S-CO2 cycle waste-heat utilizing system for EGR cooler of marine low-speed diesel engine

An EGR cooler, S-CO2 technology, applied in the direction of charging system, exhaust gas recirculation, machine/engine, etc., can solve the problems of diesel engine economical deterioration, fuel consumption increase, diesel engine combustion deterioration, etc., to achieve compact structure, The effect of solving energy consumption and reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

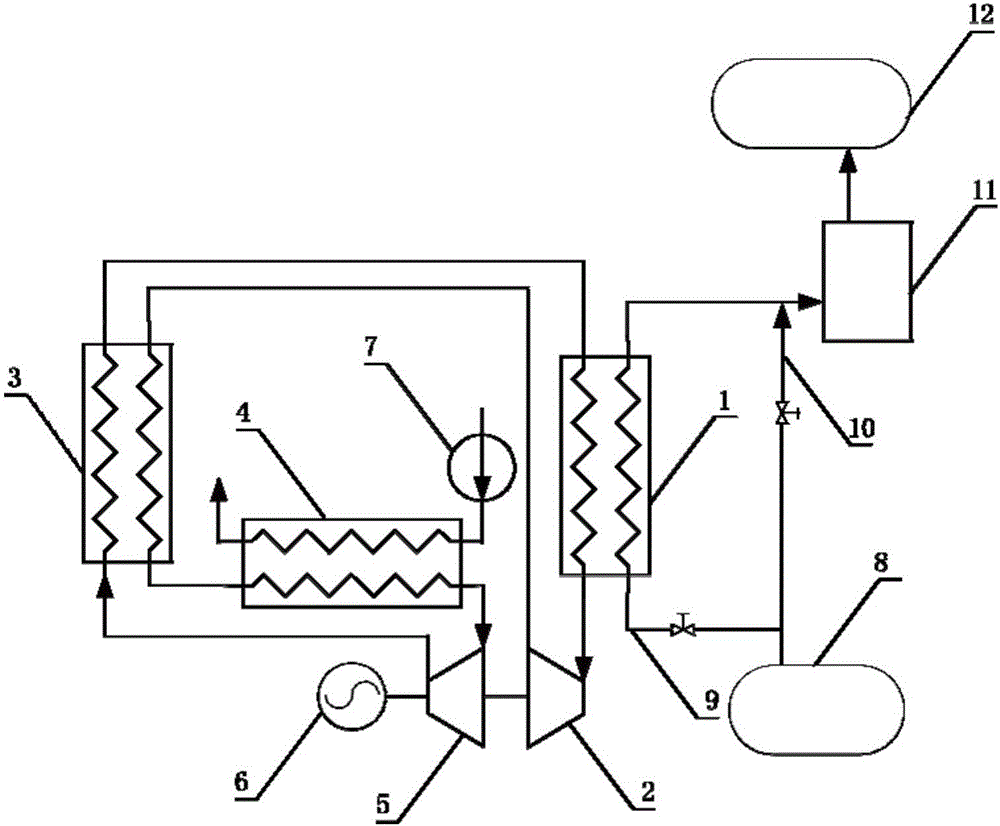

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0013] to combine figure 1 , the present invention consists of S-CO 2 circuit and EGR circuit. where S-CO 2 The circuit is composed of working medium side 1 of EGR cooler, expander 2, high temperature side of regenerator 3, working medium side of cooler 4, compressor 5, and low temperature side of regenerator 3, connected in sequence. where S-CO 2 The circuit also includes a generator 6 coaxially connected with the expander 2 and a cooling water pump 7 providing cooling water for the cooler 4 . The EGR circuit is composed of an exhaust header 8, a main flue gas pipe 9, a flue gas side of an EGR cooler 1, a main EGR device 11 and an intake header 12 connected in sequence. Wherein the EGR circuit also includes a flue gas bypass pipe 10 for bypassing.

[0014] The exhaust gas discharged from the marine diesel engine exhaust header 8 first enters the EGR cooler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com