Method for detecting low sub surface damages of rigid brittle optical material

A sub-surface damage and optical material technology, applied in the direction of optical testing flaws/defects, using optical devices, measuring devices, etc., to achieve the effects of simple structure of testing instruments, high accuracy of testing results, and simple testing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] The low subsurface damage detection method of hard and brittle optical materials in this embodiment includes the following steps:

[0029] (1) Preparation of test equipment

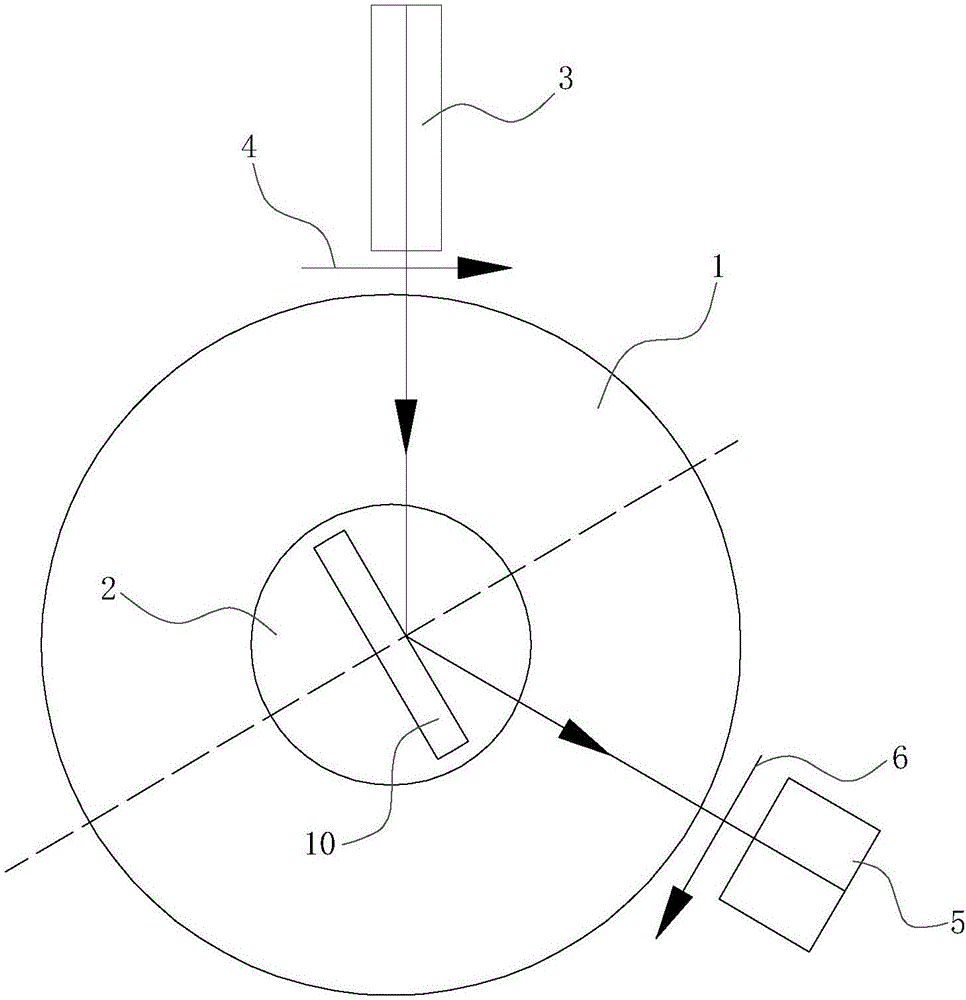

[0030] Such as figure 1 As shown, the test instrument comprises a dial 1, an object stage 2, a laser 3, a first polarizer 4, a light intensity meter 5 and a second polarizer 6, and the dial 1 can be rotated on a horizontal platform. The edge of the upper surface of the disk 1 has scale lines arranged along the circumferential direction, and the stage 2 is shaped as a disc and is arranged in the middle of the dial 2 to fix the sample 10 to be tested. The stage 2 is the same as the dial 1. The shaft is arranged and can rotate with the rotation of the dial 1 .

[0031] The laser 3 is arranged near the edge of the dial 1, and the incident light emitted by the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com