A laser selective melting high-efficiency forming device and method

A technology of laser selective melting and forming device, applied in the field of additive manufacturing, can solve the problems of restricting the development of laser selective melting technology and low forming efficiency of laser selective melting technology, and achieve the effect of improving forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

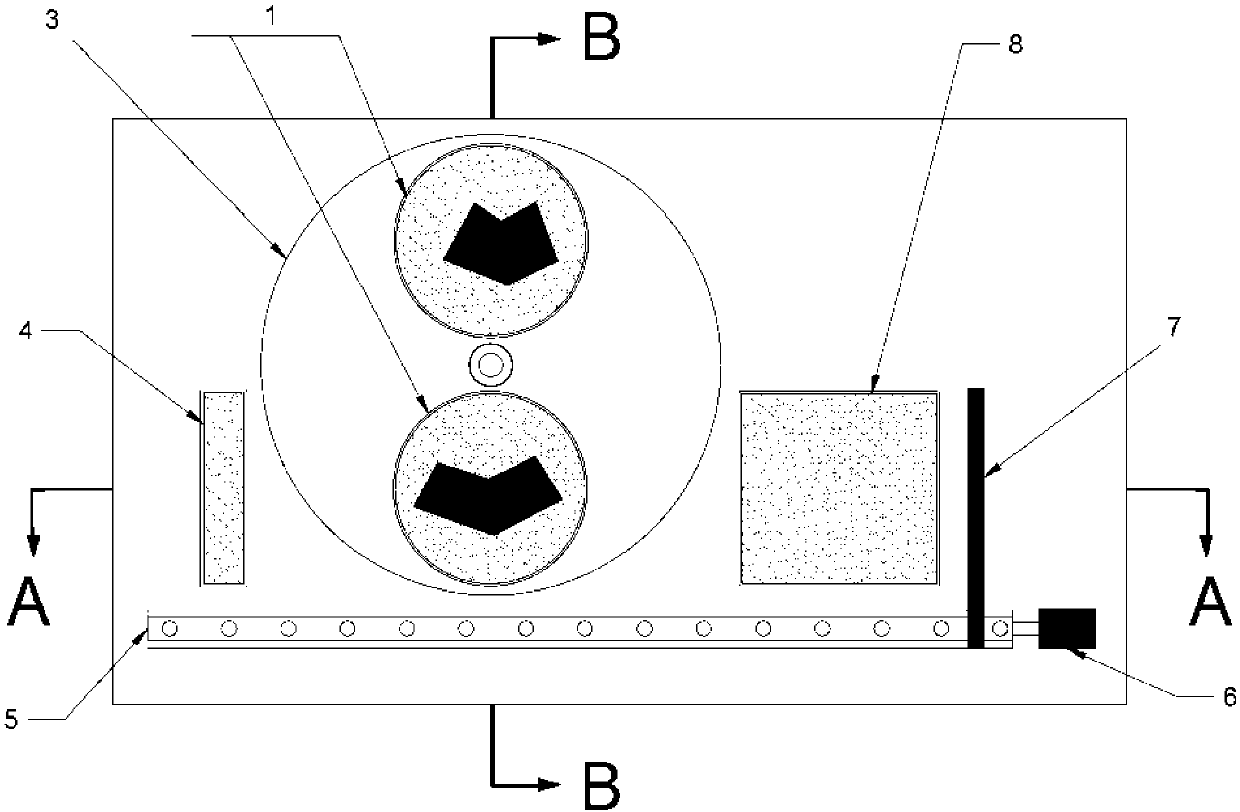

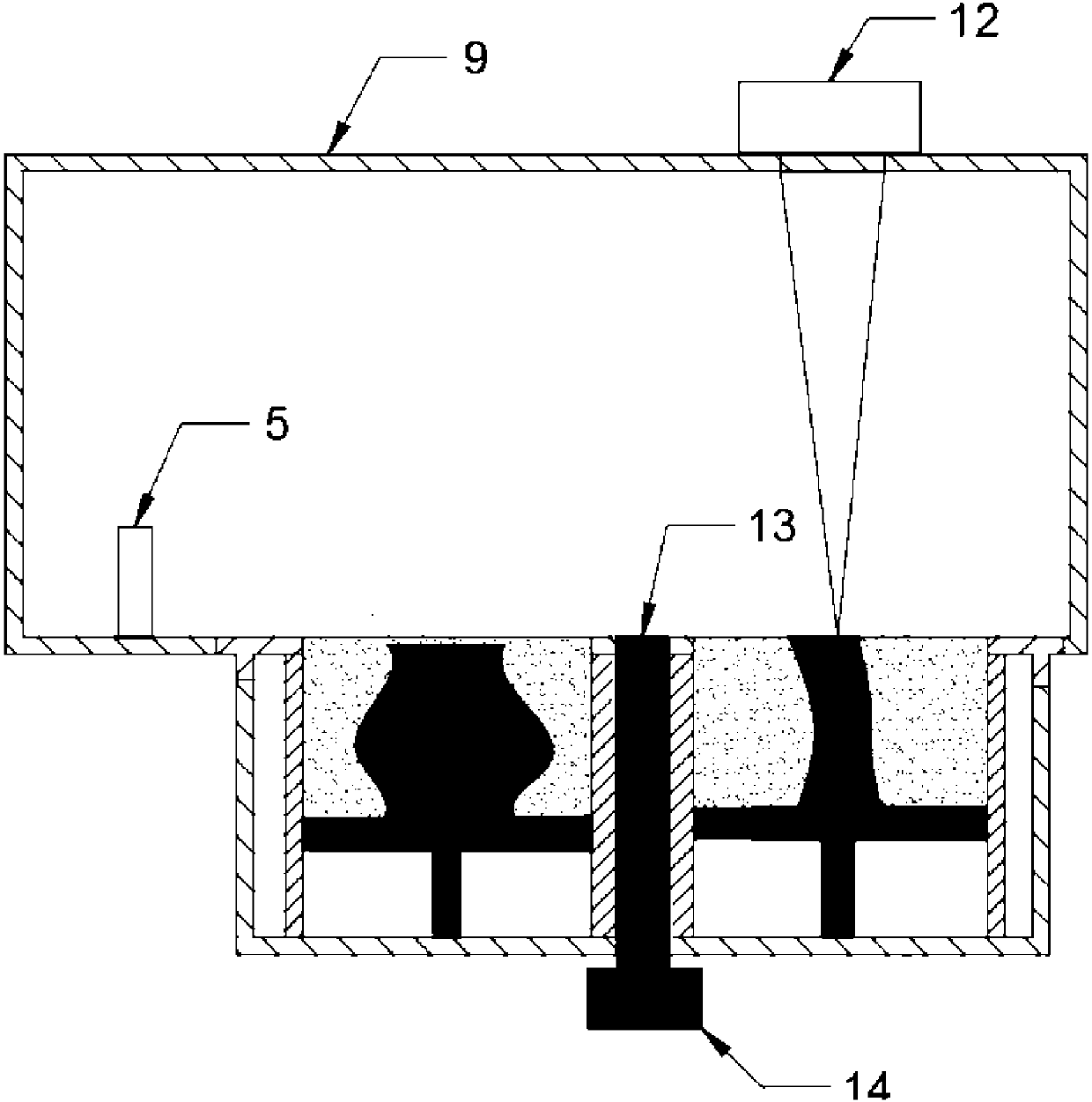

[0027] Such as Figures 1 to 4 shown. The invention discloses a high-efficiency laser selective melting forming device, which comprises a sealed forming chamber 9, a powder material cylinder 8 placed in the sealed forming chamber 9, a linear powder spreading guide rail 5, a powder spreading mechanism 7 on the linear powder spreading guide rail 5, Rotary forming platform;

[0028] The rotary molding platform includes a circular plane 3, and two molding cylinders 1 with the same structure and symmetrically distributed on its periphery are embedded in the circular plane 3; The upper surface of the cylinder is on the same horizontal plane; the center points of the two molding cylinders 1 and the center point of the circular plane 3 are on the same straight line;

[0029] The area covered by the movement track of the powder spreading mechanism 7 on the circular plane 3 is the powder spreading area, and the area below the laser melting molding station is the forming area; that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com