A CNC deep-hole broaching machine for artillery barrel rifling and variable-section grooves for retracting rods

A technology of CNC deep hole broaching machine and gun barrel, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., which can solve the problems of high maintenance cost, general precision, and low productivity, and achieve Low maintenance costs, high safety, and high productivity

Active Publication Date: 2014-06-25

SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Summary of the invention For solving the problem that existing broaching machine structure is complex, productivity is low, precision is general, maintenance cost is high, the invention provides

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

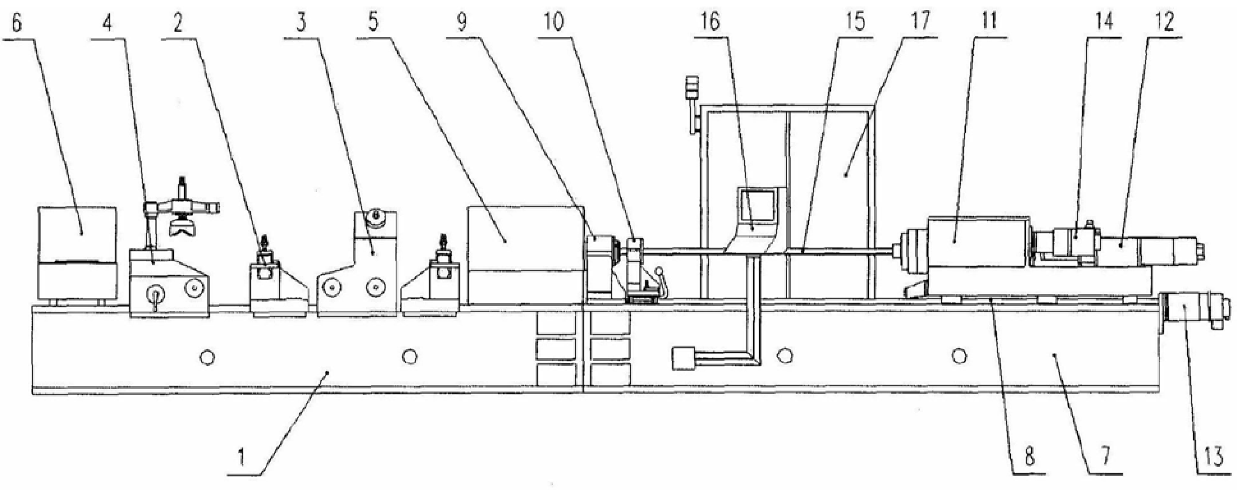

[0022] The workpiece bed 1 is also connected to the tool bar bed 7 for the support of the broaching parts of the workpiece.

[0025] The feed system 11 includes an X-axis feed mechanism 12, a Z-axis feed mechanism 13 and a C-axis feed mechanism 14. That

[0027] The operation box 16 is connected with an electric control cabinet 17 for installing a broaching machine numerical control module, a drive module and components.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of broaching machine devices, and in particular relates to a numerically controlled deep hole broaching machine used for gun barrel rifling and receding bar variable cross-section grooves, including a workpiece bed for positioning workpieces and supporting clamping components, and is also connected with The tool bar bed is used to support the broaching parts of the workpiece; the tool bar bed is connected with a roller linear guide, a fixed guide frame, and an operation box, and the roller linear guide is connected with a follow-up guide frame, a The feeding system controls the output tension and torque of the feeding system through the control system composed of the operation box and the electric control cabinet, and finally completes the broaching of the rifling of the gun barrel and the variable-section groove of the retracting rod through the broaching system. The broaching machine of the present invention has high precision, high productivity, high safety, good reliability and low maintenance cost.

Description

Technical field The invention belongs to broaching device technical field, be specifically related to a kind of for cannon barrel rifling and retreat rod variable section Groove CNC deep hole broaching machine. Background technique Traditional cannon barrel rifling and receding bar variable cross-section groove are processed using profiling broaching machine, and its mechanism is complicated, precise The degree can barely meet the requirements. In particular, the indexing function actually consists of fitting the helical line or the expanded line of other curves by the template, and then The main shaft indexing is carried out by the rack and pinion pair or the worm gear pair. Firstly, the mechanism of the template is relatively complicated and takes up a large space. Often when processing and replacing products, a large number of tedious calculations and adjustments are required, and the accuracy is not easy to guarantee; secondly, the rack and pinion The transmissi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23B41/02

Inventor 陈昌金石航飞尹健张天佑刘玲景富军龚运环王新科谭胜龙何佳林

Owner SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com