Liquid injection head of polymer battery electrolyte

A technology of electrolyte and polymer, which is applied in the manufacture of battery components, non-aqueous electrolyte storage batteries, and electrolyte storage batteries. It can solve the problems of dust entering the electrolyte, secondary pollution, and exposure of the electrolyte to avoid long-term contact. , Easy to replace filter paper, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

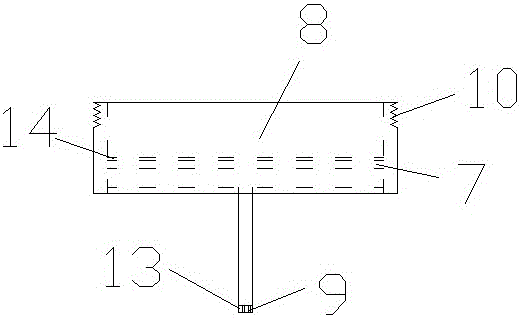

[0012] The technical solution of the present invention is described in detail in conjunction with the accompanying drawings. A polymer battery electrolyte injection head includes an upper cover 1 and a main body 2 made of polyethylene or polypropylene, and the upper cover 1 is provided with a first cavity inside. 11. The surface of the first cavity 11 is provided with an internal thread 5, the upper surface of the upper cover 1 is fixedly provided with a gas pressure tube 4 and a liquid injection tube 3 respectively communicating with the first cavity 11, and the upper side surface of the main body 2 is provided with a The external thread 10 matched with the internal thread 5 is internally provided with a second cavity 8 communicating with the first cavity 11, and the inside of the second cavity 8 is provided with a circular electrolyte filter screen 7 having the same cross-sectional size as the same. The upper surface of the electrolyte filter 7 is covered with a filter paper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com