Low carbon charger

A charger and charging unit technology, applied in the electronic field, can solve the problems of increasing the overall scrapping of chargers, fragile charging tubes, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

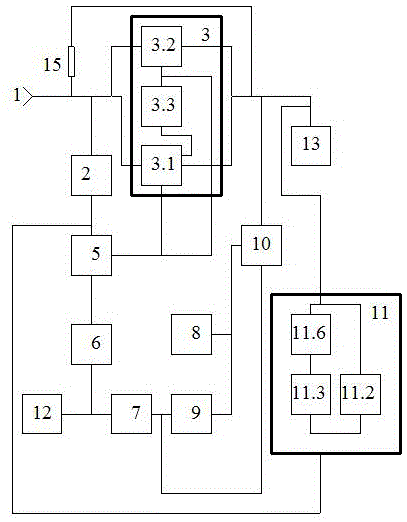

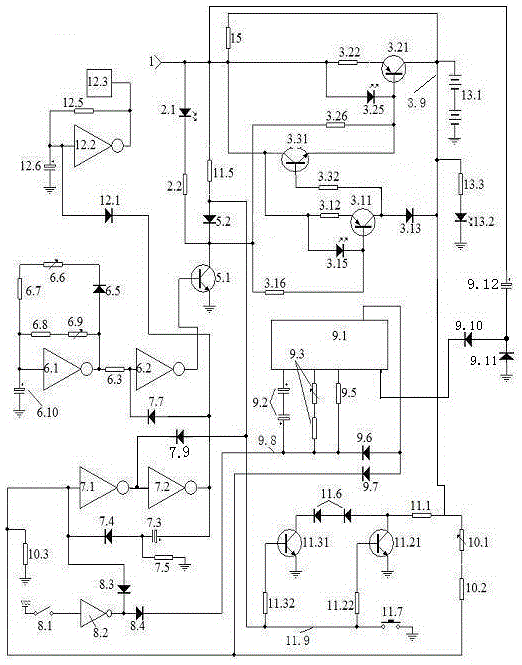

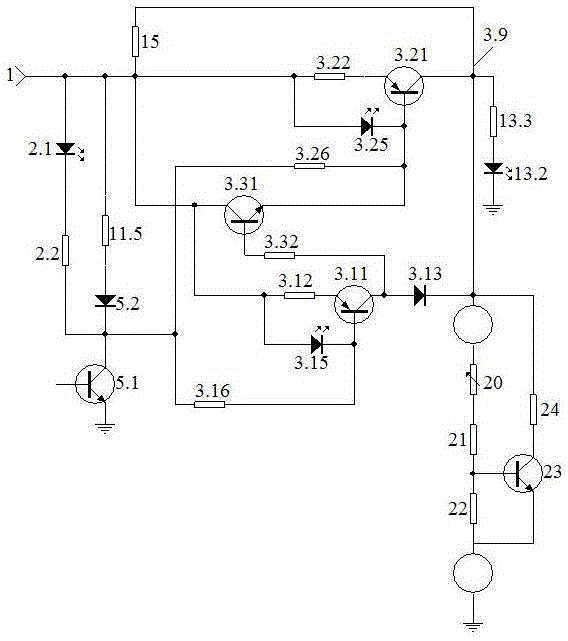

[0115] figure 1 figure 2 An example of a low-carbon charger implementation is given, image 3 and Figure 4 Example of detection map in implementation.

[0116] 1. Select components: The inverters in this method are all welded by Schmidt circuit, and the discharge resistor is a high-power resistor.

[0117] 2. Make the circuit control board, welding components: connect figure 2 Make the circuit control board according to the schematic diagram, connect figure 2 Schematic of soldered components.

[0118] 3. Power on, check and debug.

[0119] Check that the welding is correct, and then conduct power-on inspection and debugging.

[0120] 1. Check the constant current source part.

[0121] Such as image 3 Weld a dummy load as shown, connect a triode to form an adjustable voltage regulator analog circuit, and replace the charged battery as a dummy load. Use the ammeter of the multimeter to string the red pen in the dummy load, or connect the red pen to the anode of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com