Method for recovering uranium from weak alkaline leaching solution with high chloride ion and high salinity

A technology with high salinity and weak alkalinity, applied in the field of uranium recovery, can solve the problem of low uranium concentration, and achieve the effects of increasing uranium concentration, simplifying existing processes, and reducing effluent process wastewater.

Active Publication Date: 2011-02-16

BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

) leaching, resulting in a low concentration of uranium in the leach solution, resulting in the resin working capacity and leaching qualified uranium concentration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0025] Qualified liquid is heated to boiling point (normally temperature is 102 ± 1 ° C), and maintained for 10 ~ 20min. then stir

[0029] The product is washed by leaching on the plate, and a small amount of fresh water is used to wash the sediment, and the washing tail water returns to the washing agent.

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

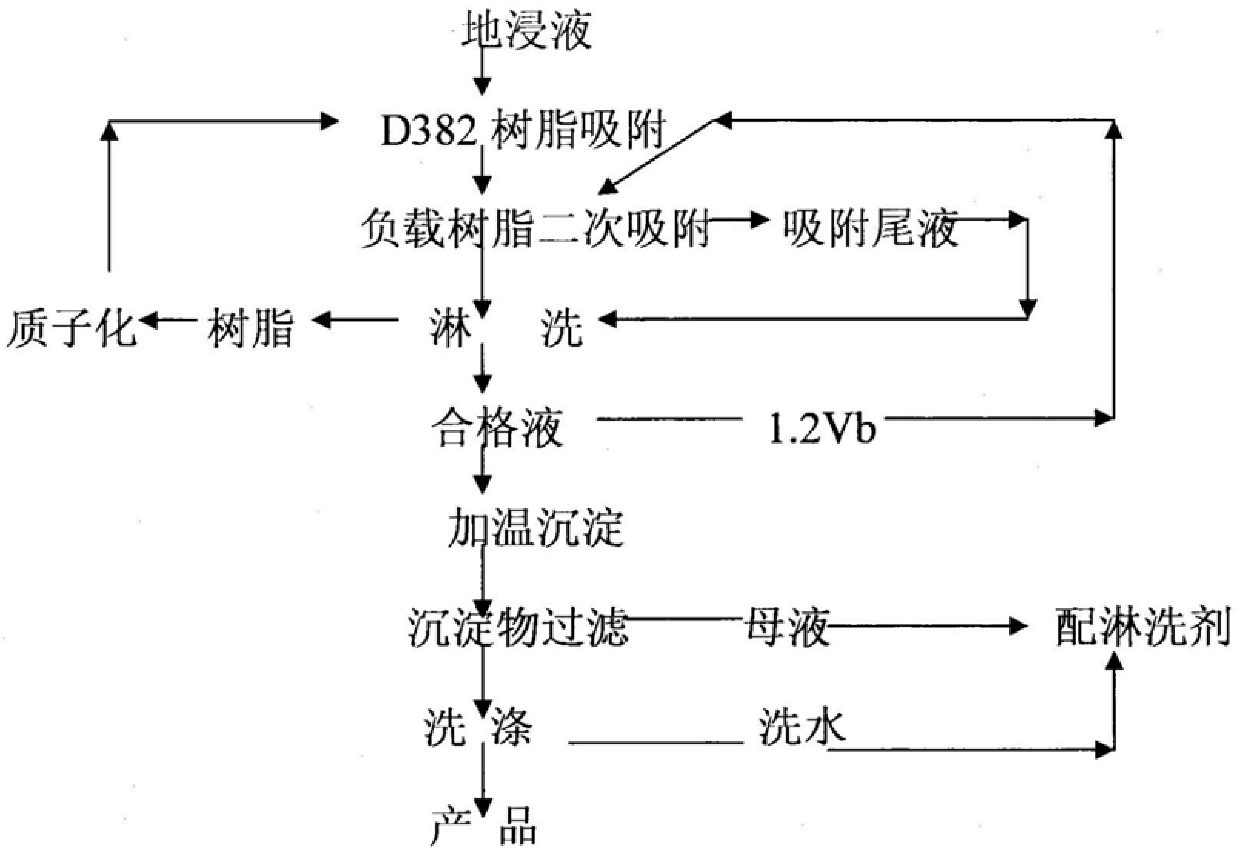

The invention belongs to the technical field of uranium ore water smelting technology, and specifically adopts anion exchange resin to adsorb D382, loaded resin for secondary adsorption (uranium-loaded resin absorbs uranium in the leaching qualified liquid), ammonium chloride plus sodium carbonate leaching It is a process for recovering uranium from the weakly alkaline leaching solution with high chlorine and high salinity by washing and heating precipitation. It effectively solves the problem of effectively adsorbing uranium from the weak alkaline leaching solution with high chloride ion and high salinity as high as 6g.L-1 and about 10g.L-1 salinity. Rinse the loaded resin with NH4Cl+Na2CO3 solution to obtain a satisfactory rinsing effect. The secondary adsorption of the loaded resin (the loaded resin is in contact with part of the eluting qualified solution) effectively increases the uranium concentration of the eluting qualified solution. After the eluting qualified solution is heated to drive off ammonium and carbon dioxide, uranium oxide precipitates are obtained. The precipitation process reduces the consumption of reagents and fresh water, simplifies the precipitation process, and at the same time obtains uranium products with good filtration and dehydration performance. The product obtained under the test conditions contains 79.96% uranium, 0.046% chloride ion and 2.91% sulfate radical.

Description

Method for recovering uranium from weakly alkaline leaching solution with high chloride ion and high salinity Technical field The invention belongs to the technical field of uranium ore water metallurgy, specifically with anion exchange resin adsorption, load tree Lipid secondary adsorption (resin loaded with uranium adsorbs uranium in the eluting qualified solution), chloride plus carbonate leaching, heating precipitation method from A process for recovering uranium from a weakly alkaline leaching solution with high chloride ions and high salinity. Background technique Uranium ore hydrometallurgy process usually adopts sulfuric acid solution or carbonate solution leaching, strongly basic anion exchange resin or amine Extraction agent separation, uranium enrichment, chloride or nitrate solution rinsing or stripping, sodium hydroxide precipitation, production of diuranate process. Since chloride or nitrate is an effective rinsing (back extraction) agent, the leaching s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B60/02C22B3/24C22B3/42

Inventor 王肇国牛玉清韩青涛

Owner BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com