Online intelligent tobacco curing system based on cloud platform and curing process

A flue-cured tobacco system and cloud platform technology, applied in the field of baking equipment and baking technology, can solve the problems of dry tobacco leaves being easily broken, unable to be directly collected, and slow moisture regain of tobacco leaves, so as to improve the turnover cycle, solve the shortage of tobacco technicians, reduce the The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

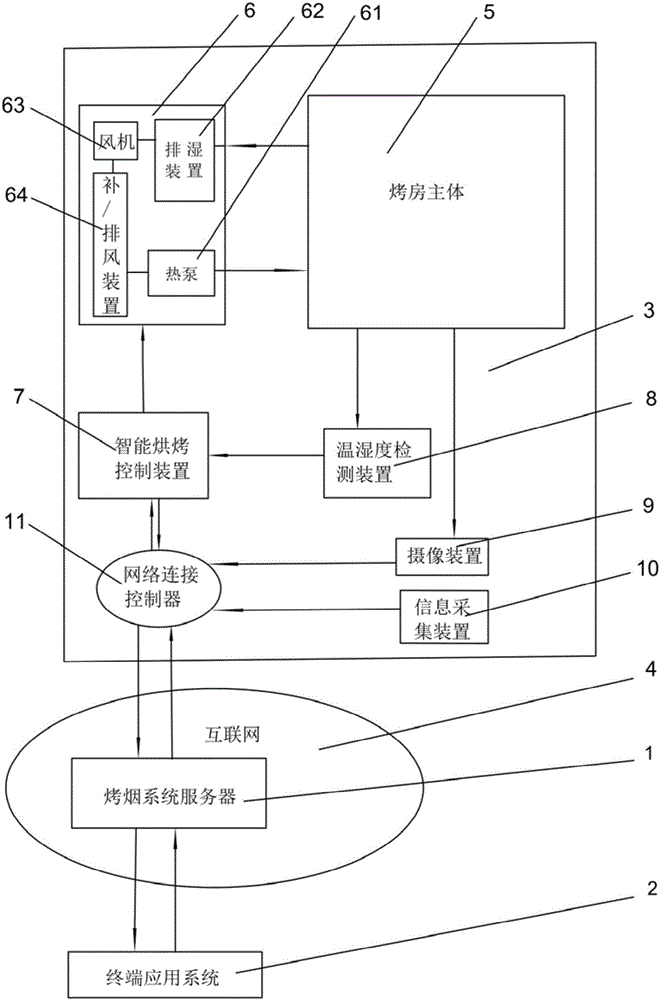

Method used

Image

Examples

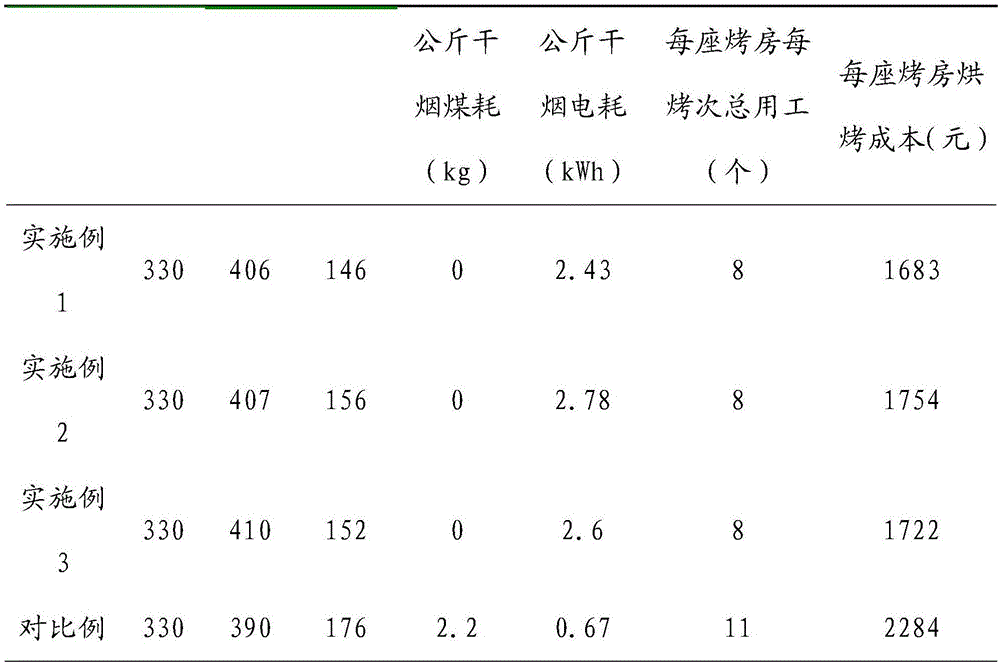

Embodiment 1

[0025] Example 1: Tobacco leaves in the middle of Cuibi No. 1 in Sanming, Fujian Province are baked in an intelligent flue-curing room 3. The steps of the curing process are as follows: Step 1: Arrange the mature fresh tobacco leaves in the conventional flue-curing room after weaving rods. The form is placed in a well-ventilated tobacco shed until the tobacco leaves are 30% yellow and slightly soft; in the second step, the dry bulb temperature is raised to 37.5°C at a rate of 1°C / h, and the wet bulb temperature is controlled at 36°C for 10 hours. , the fan speed is 1000r / min, so that the tobacco leaves are 60% yellow; in the third step, the dry bulb temperature is raised to 40°C at a rate of 0.5°C / h, and the wet bulb temperature is controlled at 37°C for 20h; the fan speed is controlled at 1200r / min , so that the tobacco leaves are 90% yellow and the tobacco leaves are pointed and curled; the fourth step is to increase the dry bulb temperature to 46°C at a speed of 0.5°C / h, whi...

Embodiment 2

