Composite processing device and composite processing method

A composite processing and processing area technology, which is applied in the direction of additive processing, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the processing area cannot be visually confirmed, and achieve the effect of easy visual confirmation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

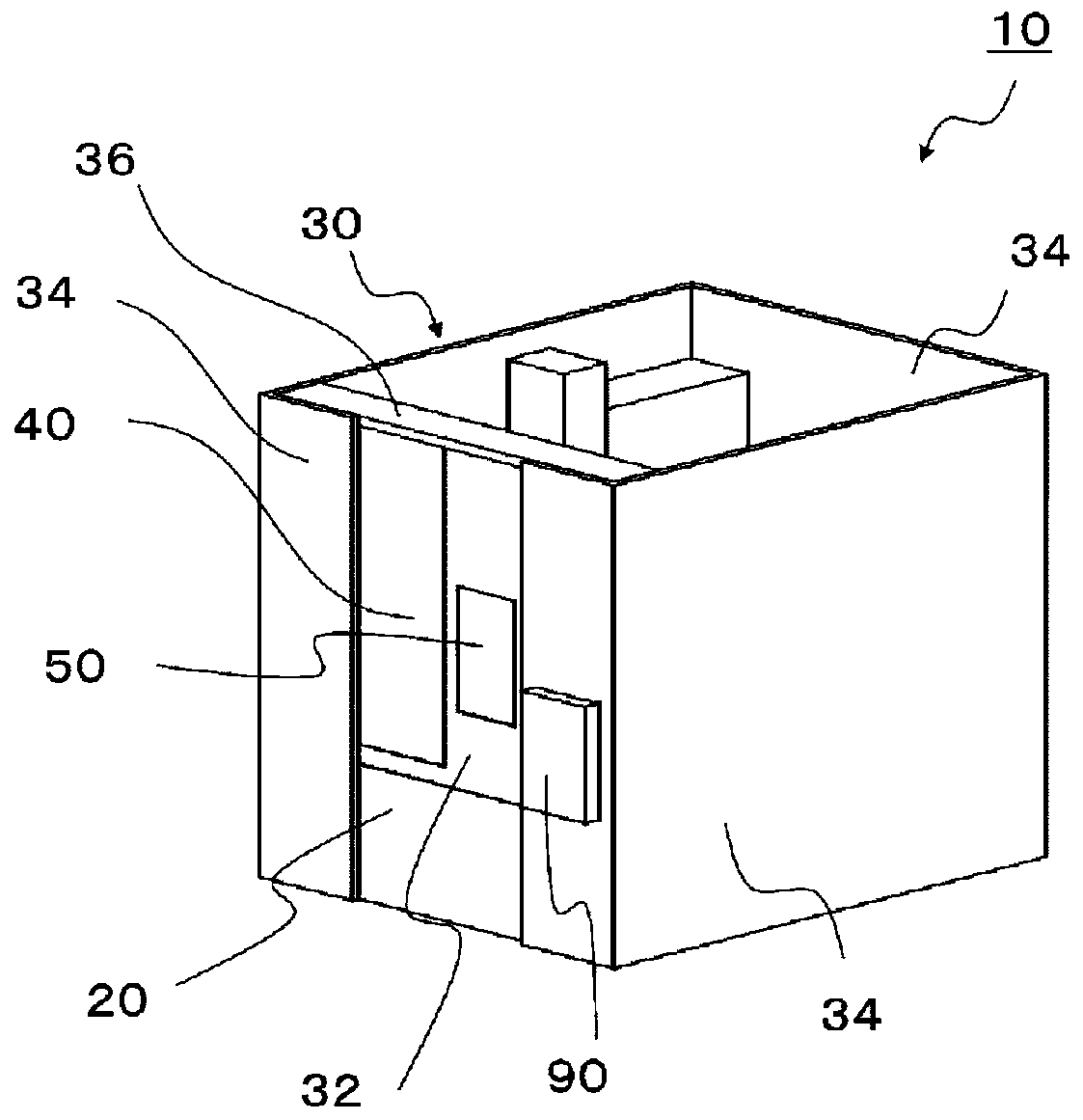

[0052] use figure 1 5 to 5 illustrate the combined processing device 10 according to the first embodiment of the present invention.

[0053] figure 1 is an external view of the combined processing device 10 of the first embodiment, figure 2It is a schematic diagram showing the interior of the composite processing device 10 without a cover. Such as figure 1 and figure 2 As shown, the composite processing device 10 according to the first embodiment of the present invention includes: an additive manufacturing unit 12, which irradiates energy on the workpiece W in the processing area to perform additive manufacturing; a cutting processing unit 14, which performs cutting processing on the workpiece W in the processing area. the cover part 30 covering the processing area; Here, the processing area refers to an area where additive manufacturing or cutting processing is performed on the workpiece W by the hybrid machining device 10 .

[0054] The cover part 30 includes: a door...

no. 2 approach >

[0073]A composite machining device 110 according to a second embodiment of the present invention will be described with reference to FIG. 6 . In the first embodiment, the light-shielding filter 50 is arranged on the front cover 32 fixed to the composite processing apparatus 10. As shown in FIG. In contrast, the second embodiment is different in that one light-shielding filter 150 is arranged on each of the door portions 140 arranged to be openable and closable.

[0074] In addition, the structure of the machine tool required for additive manufacturing or cutting processing itself is different from the figure 2 The structure described in the first embodiment shown is the same, and therefore description thereof will be omitted here.

[0075] FIG. 6 is a schematic diagram of a composite machining device 110 according to a second embodiment of the present invention. Figure 6A is an external view of the composite processing device 110 in a state where the door 140 is closed, ...

no. 3 approach >

[0087] A composite machining device 210 according to a third embodiment of the present invention will be described with reference to FIGS. 7 to 9 . In the second embodiment, one light-shielding filter 150 is disposed on each of the double-opening door portions 140 . In contrast, the third embodiment is different in that a plurality of light-shielding filters 250 are respectively arranged on the double-opening door portion 240 .

[0088] In addition, the structure of the machine tool required for additive manufacturing or cutting processing itself is different from the figure 2 The structure described in the first embodiment shown is the same, and therefore description thereof will be omitted here.

[0089] FIG. 7 is a schematic diagram of a composite machining device 210 according to a third embodiment of the present invention. Figure 7A is an external view of the composite processing device 210 in a state where the door 240 is closed, Figure 7B It is a three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com