Mineral particle swirling flow pneumatic conveying system

A pneumatic conveying system and mineral particle technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as difficulty in adapting to the diversity of mineral particles, inability to realize swirl replenishment, and difficult adjustment of swirl intensity, etc. Achieve the effect of reducing the critical conveying speed, changing the speed, and reducing particle breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

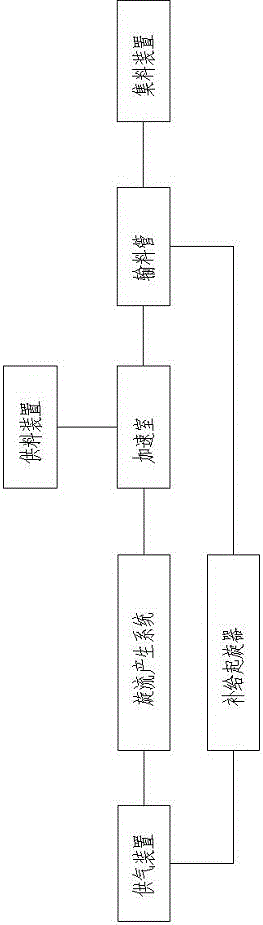

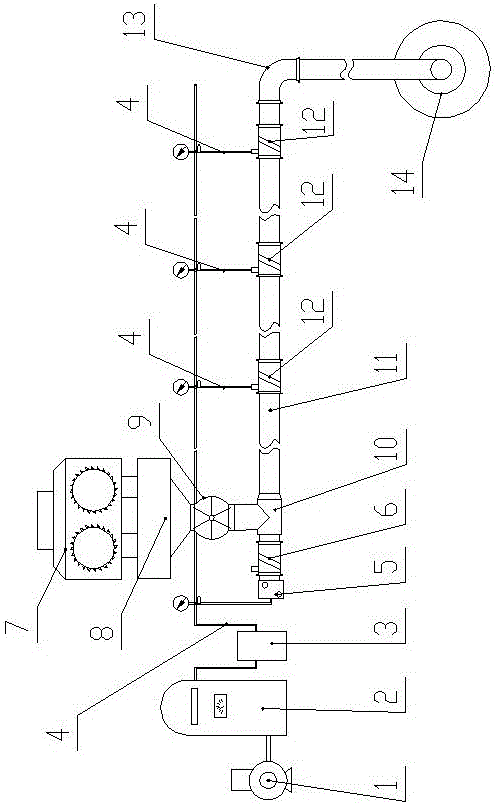

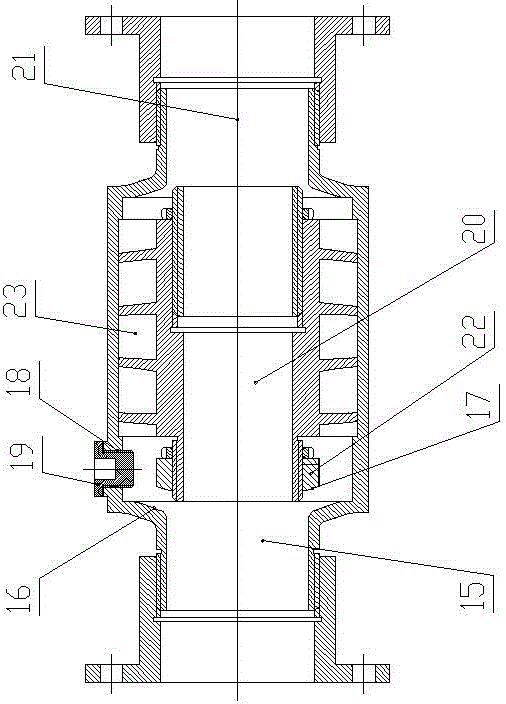

[0022] Such as Figure 1-4 As shown, a mineral particle cyclone pneumatic conveying system of the present invention includes an air supply device, a feed device, a gas delivery pipe 4, a supply spinner 12, an acceleration chamber 10, a material delivery pipe 11 and a material collection device 14, for supplying A swirl flow generation system is provided between the gas device and the acceleration chamber 10;

[0023] The air supply device includes a fan 1, an air storage tank 2 and a dryer 3, the feed device includes a crusher 7, a buffer silo 8 and a rotary feeder 9, and the swirl generation system includes a gas rectifier 5 and an initial starting Spinner 6;

[0024] The air outlet of the fan 1 is connected to the air inlet of the gas storage tank 2, the air outlet of the air storage tank 2 is connected to the air inlet of the dryer 3, and the air outlet of the dryer 3 is respectively rectified with the gas rectifier 5 through the air pipe 4. The air inlet is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com