Regenerative garbage pyrolysis power generation system and method thereof

A regenerative and garbage technology, which is applied in the direction of combustion method, special form of dry distillation, combined combustion mitigation, etc., can solve the problems of complex process, high cost, multi-energy, etc., and achieve simple process, high production efficiency and reasonable control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

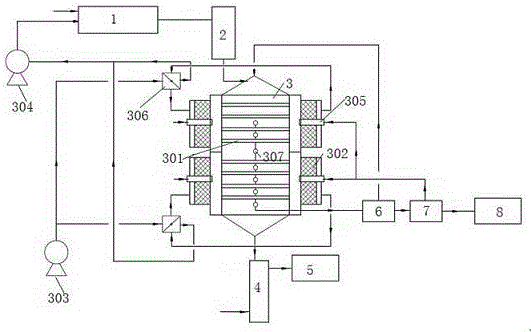

Image

Examples

Embodiment 1

[0073] Use the regenerative garbage pyrolysis reaction system to process the garbage. After the garbage is crushed, the particle size range is 6mm-200mm, and the pyrolysis residence time is 60 minutes. The analysis data, process operation parameters and material balance of the garbage are shown in the table. 1-Table 3. The biochar yield obtained from Table 3 was as high as 45.6%.

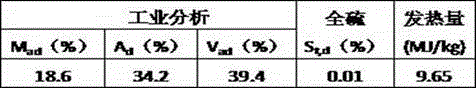

[0074] Table 1: Garbage analysis data

[0075]

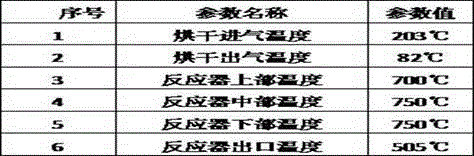

[0076] Table 2: Process operating parameters

[0077]

[0078] Table 3: Basic parameter table

[0079]

[0080] In the description of the present invention, it should be understood that the terms "first" and "second" are used for description purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features. Thus, a feature defined as "first" and "second" may explicitly or implicitly include one or more of these features.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com