A convenient cleaning grille lamp

A grille light and cleaning technology, which is applied to the parts of lighting devices, lighting auxiliary devices, lighting and heating equipment, etc., can solve the problems of inconvenient cleaning of grille lights, inability to achieve good cleaning, and inadequate cleaning of lamps and lanterns. , to achieve the effect of convenient and fast cleaning, cost saving and increasing practical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

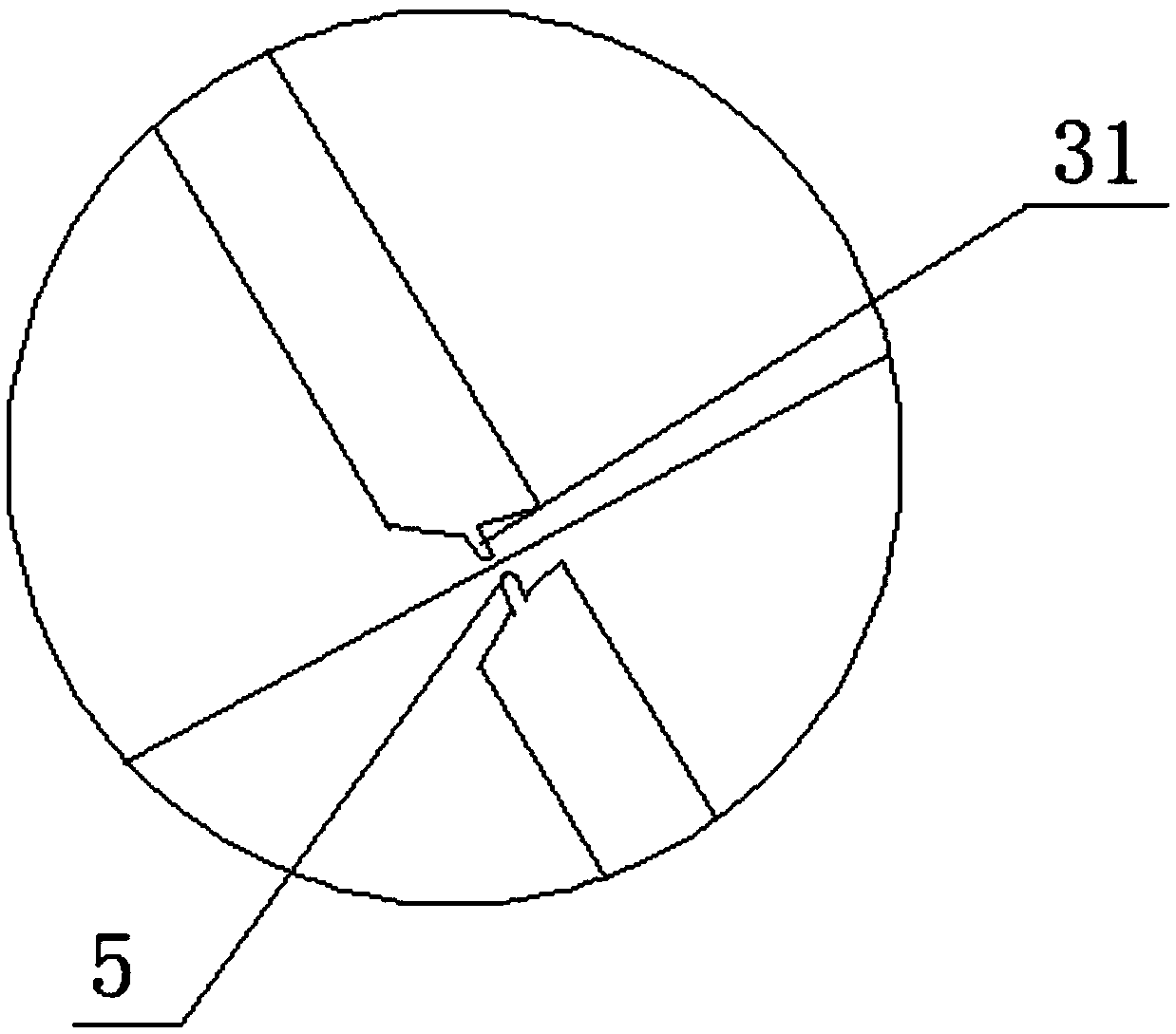

[0023] Such as figure 1 As shown, a convenient and clean grill lamp includes a lamp panel 1, a bulb 2, and a grille 3. The lamp panel 1 is provided with a bulb partition 4, and both sides of the bulb partition 4 and the lamp panel 1 are provided with Circular through holes 5, the two ends of the grid 3 are provided with rotating shafts 31, the rotating shafts 31 snap into the through holes 5 of the bulb partition 4 and the lamp panel 1, the number of through holes 5 is the same as that of the grid 3 The rotation axes 31 have the same number and corresponding positions, and the arcs at both ends of the grille 3 correspond to the arcs between the grille 3 and the inner side of the lamp panel 1 . The remaining length of the rotating shaft 31 after passing through the through hole 5 is 3mm, and the diameter of the rotating shaft 31 is 3mm. The grille 3 and the rotating shaft 31 are integrally formed, and the grille 3 and the rotating shaft 31 can be removed. The material of the g...

Embodiment 2

[0025] On the basis of Embodiment 1, the materials of the grid 3 and the rotating shaft 31 are not directly made of matte alumina material, but after the common metal composite material is used, a layer of fir pulp layer 6 is coated on the surface, and finally the The surface of the fir tree pulp layer is coated with a layer of matt aluminum oxide material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com