Large-work-space three-transverse-movement parallel machine tool additionally provided with two redundancy sliding freedom degrees

A work space, three translation technology, applied in metal processing machinery parts, metal processing equipment, manipulators and other directions, can solve the problems of unsatisfactory accuracy, irregular working space, small working space, etc., to improve the motion performance and rigidity, avoid Singular configuration, the effect of increasing workspace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

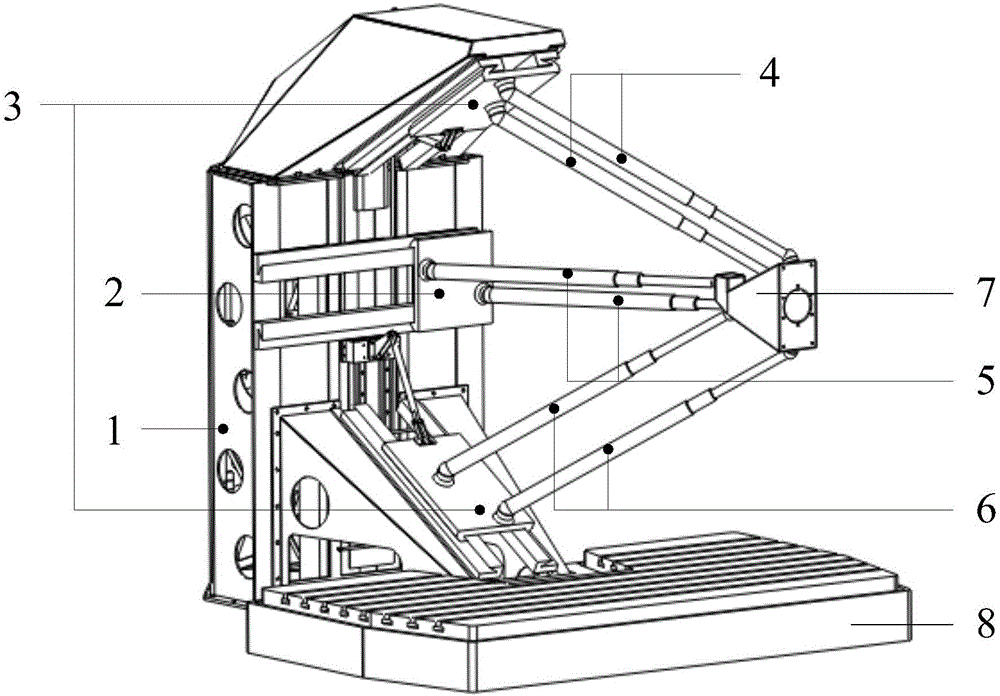

[0022] Combine below Figure 1 to Figure 7 The present invention is described further:

