Rose essential oil squeezing and extracting device

A technology for rose essential oil and extraction equipment, which is applied in the directions of essential oil/spice, fat production, etc., can solve the problems of low essential oil obtaining rate and cumbersome production process, and achieve the effects of preventing pollution and improving the essential oil obtaining rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

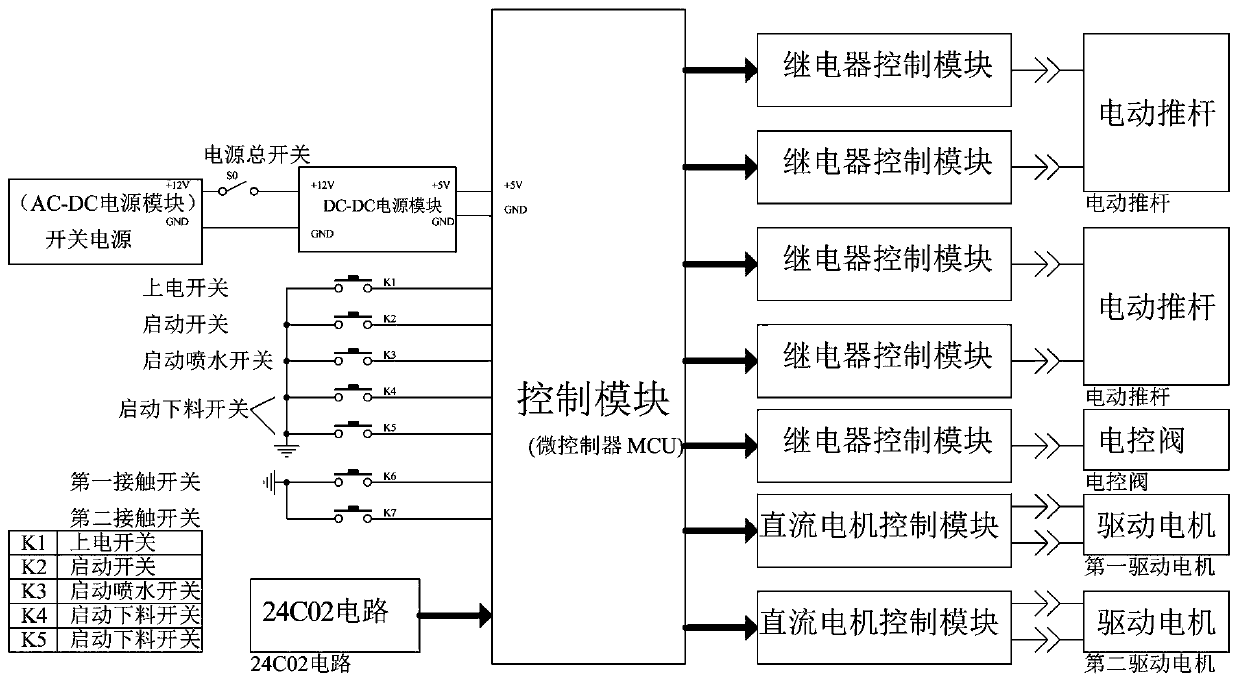

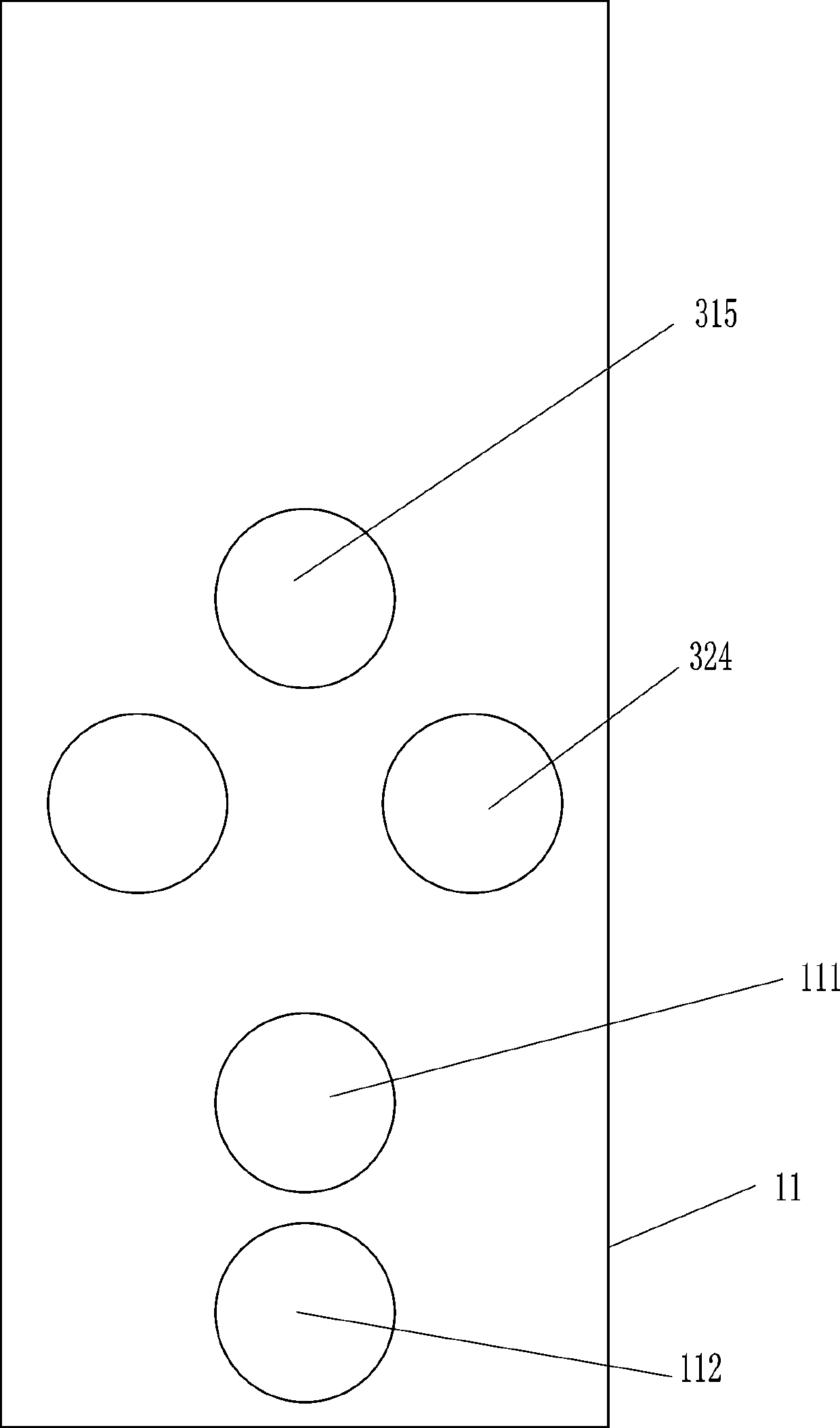

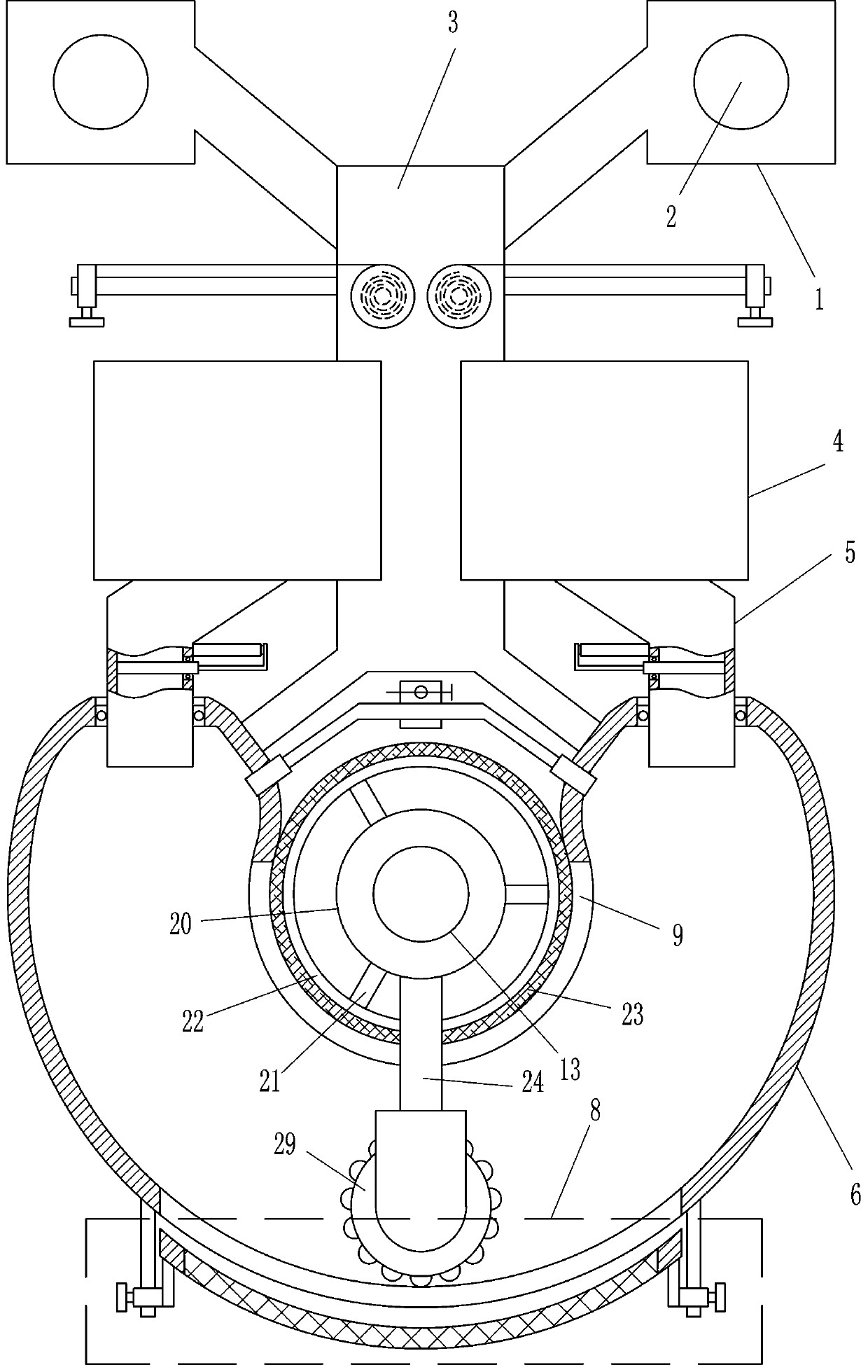

[0032] A kind of rose essential oil pressing extraction equipment, such as Figure 1-6 As shown, it includes wall hanging board 1, mounting screw 2, N-type mounting frame 3, material box 4, feeding pipe 5, processing box 6, observation glass 7, unloading device 8, connecting frame 10, control box 11, upper Electric switch 111, start switch 112, first bearing seat 12, first rotating rod 13, first gear 14, first drive motor 15, second gear 16, contact block 17, first contact switch 18, second contact switch 19. Mounting plate 20, bracket 21, rotating ring 22, rubber ring 23, mounting rod 24, fixed frame 25, second bearing seat 27, second