Building interior decoration plate and production method thereof

A technology of building interior and decorative panels, which is applied in the field of building materials, can solve environmental pollution and other problems, and achieve the effects of good flame retardancy, not easy to delaminate and crack, and good overall compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A building interior panel, comprising a surface layer, a core layer and a bottom layer, the surface layer and / or the bottom layer is a decorative layer, the core layer is a support layer, the surface layer and the bottom layer are bonded to the surface and the bottom surface of the core layer, and the building interior panel is according to Prepared by the following method:

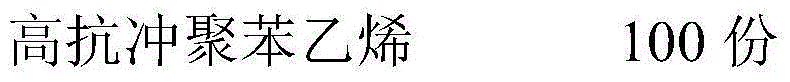

[0043] (1) 100 parts of high-impact polystyrene, 20 parts of carbonizing agent, 10 parts of catalyzer, 5 parts of blowing agent, 0.5 part of antioxidant are mixed homogeneously, add melt blending and extrude into sheet in the extruder, Then the embossing machine is used to emboss the decorative pattern on the surface to obtain the surface layer and the bottom layer;

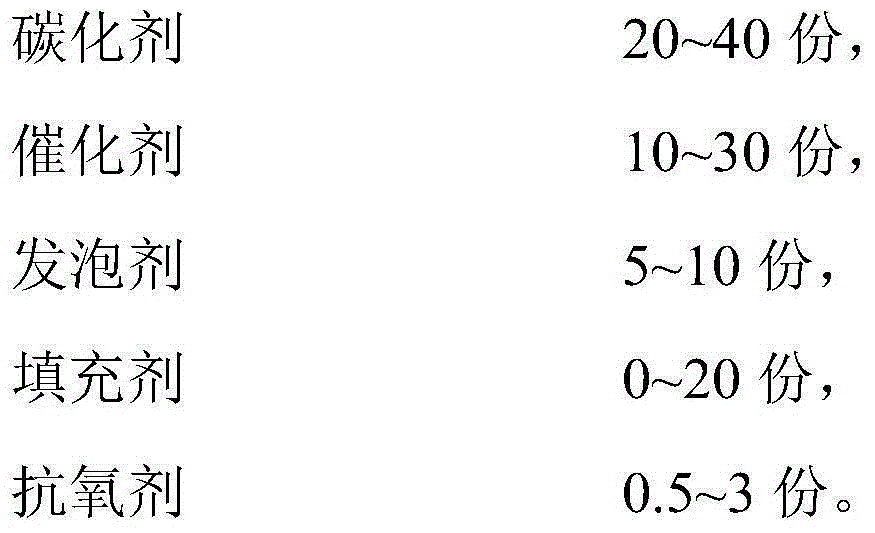

[0044] (II) Prepare the adhesive according to the following steps: (1) weigh 100 parts of polystyrene by weight, 2 parts of maleic anhydride, 40 parts of carbonizing agent, 30 parts of catalyst, 10 parts of foaming agent, and 2 parts ...

Embodiment 2

[0049] A building interior panel, comprising a surface layer, a core layer and a bottom layer, the surface layer and / or the bottom layer is a decorative layer, the core layer is a support layer, the surface layer and the bottom layer are bonded to the surface and the bottom surface of the core layer, and the building interior panel is according to Prepared by the following method:

[0050] (1) 100 parts of high-impact polystyrene, 40 parts of carbonizing agent, 30 parts of catalyst, 10 parts of foaming agent, 20 parts of filler, and 3 parts of antioxidant are mixed uniformly, and melt blending is added in the extruder and extruded It is made into a sheet, and then the decorative pattern is pressed on the surface by an embossing machine to obtain the surface layer and the bottom layer;

[0051](II) prepare the adhesive according to the following steps: (1) weigh 100 parts of polystyrene by weight, 6 parts of maleic anhydride, 60 parts of carbonizing agent, 50 parts of catalyst,...

Embodiment 3

[0056] A building interior panel, comprising a surface layer, a core layer and a bottom layer, the surface layer and / or the bottom layer is a decorative layer, the core layer is a support layer, the surface layer and the bottom layer are bonded to the surface and the bottom surface of the core layer, and the building interior panel is according to Prepared by the following method:

[0057] (1) 100 parts of high-impact polystyrene, 30 parts of carbonizing agent, 30 parts of catalyst, 7 parts of foaming agent, 10 parts of filler, and 1.5 parts of antioxidant are mixed uniformly, and melt blending is added in the extruder and extruded It is made into a sheet, and then the decorative pattern is pressed on the surface by an embossing machine to obtain the surface layer and the bottom layer;

[0058] (II) Prepare the adhesive according to the following steps: (1) weigh 100 parts of polystyrene by weight, 4 parts of maleic anhydride, 50 parts of carbonizing agent, 40 parts of catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com