A kind of persistent hydrophilic silicone oil and preparation method thereof

A hydrophilic silicone oil, long-lasting technology, applied in plant fiber, fiber treatment, textiles and paper making, etc., can solve the problems of affecting coloring effect, sulfur dye particle detachment, roughness, etc., to improve hydrophilicity and washability, improve Effect of chemical stability and durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

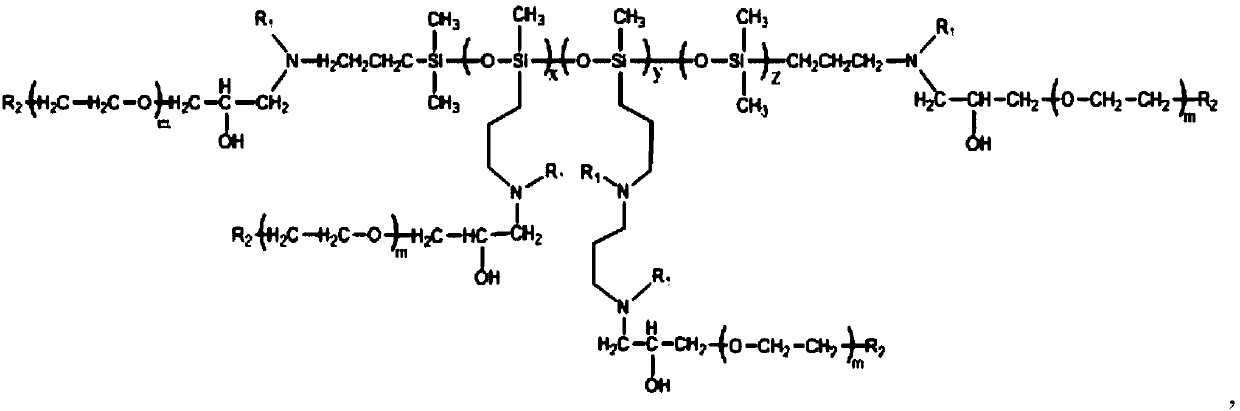

[0046] The persistent hydrophilic silicone oil of the present invention comprises side chain-terminal aminosilane with general formula A and single-end epoxy polyether with general formula B, and the molar ratio of the above-mentioned component content is: side chain-terminal aminosilane: single-terminal The ratio of epoxy polyether is 1:4, and the above components are reacted in an alkaline environment to obtain the structural formula:

[0047]

[0048] Where x is 10, y is 10, z is 200, m is 20; R1 is -CH 3 ; R2 is -OCH 3 .

[0049] The structural formula of the side chain-terminated aminosilane of general formula A is:

[0050] where x is 10, y is 10 and z is 200.

[0051] The structural formula of the single-ended epoxy polyether of general formula B is:

[0052] Where R2 is -OCH 3 , m is 20. The molar ratio of the amino group and the epoxyethyl group in the structural formula obtained from the reaction is 1:1.

[0053] The preparation method of persistent hyd...