driving motor 28, second rotating rod 281 and rolling wheel 29, on the wall The wall hanging board 1 is installed by two mounting screws 2, and the middle part of the lower side of the wall hanging board 1 is provided with an N-type mounting frame 3, and the left and right sides of the middle part of the N-type mounting frame 3 are equipped with...

Embodiment 2

[0035] On the basis of Example 1, such as Figure 6 As shown, the unloading device 8 includes a first guide rail 82, a first guide sleeve 83, a first fastening bolt 84, a connecting block 85, a first baffle plate 86 and a screen plate 87, and the bottom of the processing box 6 has a blanking Hole 81, the left and right sides of processing box 6 bottoms are connected with first guide rail 82, and two first guide rails 82 are positioned at the left and right sides of blanking hole 81, and first guide rail 82 is provided with the first guide sleeve 83 slidingly, the first guide rail 82 The outer sides of a guide sleeve 83 are all threadedly connected with first fastening bolts 84, and the first fastening bolts 84 are all in contact with the first guide rail 82, and the inner sides of the first guide sleeve 83 are provided with connecting blocks 85, between the two connecting blocks 85 A first baffle plate 86 is arranged between, and a filter screen plate 87 is embedded on the fir...

Embodiment 3

[0040] On the basis of Example 1 and Example 2, as Figure 4 and Figure 10 Shown, also comprise shower nozzle 311, connecting pipe 312, external water pipe 313, electric control valve 314 and start water spray switch 315, the left and right sides of processing box 6 tops are all provided with shower nozzle 311, connect between left and right two shower nozzles 311 Connecting pipe 312 is arranged, and connecting pipe 312 middle part rear side is connected with external water pipe 313, and external water pipe 313 is provided with electric control valve 314, and control box 11 front side top is provided with start water spray switch 315.

[0041] In order to make the rose petals fully wetted by water so as to better extract the rose essential oil, it is necessary to add an appropriate amount of distilled water into the processing box 6 . The staff can connect the external water pipe 313 to the water delivery interface in advance. When distilled water needs to be added to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com