Paper pulp material pulverizing device

A technology of grinding and pulping, applied in papermaking, fiber raw materials, raw material separation, etc., can solve the problems that the grass cannot be evenly distributed, the grass cannot be rolled, and the length and uniformity of the fibers cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

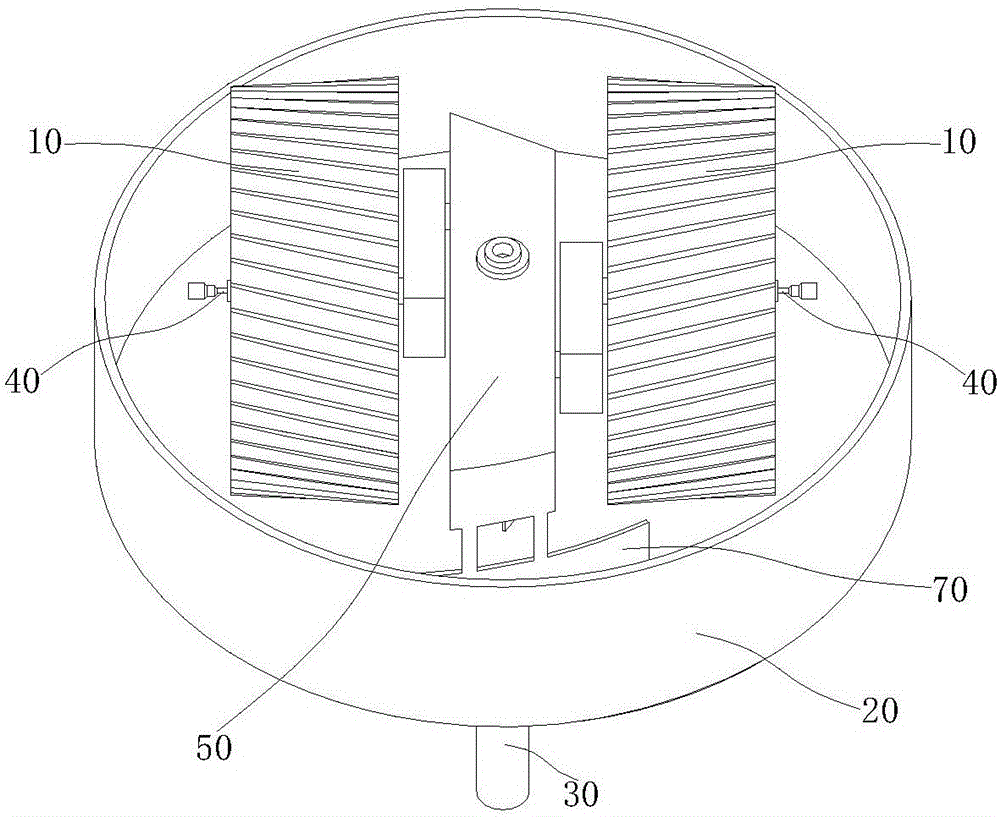

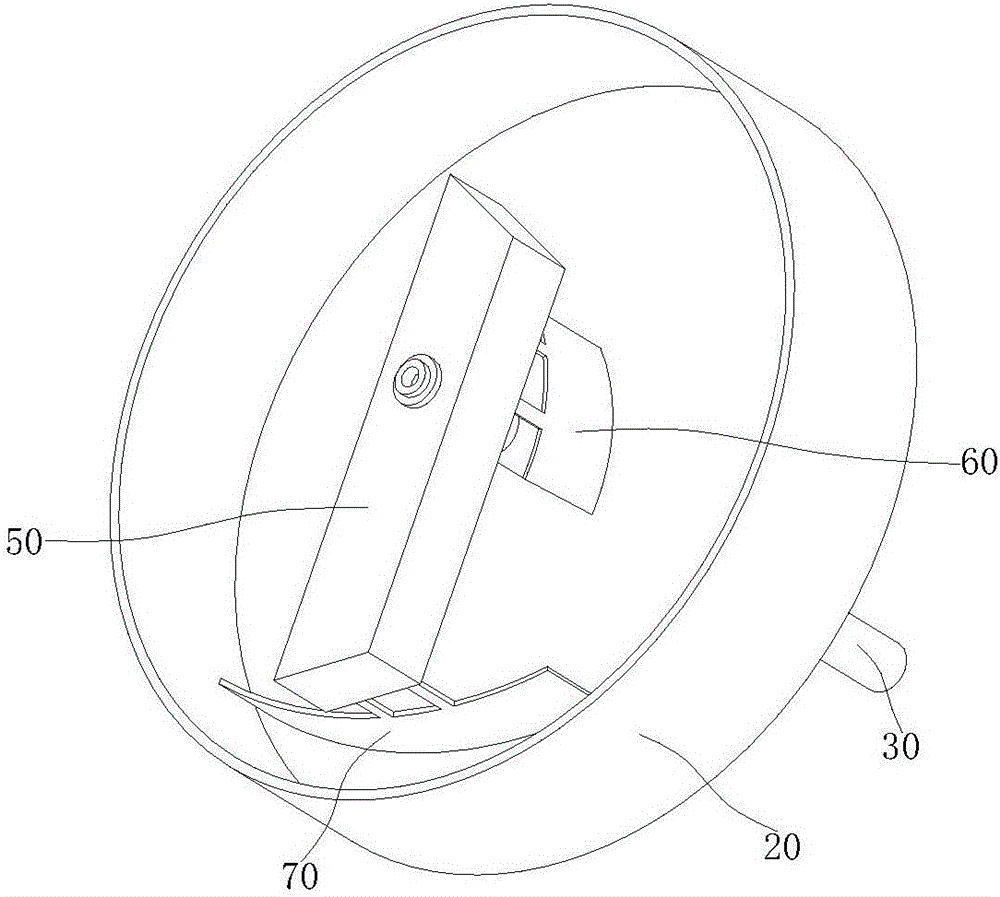

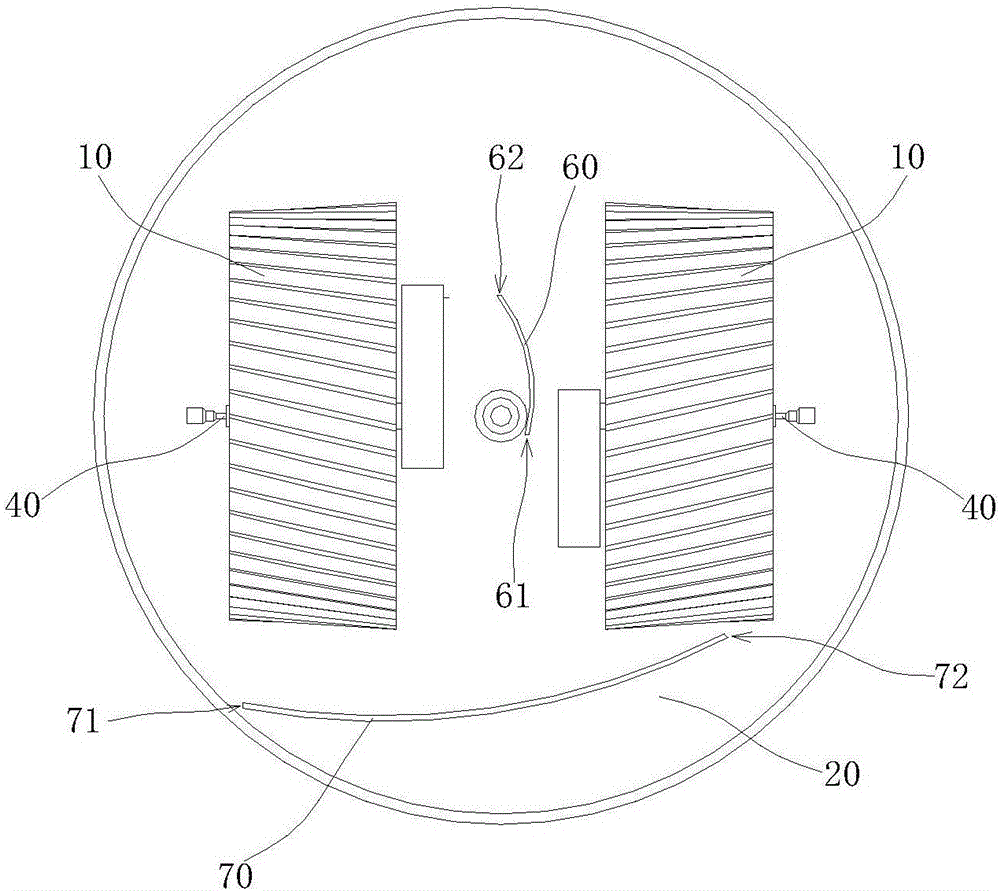

[0010] combine Figure 1~4 The present invention is described further:

[0011] A paper pulp crushing device, comprising a stone mill 10, the mouth of the cylinder 20 is upward, the middle of the cylinder 20 is provided with a vertically arranged main shaft 30, and the main shaft 30 is connected to the stone mill 10 via a flat stone mill shaft 40 The roller surface of the stone mill 10 and the inner cylinder bottom of the mill cylinder 20 form a rolling fit, the main shaft 30 is provided with a cross bar 50, the middle part of the cross bar 50 is fixedly connected with the main shaft 30 in the circumferential direction, and the cross bar 50 The bottom is provided with inner and outer scrapers 60, 70, and when the inner and outer scrapers 60, 70 rotate with the main shaft 30, the grass scraper is pushed to the rolling path of the stone mill 10. The main rotating shaft 30 is connected with the driving mechanism, and the stone mill 10 revolves around the main rotating shaft 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com