Coal char and urea or ammonium bicarbonate mixed pyrolysis cycle reduction system for nitrogen oxides

A technology of ammonium bicarbonate and mixed pyrolysis, applied in the field of nitrogen oxide removal system, can solve problems such as boiler efficiency decline, poor contact between reducing agent and flue gas, water wall tube burst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

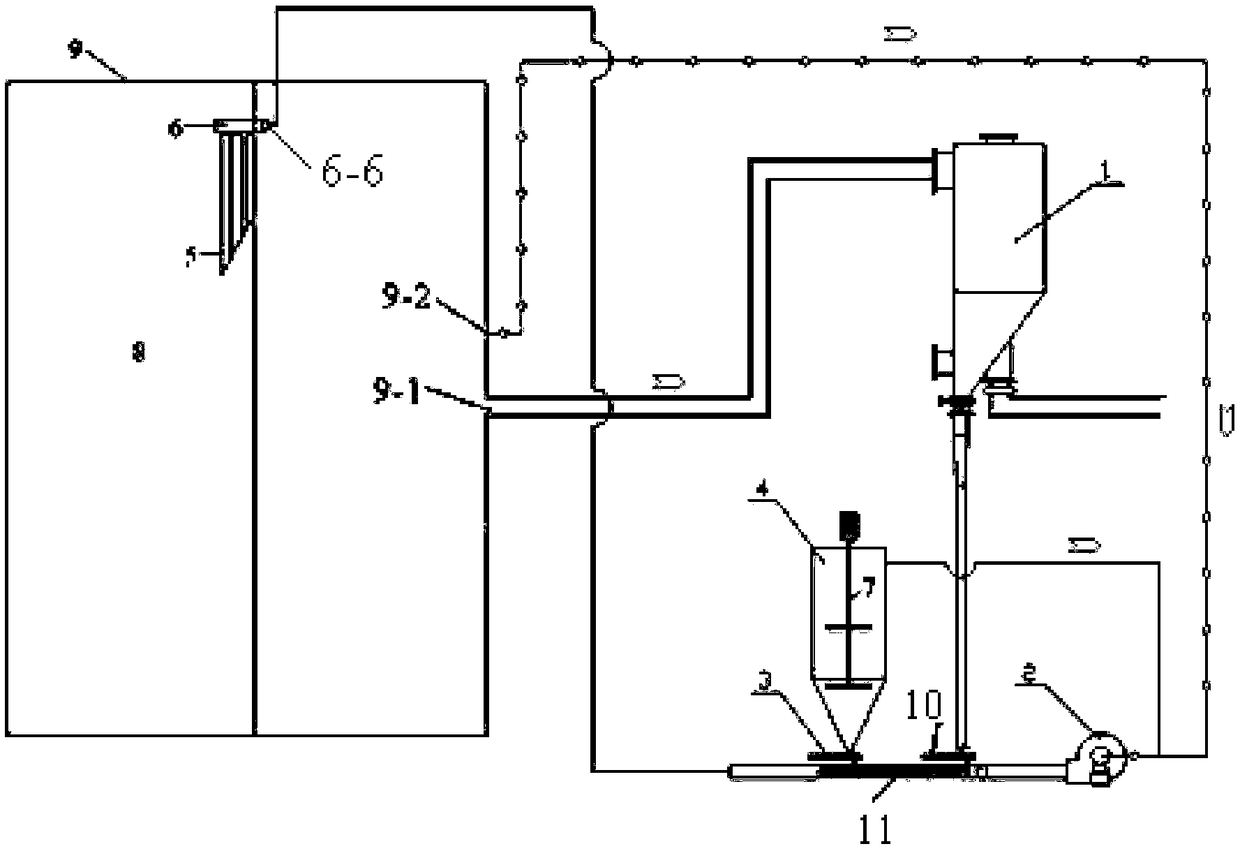

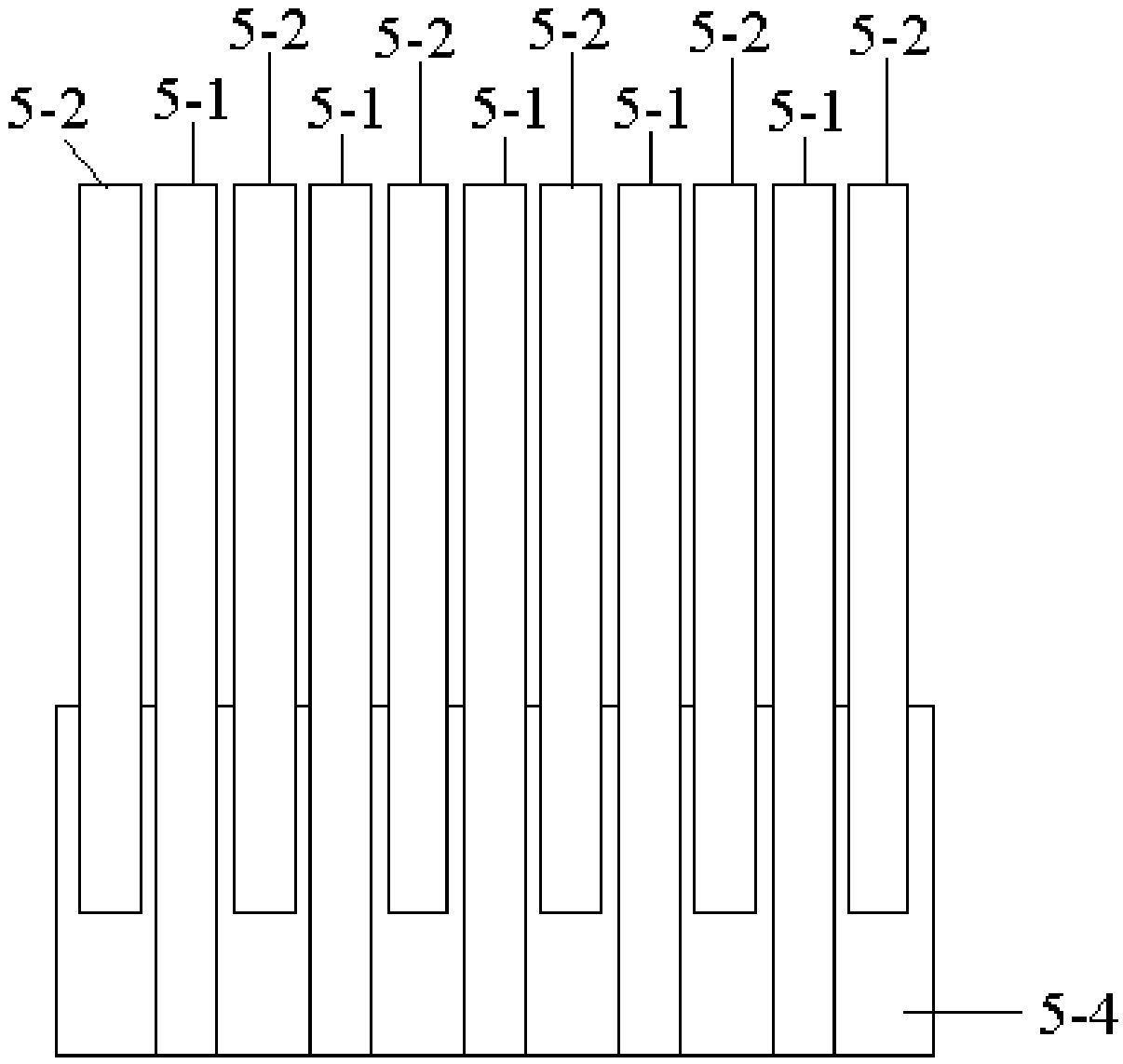

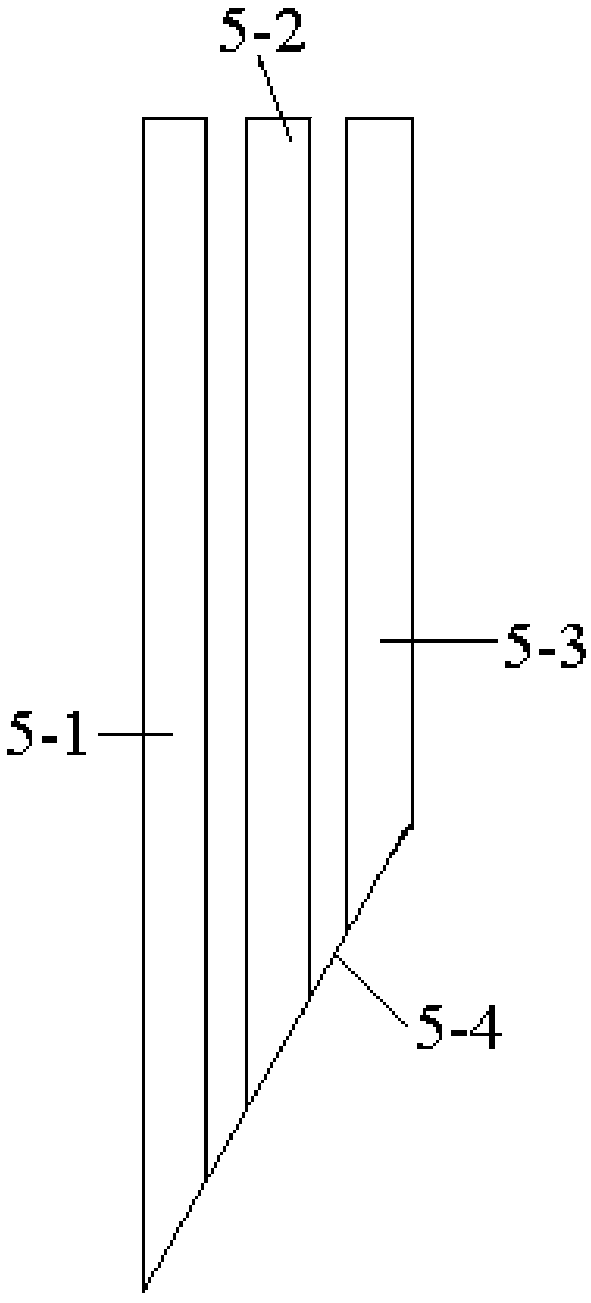

[0020] Specific implementation mode one: as Figure 1-8 , this embodiment is a system for reducing nitrogen oxides in a mixed pyrolysis cycle of coal char and urea or ammonium bicarbonate, specifically consisting of a boiler 9, a first-stage pre-dust collector 1, an induced draft fan 2, a first feeder 3, a second It consists of a feeder 10, a reducing agent storage tank 4, an agitator 7, a pipeline 11, a trough array mixer 5 and a distribution header 6;

[0021] The distribution header 6 is composed of the first straight pipe 6-4, the second straight pipe 6-1, the third straight pipe 6-2, the fourth straight pipe 6-7, the fifth straight pipe 6-5 and 16 Composed of three nozzles 6-3; the first straight pipe 6-4 and the second straight pipe 6-1 are arranged in parallel, the third straight pipe 6-2, the fourth straight pipe 6-7 and the fifth straight pipe 6-5 are arranged in parallel , the third straight pipe 6-2, the fourth straight pipe 6-7 and the fifth straight pipe 6-5 are ...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the boiler 9 is an industrial boiler. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the material of the trough array mixer 5 is high temperature resistant metal. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com