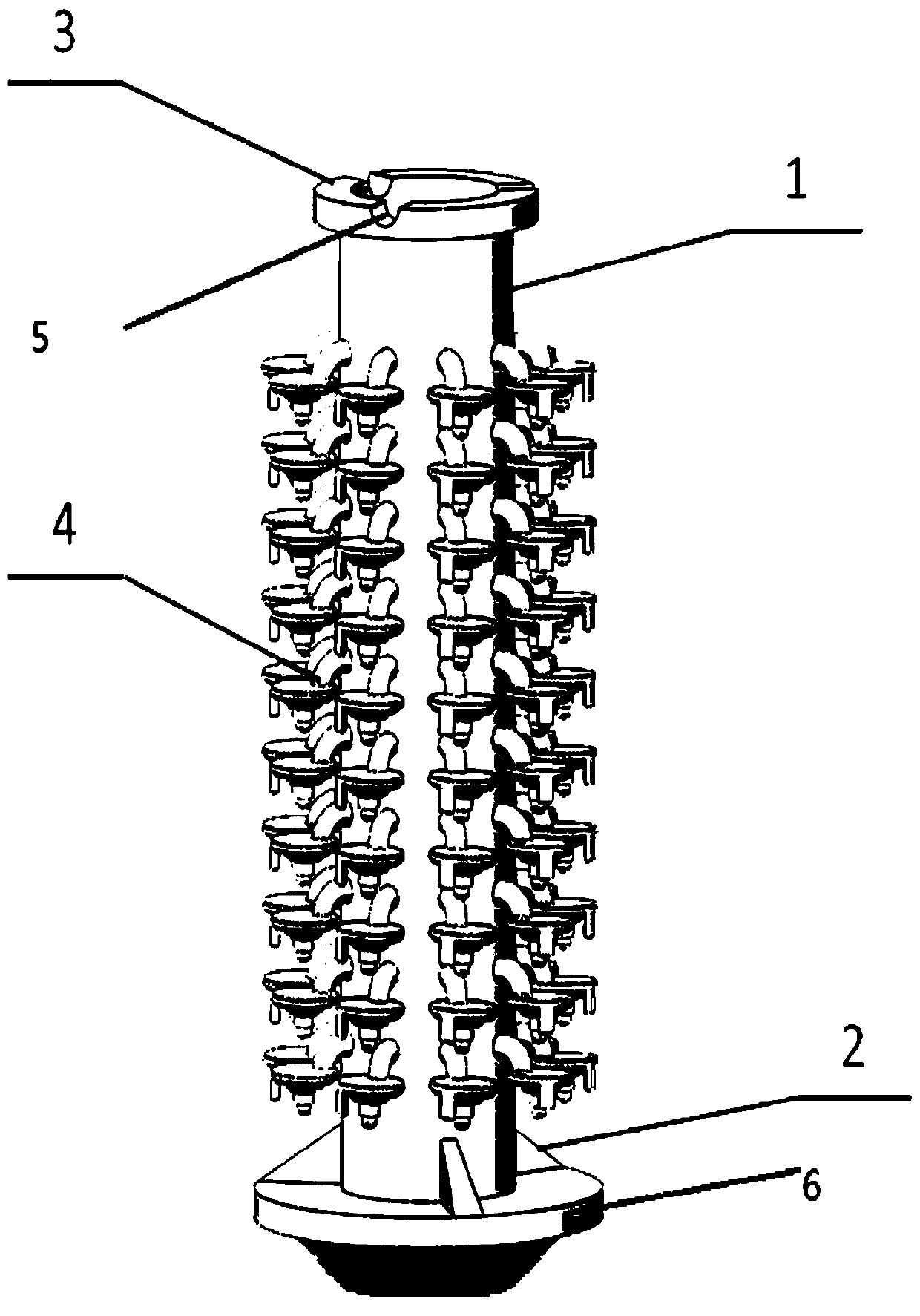

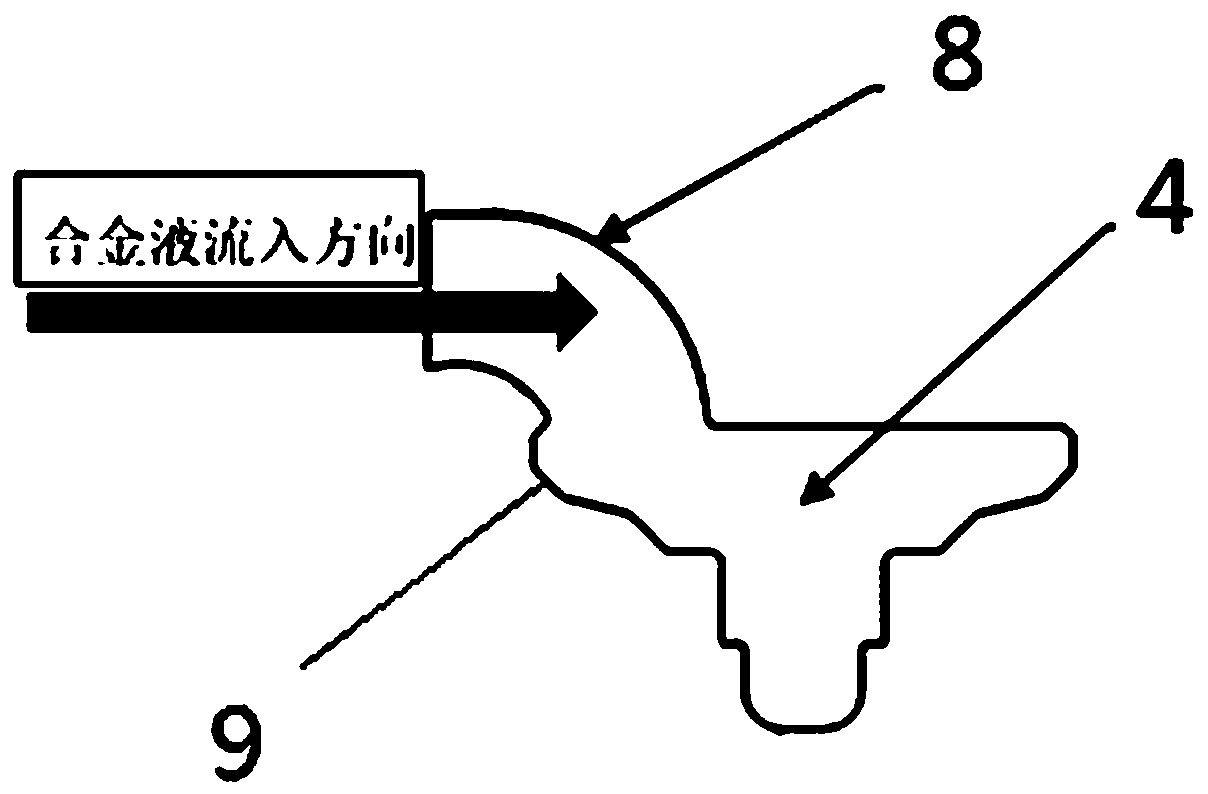

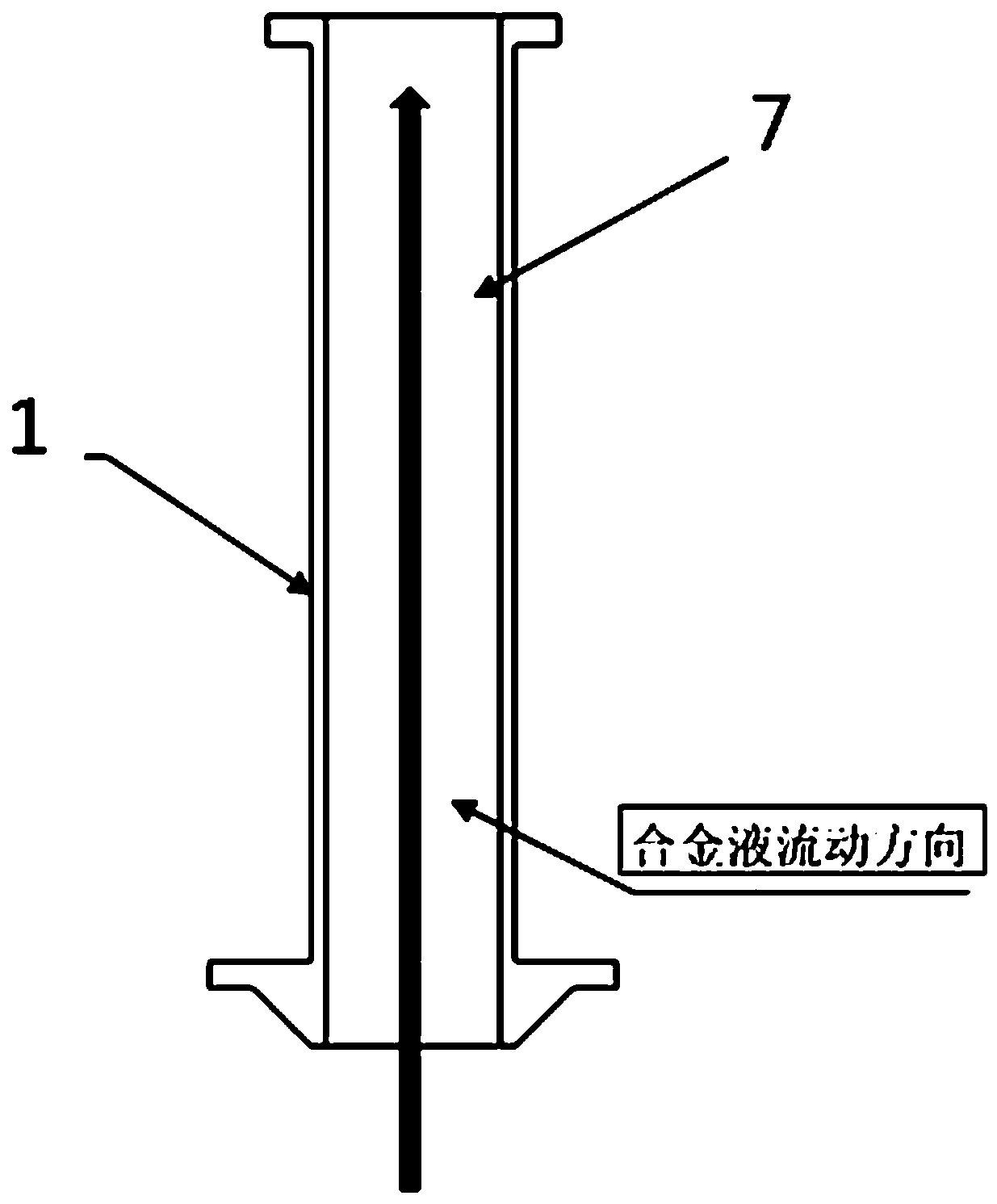

[0017] refer to figure 1 , the main body of the hollow through-hole investment mold shell structure according to the present invention is a hollow through-hole structure, and the upper part of the hollow through-hole is provided with an outwardly protruding platform and a vent hole, the platform can compress the mold shell structure, and the vent hole Effective exhaust; the lower part of the hollow through hole is provided with a base, and a reinforcing connector is provided between the base and the outer wall of the hollow through hole, which is conducive to improving the strength of the formwork structure; further, the outer wall of the hollow through hole is evenly distributed There are formwork castings, and the formwork castings are connected to the hollow passage through a runner system. The runner system includes elbow runners, filling runners and feeding runners. The design of the above runners, Conducive to filling and feeding.

[0018] The base is composed of a colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com