Simultaneous ultraviolet curing device for product of double-layer UV gel structure

A curing device and product technology, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., can solve the problem that multi-layer UV glue or ink products cannot be cured, and the curing time of UV curing agent is different, increasing Problems such as processing cost and time cost, to achieve the effect of eliminating product defects, reducing processing cost, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

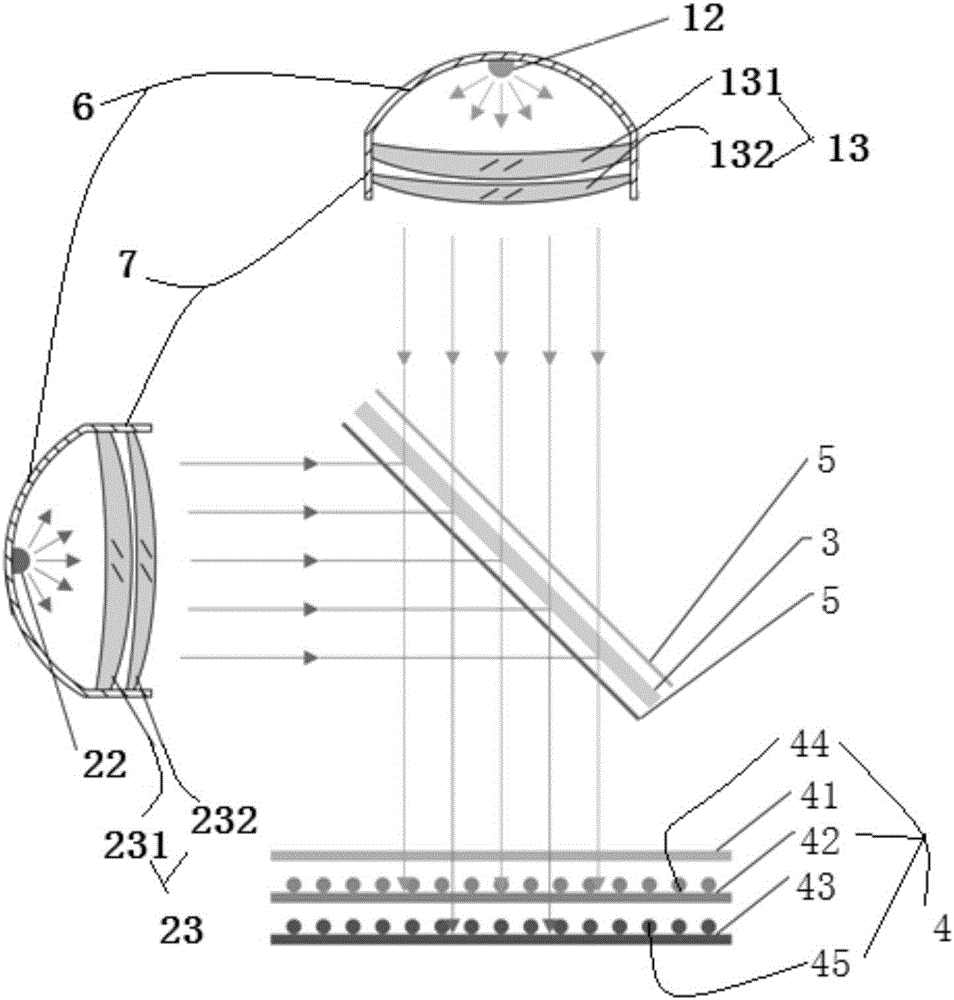

[0023] In this example, the double-layer material of the touch screen is used as an example to illustrate the simultaneous UV light curing and bonding scheme. In the current market, due to product differences and processing requirements, there are many kinds of UV adhesives, and each UV adhesive requires UV light of a corresponding wavelength. Irradiation can achieve the best curing effect. Because UV light with a wavelength of 365nm and 395nm is mostly used in current processing, this embodiment uses UV light with a wavelength of 365nm and 395nm and the corresponding UV adhesive for illustration, but this embodiment is not limited to the use of 365nm And UV light with a wavelength of 395nm and the corresponding UV adhesive touch screen double-layer material products.

[0024] The simultaneous ultraviolet curing device for the product containing double-layer UV glue structure provided by the present embodiment combines figure 1 , including the first parallel light source mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com