[0026] Example 2: Tobacco leaves in the middle of Cuibi No. 1 in Sanming, Fujian Province are baked in an intelligent flue-curing room 3. The steps of the baking process are as follows: Step 1: Arrange the mature fresh tobacco leaves according to the conventional arrangement in the flue-curing room. The form is placed in a well-ventilated tobacco shed until the tobacco leaves are 30% yellow and slightly soft; in the second step, the dry bulb temperature is raised to 38.5°C at a rate of 1°C / h, and the wet bulb temperature is controlled at 37°C for 20 hours. , the fan speed is 1200r / min, and the tobacco leaves are 60% yellow; in the third step, the dry bulb temperature is raised to 42°C at a rate of 0.5°C / h, and the wet bulb temperature is controlled at 38°C for 30h; the fan speed is controlled at 1300r / min , until the tobacco leaves are 90% yellow and the tobacco leaves are hooked and curled; the fourth step is to increase the dry bulb temperature to 48°C at a speed of 0.5°C / h, ...

Embodiment 3

[0027] Example 3: Tobacco leaves in the middle of Cuibi No. 1 in Sanming, Fujian Province are baked in an intelligent flue-curing room 3. The steps of the baking process are as follows: Step 1: Arrange the ripe fresh tobacco leaves in a conventional flue-curing room after braiding the rods The form is placed in a well-ventilated tobacco shed until the tobacco leaves are 30% yellow and slightly soft; in the second step, the dry bulb temperature is raised to 38°C at a rate of 1°C / h, and the wet bulb temperature is controlled to 36.5°C. 12h, the fan speed is 1080r / min, and the tobacco leaves are 60% yellow; in the third step, the dry bulb temperature is raised to 41℃ at a rate of 0.5℃ / h, and the wet bulb temperature is controlled at 37.5℃ for 22h; the fan speed is controlled at 1260r / h Min, to make the tobacco leaves 90% yellow, and the tobacco leaves are hooked and curled; the fourth step is to increase the dry bulb temperature to 47°C at a speed of 0.5°C / h, while controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com