Embodiment 2

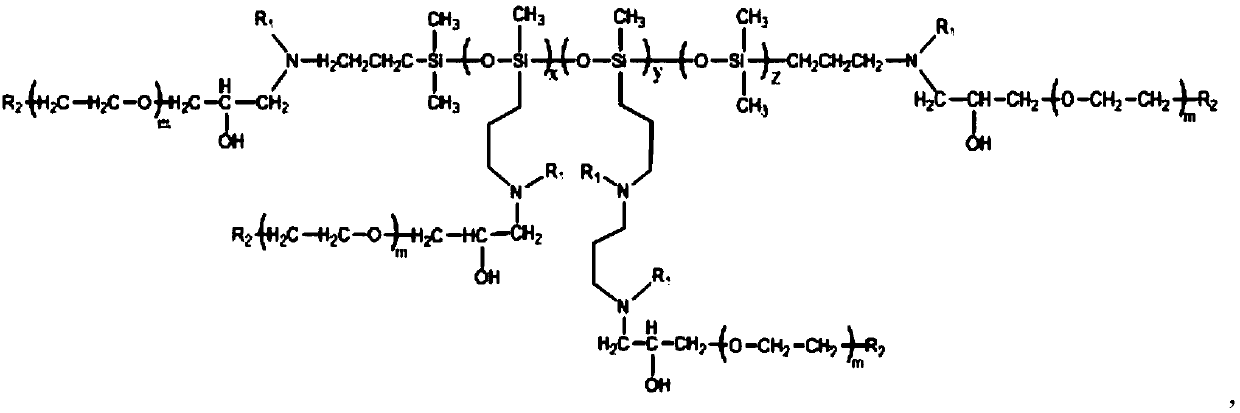

[0061] The persistent hydrophilic silicone oil of the present invention comprises side chain-terminal aminosilane with general formula A and single-end epoxy polyether with general formula B, and the molar ratio of the above-mentioned component content is: side chain-terminal aminosilane: single-terminal The ratio of epoxy polyether is 1:8, and the above components are reacted in an alkaline environment to obtain the structural formula:

[0062]

[0063] Where x is 0, y is 1, z is 10, m is 5; R1 is -CH 2 CH 2 —; R2 is — CH 3 .

[0064] The structural formula of the side chain-terminated aminosilane of general formula A is:

[0065] where x is 0, y is 1, and z is 10.

[0066] The structural formula of the single-ended epoxy polyether of general formula B is:

[0067] Where R2 is -CH 3 , m is 5. The molar ratio of amino groups and epoxyethyl groups in the structural formula obtained from the reaction is 1:2.

[0068] The preparation method of persistent hydrophili...

Embodiment 3

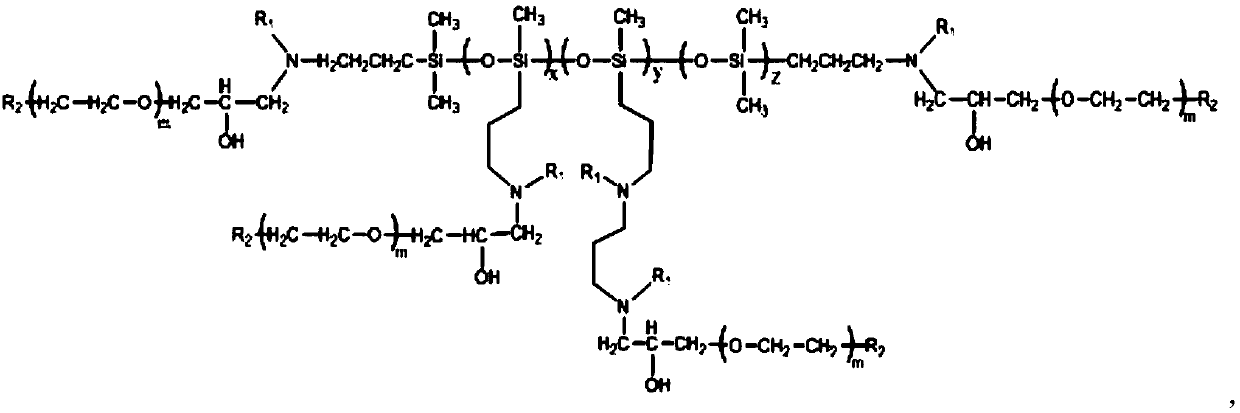

[0076] The persistent hydrophilic silicone oil of the present invention comprises a side chain-terminal aminosilane with general formula A and a single-end epoxy polyether with general formula B, and the molar ratio of the above-mentioned component content is: side chain-terminal aminosilane: single-terminal The ratio of epoxy polyether is 1:5, and the above components are reacted in an alkaline environment to obtain the structural formula:

[0077]

[0078] Wherein x is 3, y is 4, z is 50, m is 9; R1 is -H; R2 is -CH 2 CH 3 .

[0079] The structural formula of the side chain-terminated aminosilane of general formula A is:

[0080] Where x is 3, y is 4, and z is 50.

[0081] The structural formula of the single-ended epoxy polyether of general formula B is:

[0082] Where R2 is -CH 2 CH 3 , m is 9. The molar ratio of the amino group and the epoxyethyl group in the structural formula obtained from the reaction is 1:1.

[0083] The preparation method of persistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com