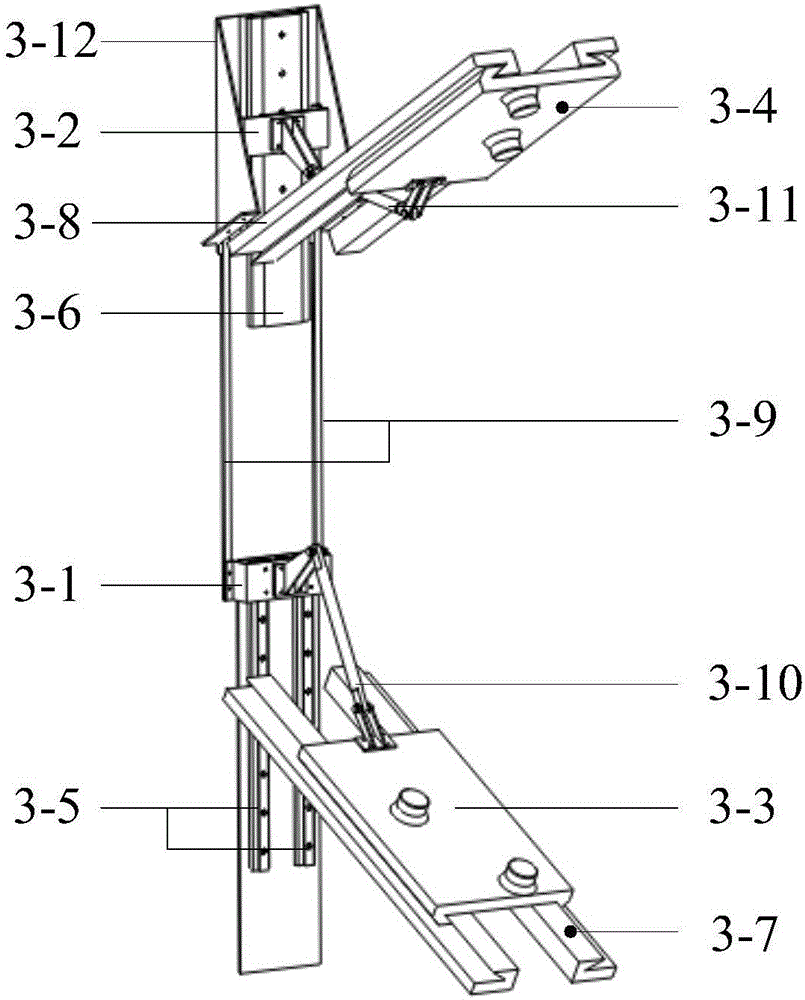

[0023] to combine figure 1 , a large working space three-translational parallel machine tool with two redundant slides in the present invention, including a frame 1, a longitudinal linear module 2, a horizontal two-linkage linear module 3, a first branch chain group 4, a second Branch chain group 5, third branch chain group 6, moving platform 7 and workbench 8;

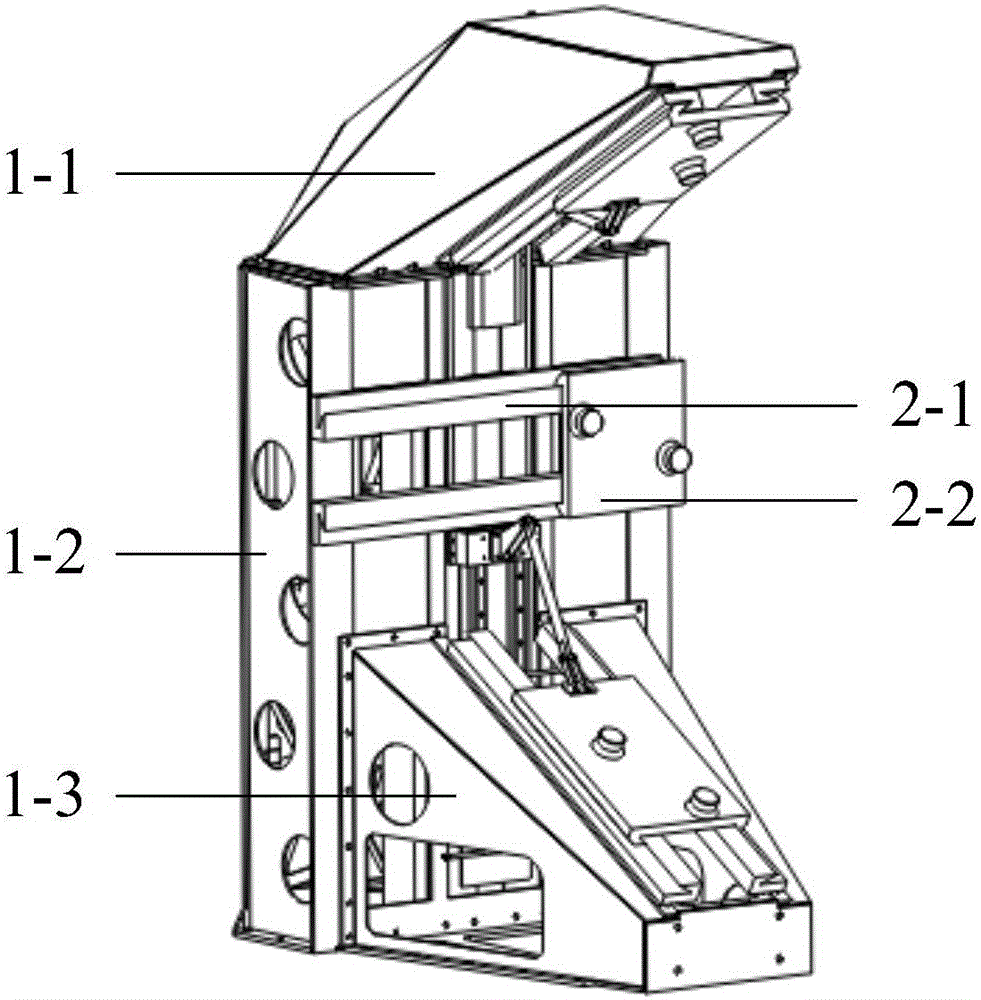

[0024] The frame 1 includes an upper support 1-1, a main column 1-2, and a lower support 1-3; the longitudinal linear module 2 is a single-degree-of-freedom mobile pair, including a fifth guide rail 2-1 and a fifth guide rail 2-1. Five sliders 2-2; the upper end of the main column 1-2 is equipped with an upper support 1-1, the lower end of the mounting plate of the main column 1-2 is equipped with a lower support 1-3, and the other end of the lower support 1-3 Connected with the workbench 8; the longitudinal linear module 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com